Catalyst for preparing formic acid through electrochemical reduction of carbon dioxide and preparation method thereof

A carbon dioxide and catalyst technology, applied in the field of catalysts, can solve the problems that the catalyst performance needs to be further improved, the catalyst stability is poor, etc., and achieve the effects of high activity and good formic acid selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take a certain amount of copper nitrate dissolved in deionized water to obtain solution A, dissolve a certain amount of BTC in ethanol to obtain B, add A dropwise to B, transfer it to a 100ml reaction kettle, crystallize at 110°C for 8 hours, and cool The product was suction-filtered at lower temperature, washed with 50% ethanol aqueous solution, and dried at 40° C. to prepare Cu-BTC.

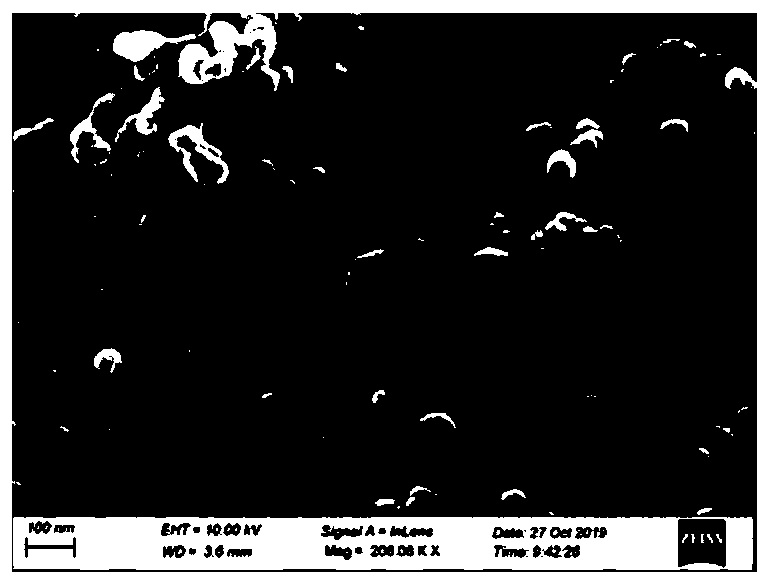

[0039] The stannous oxalate is fully mixed with the prepared Cu-BTC according to a certain ratio (wherein the mass of Cu-BTC is 30%). Then put it in a muffle furnace from room temperature to 600°C at a heating rate of 20°C / min, calcining for 8 hours, and then slowly lowering to room temperature to obtain Sn 0.3 Cu 0.7 O catalyst, the catalyst SEM picture is attached figure 1 shown.

[0040] The prepared catalyst was subjected to constant potential electrolytic reduction at a voltage of -1.7V, the Faraday efficiency was 59.2%, and the current density was 82.4mA / cm 2 .

Embodiment 2

[0042] Dissolve a certain amount of copper nitrate in deionized water to obtain solution A, dissolve a certain amount of BTC in ethanol to obtain B, add dropwise A to B, transfer it to a 100ml reaction kettle, crystallize at 170°C for 24 hours, and cool The product was suction-filtered at lower temperature, washed with 50% ethanol aqueous solution, and dried at 80° C. to prepare Cu-BTC.

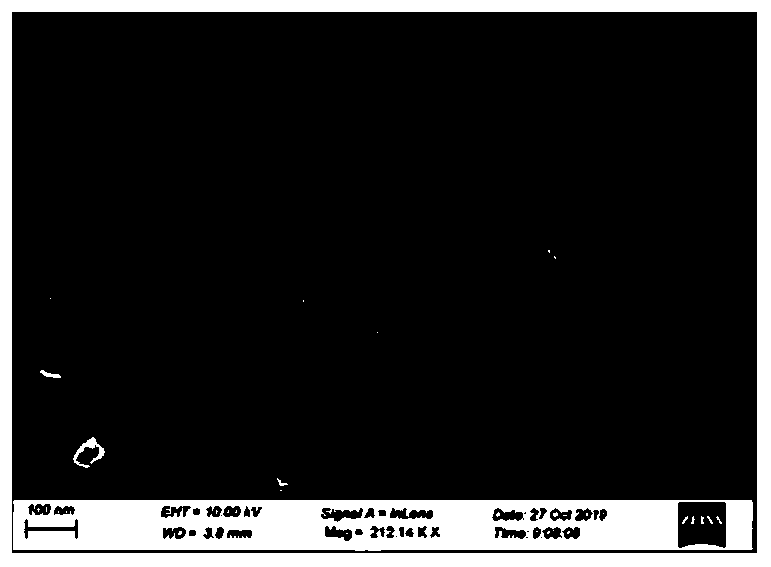

[0043]The stannous oxalate is fully mixed with the prepared Cu-BTC according to a certain ratio (the mass of Cu-BTC is 70%). Then put it in a muffle furnace from room temperature to 500°C at a heating rate of 10°C / min, calcined for 2 hours, and then slowly lowered to room temperature to obtain Sn 0.7 Cu 0.3 O catalyst, the catalyst SEM picture is attached figure 2 shown.

[0044] The prepared catalyst was subjected to constant potential electrolytic reduction at a voltage of 2.3V, the Faraday efficiency was 34.7%, and the current density was 59.4mA / cm 2 .

Embodiment 3

[0046] Dissolve a certain amount of copper nitrate in deionized water to obtain solution A, dissolve a certain amount of BTC in ethanol to obtain B, add A dropwise to B, transfer it to a 100ml reaction kettle, crystallize at 200°C for 14 hours, and cool The product was suction-filtered at lower temperature, washed with 50% ethanol aqueous solution, and dried at 40° C. to prepare Cu-BTC.

[0047] The stannous oxalate is fully mixed with the prepared Cu-BTC according to a certain ratio (wherein the mass of Cu-BTC is 50%). Then put it in a muffle furnace from room temperature to 450 ° C, the heating rate is 8 ° C / min, calcined for 5 hours, and then slowly lowered to room temperature, that is, Sn 0.5 Cu 0.5 O catalyst, the catalyst SEM picture is attached image 3 shown.

[0048] The prepared catalyst was subjected to constant potential electrolytic reduction at a voltage of 4V, the Faraday efficiency was 19.1%, and the current density was 78.3mA / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com