Hemming device for tubular fabrics

A tubular fabric and hemming device technology, applied in textiles and papermaking, mechanical cleaning, high-pressure cleaning, etc., can solve the problems of difficult to guarantee product quality, inaccurate, irregular size, etc., and achieve low cost, convenient use, and neat edges Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

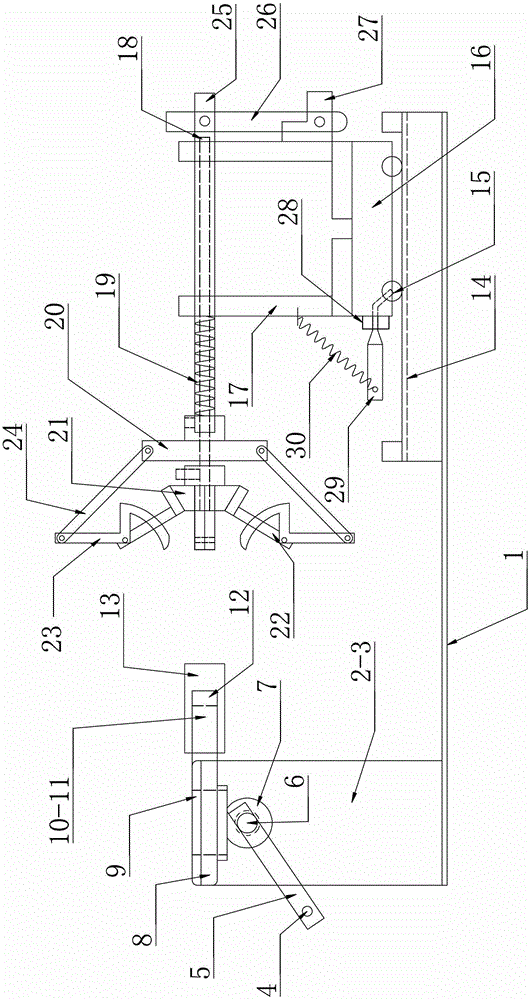

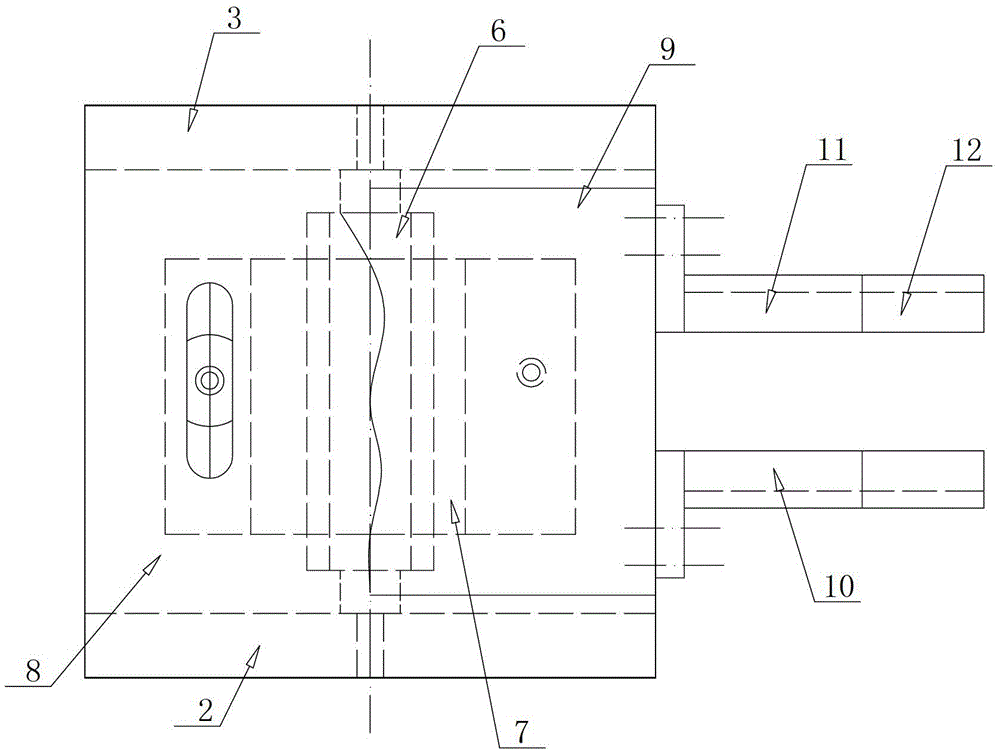

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

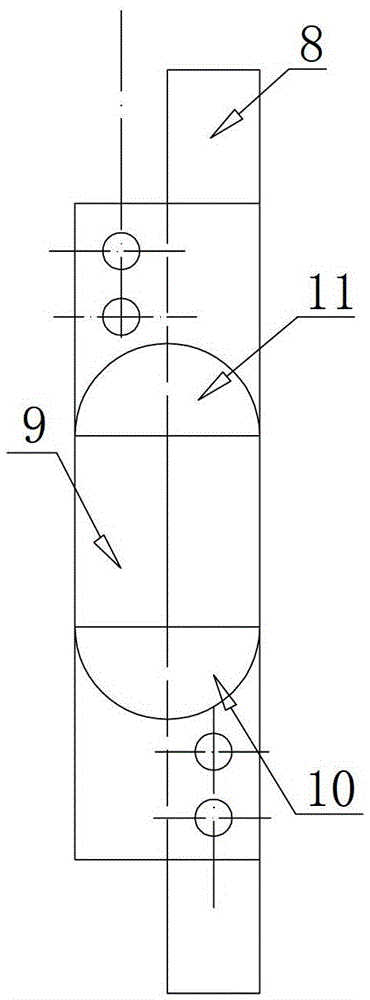

[0025] Such as Figure 1 to Figure 6 As shown, to achieve the purpose of folding in the two sides of the tubular fabric 13, the tubular fabric 13 needs to be placed on an object in a relaxed state, and can be tightened and fixed to facilitate the next step of manipulator folding. The structure that the preferred tubular fabric is entangled and tightened is two wide arms, and the preferred shape of the wide arms is a semi-cylindrical body. The semicircular stainless steel thin-walled pipe 12 is bonded on the semicircular arc surface of the wide arm, so that the manipulator can stretch into the pipe wall when flanging, thereby completing the flanging work.

[0026] During work, the preferred movement mode of the two stretching arms is parallel opening and closing. When closed, install and take out the tubular fabric; when opened, tighten and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com