An airbag type drainage body and its construction method

A drainage body and airbag technology, applied in infrastructure engineering, construction, soil protection, etc., can solve the problems of inability to form vertical drainage channels, affect drainage rate, and construction difficulties, so as to ensure vacuum transmission and accelerate drainage rate , The effect of reducing the drainage cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] For the dredging project of the reservoir, cutter suction dredgers are used, and the dredging mud with high water content is transported by the centrifugal mud pump to the mud pool. The area of the mud pool is about 50m×100m and the depth is 2m.

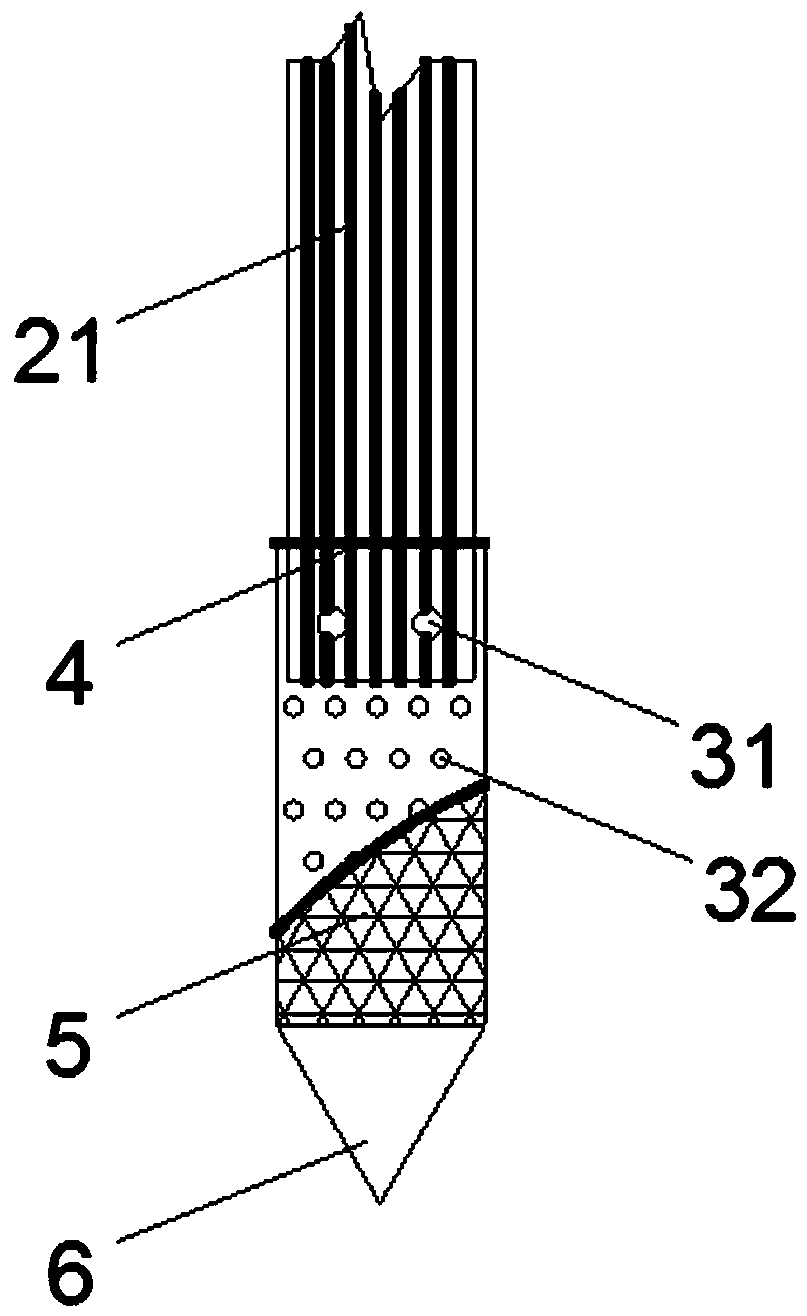

[0037] The plastic drainage board 2 adopts a B-type drainage board with a width of 100 mm and a thickness of 5 mm, and its filter membrane adopts O 95 <0.075mm;

