Prefabricated reinforced concrete gate slot unit for rcc dam and construction method of gate slot

A technology of reinforced concrete and roller compacted concrete, applied in dams, water conservancy projects, sea area projects, etc., can solve problems such as occupying a straight line construction period and affecting the construction progress of roller compacted concrete dams, so as to ensure the construction period, avoid construction difficulties, and fast construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

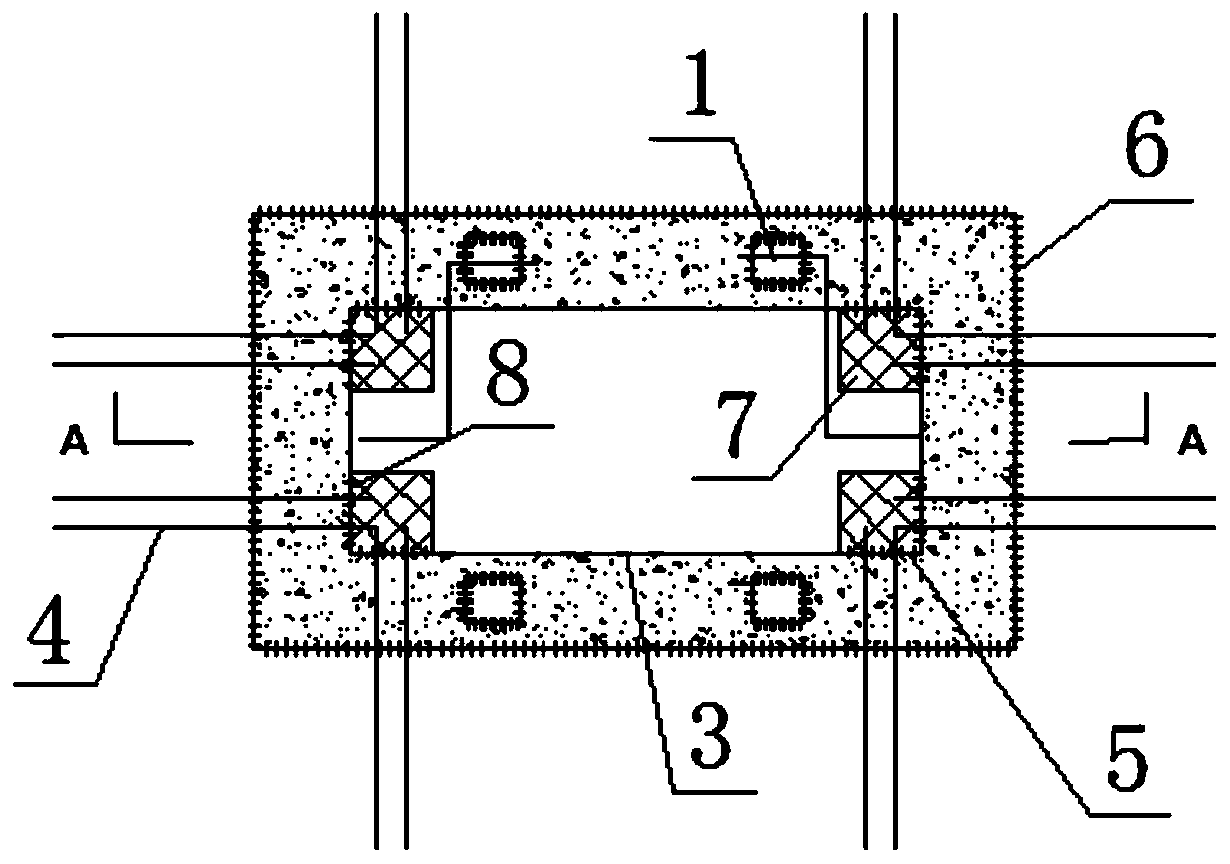

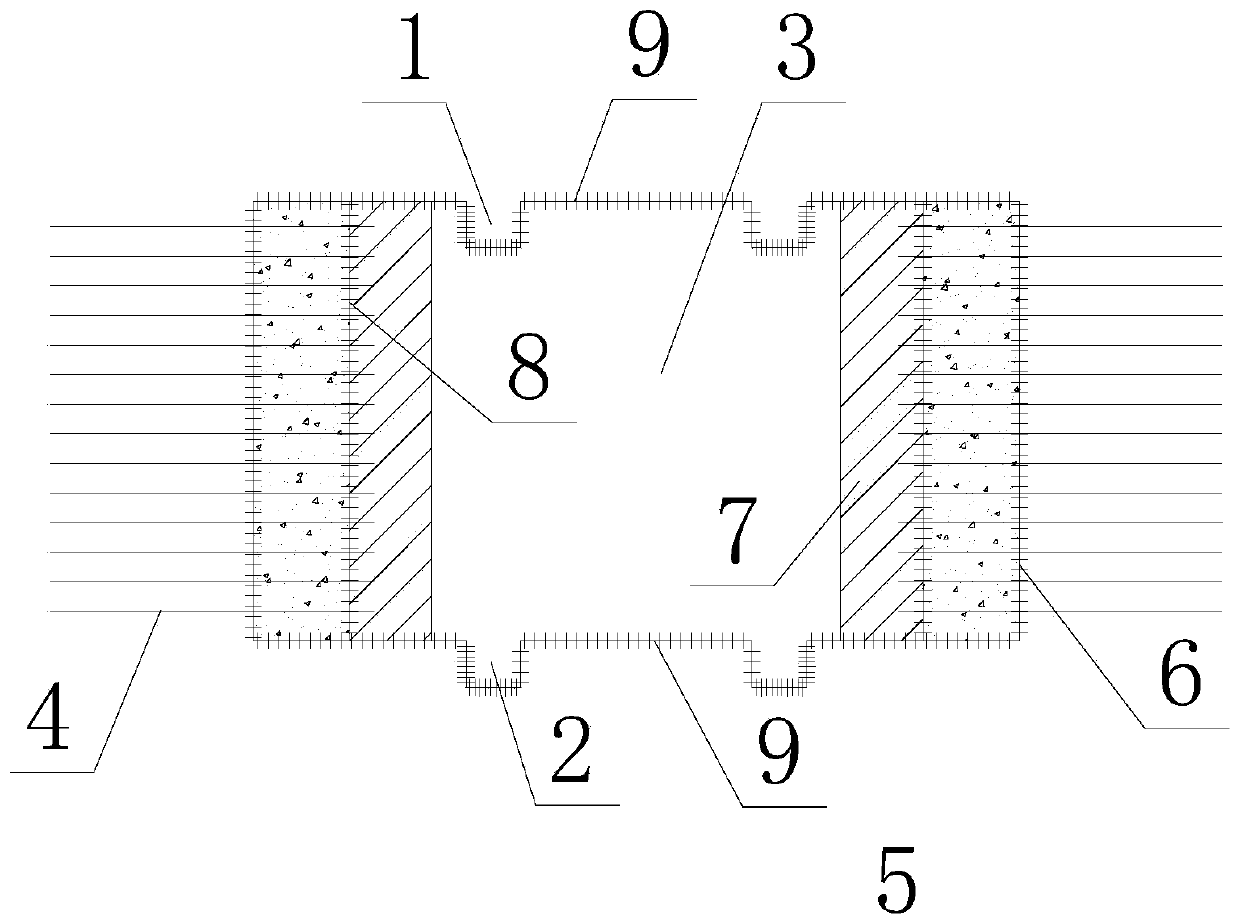

[0016] Such as Figure 1-2 As shown, the prefabricated reinforced concrete door slot unit for the roller compacted concrete dam of the present invention, according to the design size, prefabricated the upper and lower bottomless square tube-shaped prefabricated reinforced concrete door slot unit 3 in the prefabrication plant, and the prefabricated reinforced concrete door slot unit 3 There are at least one slot 1 on the two long sides of the top surface of the corresponding prefabricated reinforced concrete door slot unit 3. The two long sides of the bottom surface of the corresponding prefabricated reinforced concrete door slot unit 3 are respectively equipped with plugs 2 that match the position and shape of the slot 1. The four inner corners of the prefabricated reinforced concrete door slot unit 3 are provided with multiple groups of through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com