Propellant liquid level high-precision laser measuring device

A laser measurement, high-precision technology, used in measurement devices, liquid/fluid solid measurement, lubrication indicating devices, etc., can solve the problems of slow measurement speed, high potential risk, small number of measurement points, etc., to increase the amount of information acquisition, convenience Distributed installation, the effect of reducing installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

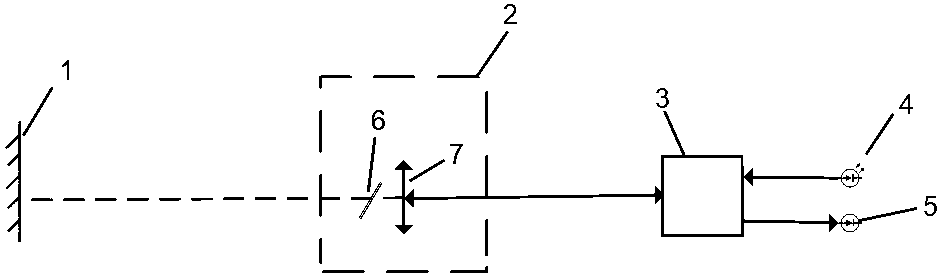

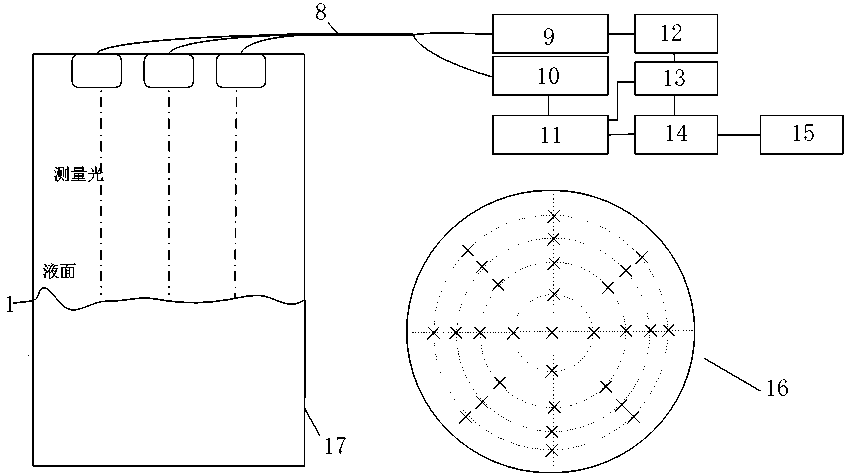

[0020] like figure 2 As shown, the top of the propellant storage tank 17 is evenly arranged with multi-channel optical fiber probes 8, the semiconductor laser 9 adopts a vertical cavity surface laser, the main controller 14 adopts a high-performance, low-power ARM processor, and the timing generator 13 adopts a programmable gate The array, according to the code of the probe installation position, controls the laser at the corresponding position to emit the laser beam. The photodetector 10 uses an APD detector to receive echo signals in sequence. The main controller 14 uses the time-to-digital converter TDC chip 11 to obtain the single-channel measurement time difference , remove the internal transmission delay of the system, and get the round-trip flight time t of the laser in the air, according to (c is the speed of light) to obtain the liquid level height s; after a round of scanning measurement, the liquid level information of multiple points on the liquid surface is obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com