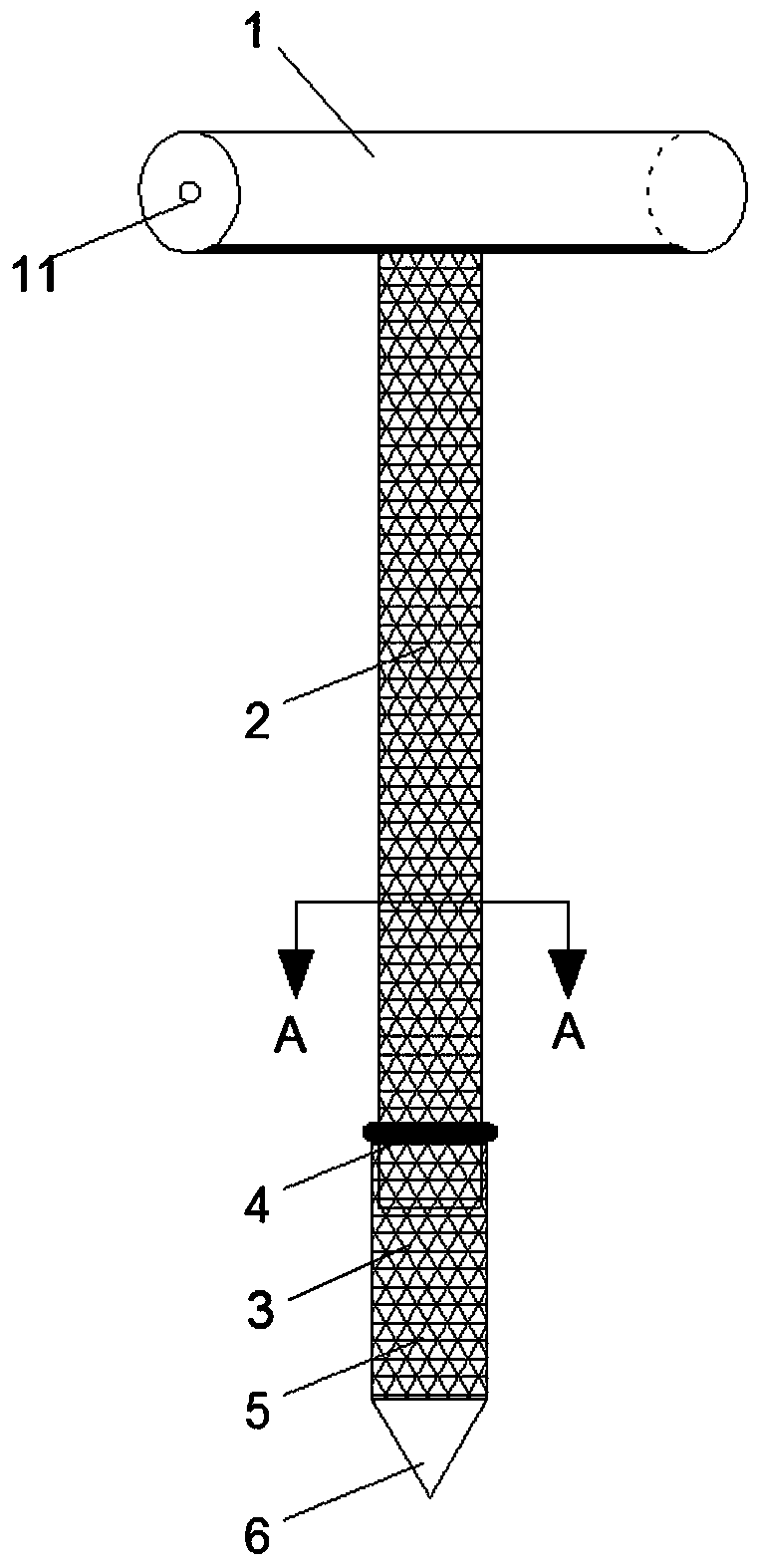

[0038] The polyvinyl chloride film commonly used in vacuum preloading is selected as the material of the airbag 1. The length of the airbag is 10m, and the diameter of the airbag is 1m. Each airbag is equipped with 9 plastic drainage boards with a distance of 1m and a length of 2m.

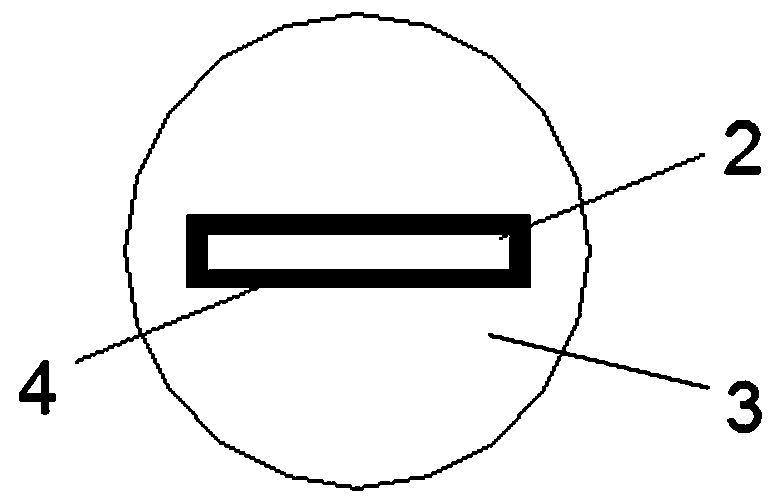

[0039] Drain board shoe 3 is welded by two steel plates with a length of 50cm. There is a rectangular groove between the two steel plates. The length of the rectangle is 105mm and the width is 10mm. , the plastic drainage board can be inserted into the rectangular groove, and the airt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com