A small metal pipe bending device and its use method

A bending device and a technology for metal pipes, applied in the field of metal pipe bending, can solve the problems of low efficiency, inability to meet construction needs, high labor intensity, etc., achieve a simple overall structure, meet the bending angle, and overcome irregular bending Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

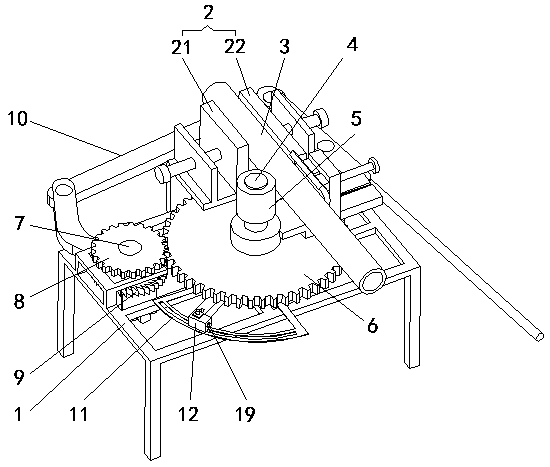

[0034] Such as figure 1 As shown, a small metal pipe bending device of the present invention includes: a frame 1, a fixed end clamping part 2 is fixedly arranged on the frame 1, and the fixed end clamping part 2 includes a first clamping device 21 and the second clamping device 22, the first clamping device 21 and the second clamping device 22 are provided with a circular arc-shaped clamping block (not shown in the figure), so that the clamping of the steel pipe Faster and not easy to deform; the specific structure of the first clamping device 21 and the second clamping device 22 is suitable to realize the clamping of the metal pipe 3, which can be a screw clamping mechanism or other existing clamping devices. The clamping technology will not be described in detail here.

[0035] The frame 1 is also fixedly provided with a first mandrel 4, and the top of the first mandrel 4 is detachably provided with a roller 5, and rollers 5 of different sizes can be selected and installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com