Drying device for machine part production

A technology for drying devices and mechanical accessories, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of poor air flow effect of sheet metal parts, long drying time, and affecting the production efficiency of accessories, etc., to achieve Improve the effect of heat transfer, increase the effect of deformation, and maintain the effect of ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

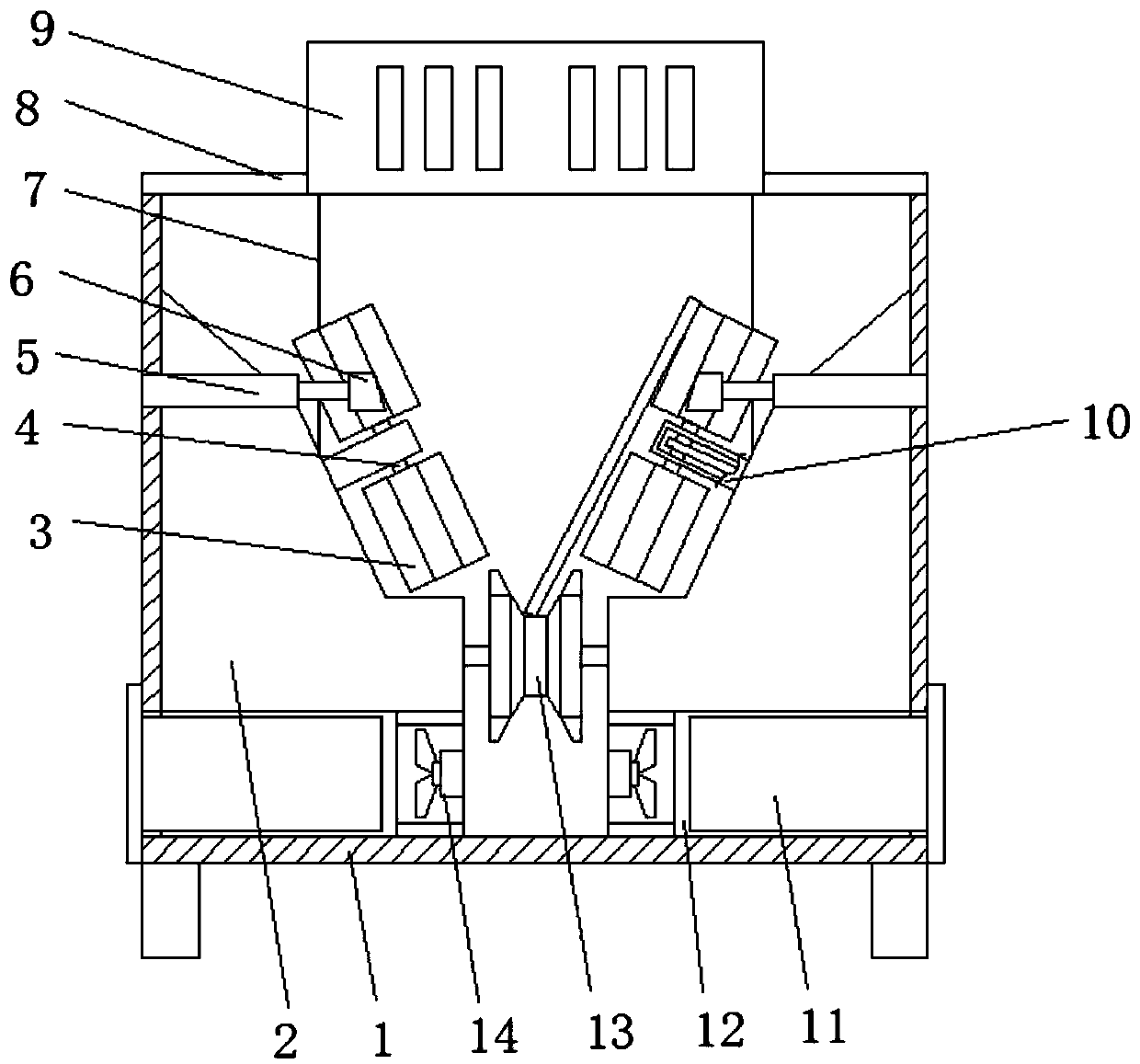

[0029] refer to Figure 1-4 , a drying device for the production of mechanical parts, comprising a box body 1, the top of the box body 1 is fixedly installed with a box cover 8, and the two ends of the box body 1 are respectively provided with material openings 7, and both inner sides of the box body 1 are fixed. A support frame 2 is installed, and a plurality of exhaust passages 12 are formed between the support frame 2 and the bottom inner wall of the box body 1, a conveying wheel 13 is installed between the two support frames 2 through bearings, and the two support frames 2 are mutually A plurality of connecting frames 10 are fixedly installed on the adjacent side, the end of the connecting frame 10 is installed with a rotating shaft 4 through a bearing, and both ends of the rotating shaft 4 are fixedly installed with a wiping mechanism 3, and the inner part of the supporting frame 2 is fixedly installed There is a driving mechanism, and the driving mechanism is connected w...

