Metallic material acute plastic deformation extrusion die and using method of die

A severe plastic deformation, extrusion die technology, applied in metal extrusion die, metal extrusion, metal processing equipment and other directions, can solve the problems of extrusion test failure, reverse extrusion, etc., to achieve a wide range of use, easy to use, improve The effect of the test success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

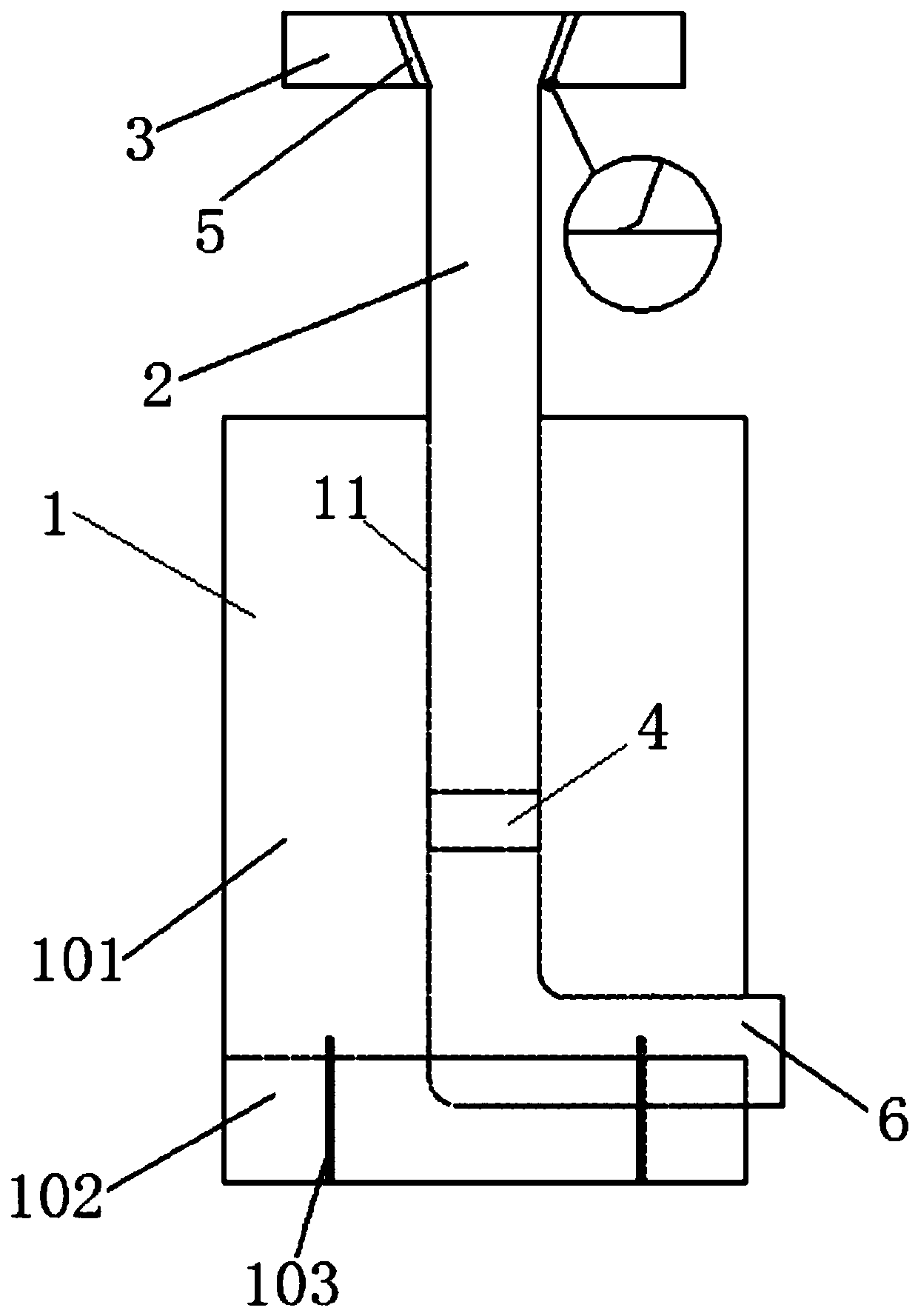

[0051] In Example 1, under room temperature conditions, commercially pure titanium TA1 is processed into a φ20mm rod-shaped extrusion sample, and the rod-shaped extrusion sample is put into the vertical extrusion channel and the horizontal extrusion channel after rough grinding, fineness and polishing In the severe plastic deformation mold with an included angle of 135°; the inside of the extrusion channel is evenly coated with MnS 2 + Graphite milk mixed lubricant, then put the mold with the rod-shaped extrusion sample on the test bench, set the extrusion speed to 3.5mm / s, turn on the testing machine at room temperature for extrusion test, wait for the rod-shaped sample After the deformation is completed, stop the machine, open the extrusion die and take out the deformed extrusion sample.

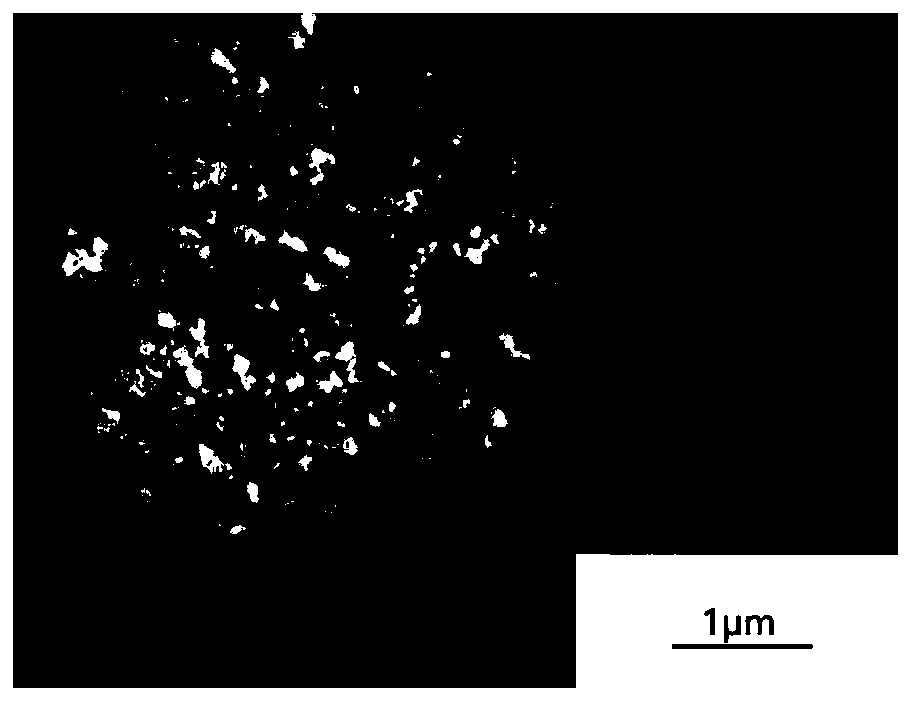

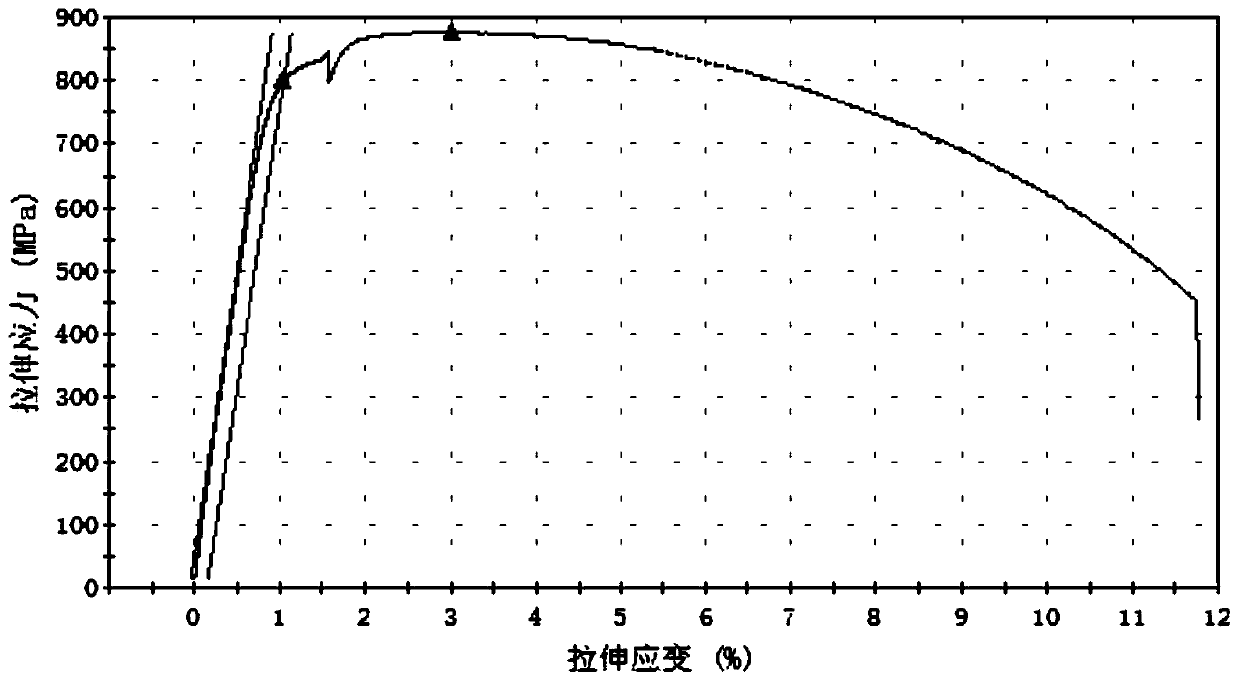

[0052] The deformed extruded sample was prepared as a transmission electron microscope sample, and the structure of the industrial pure titanium sample was observed by the transmission ele...

example 2

[0054] In Example 2, commercially pure titanium is processed into a rectangular plate-shaped sample of 18×20×150 mm at room temperature, and the rectangular plate-shaped sample is put into a vertical extrusion channel and laterally extruded after rough grinding, fineness and polishing In a severe plastic deformation mold with a channel angle of 120°; MnS is evenly coated inside the extrusion channel 2 Lubricant mixed with graphite milk in a certain proportion, then put the extrusion die equipped with a rectangular plate sample on the test bench, set the extrusion speed to 2mm / s, and turn on the testing machine at room temperature for extrusion test After the deformation of the rectangular plate sample is completed, stop the machine, open the mold and take out the extruded sample of industrial pure titanium after extrusion deformation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com