Embodiment 2

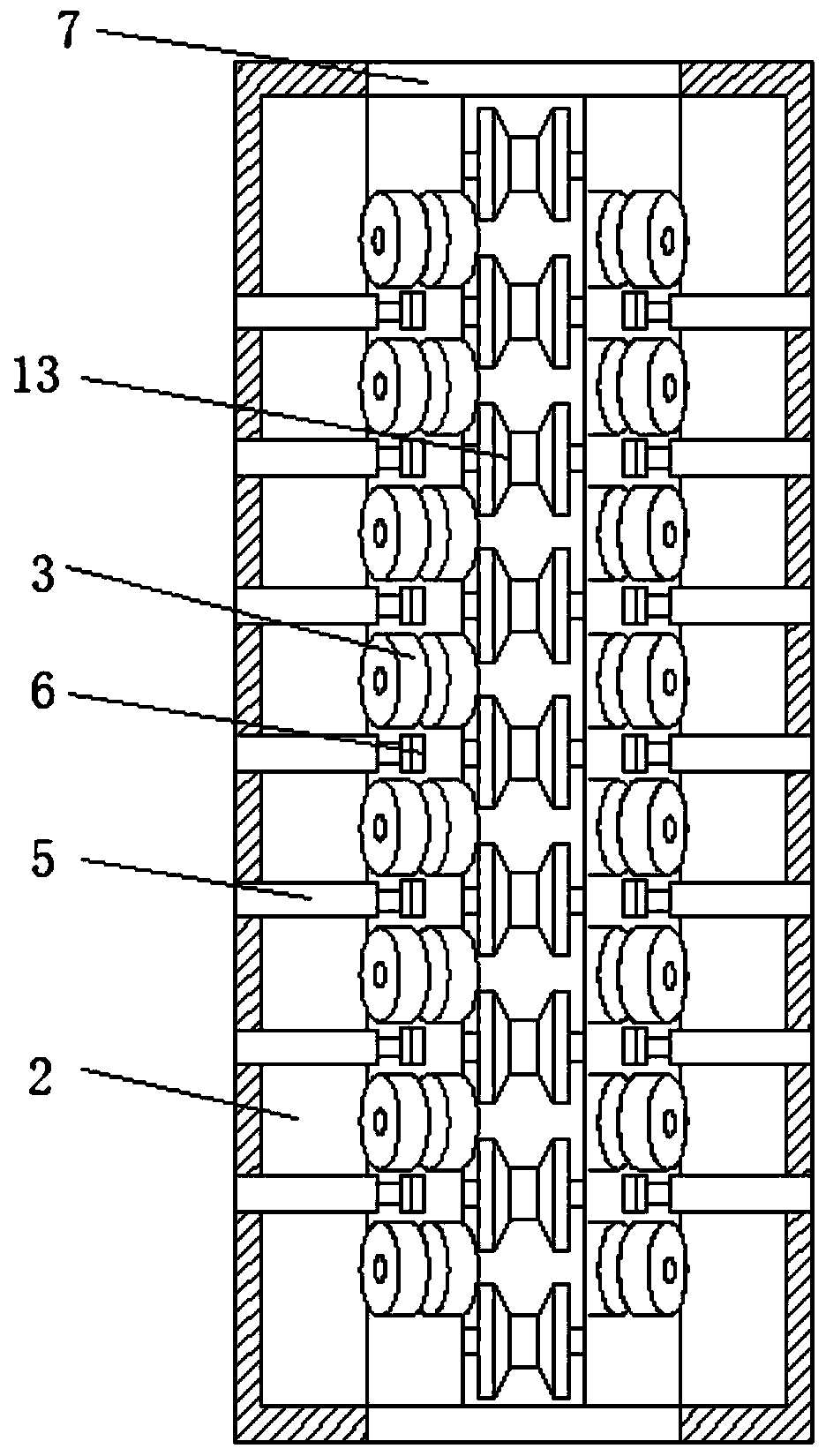

[0036] refer to Figure 1-3 and Figure 5 , a drying device for the production of mechanical parts, the wiping mechanism 3 includes a secondary connecting column 36 and a plurality of sponge wheels 34 sleeved on the outside of the secondary connecting column 36, and there are two adjacent sponge wheels 34. gap.

[0037] The wiping mechanism 3 further includes a fleece wheel 35 sleeved on the outer side of the auxiliary connecting column 36 , and the fleece wheel 35 and the sponge wheel disc 34 are staggered.

[0038] In this embodiment, the wiping mechanism 3 is constituted by staggered velvet wheels 35 and sponge wheels 34 that are sleeved on the outside of the auxiliary connecting column 36. When the wiping mechanism 3 transports the sheet metal parts, the velvet wheel 35 and the sponge wheel 34 The gap between them ensures the effect of hot air circulation, and the outer surface of the flannel wheel 35 can effectively wipe the surface of the sheet metal parts, so as to av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com