Double-layer SMA bridge deck pavement system of steel truss-concrete composite beam bridge and construction method

A bridge deck paving and concrete technology, used in bridges, bridge parts, bridge construction and other directions, can solve the problems of easy rutting, slippage, low construction requirements, insufficient shear strength, etc., to ensure construction quality and improve pavement. Accuracy and the effect of improving pavement quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the embodiments. The following examples are illustrative only to aid in the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, several improvements and modifications can also be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

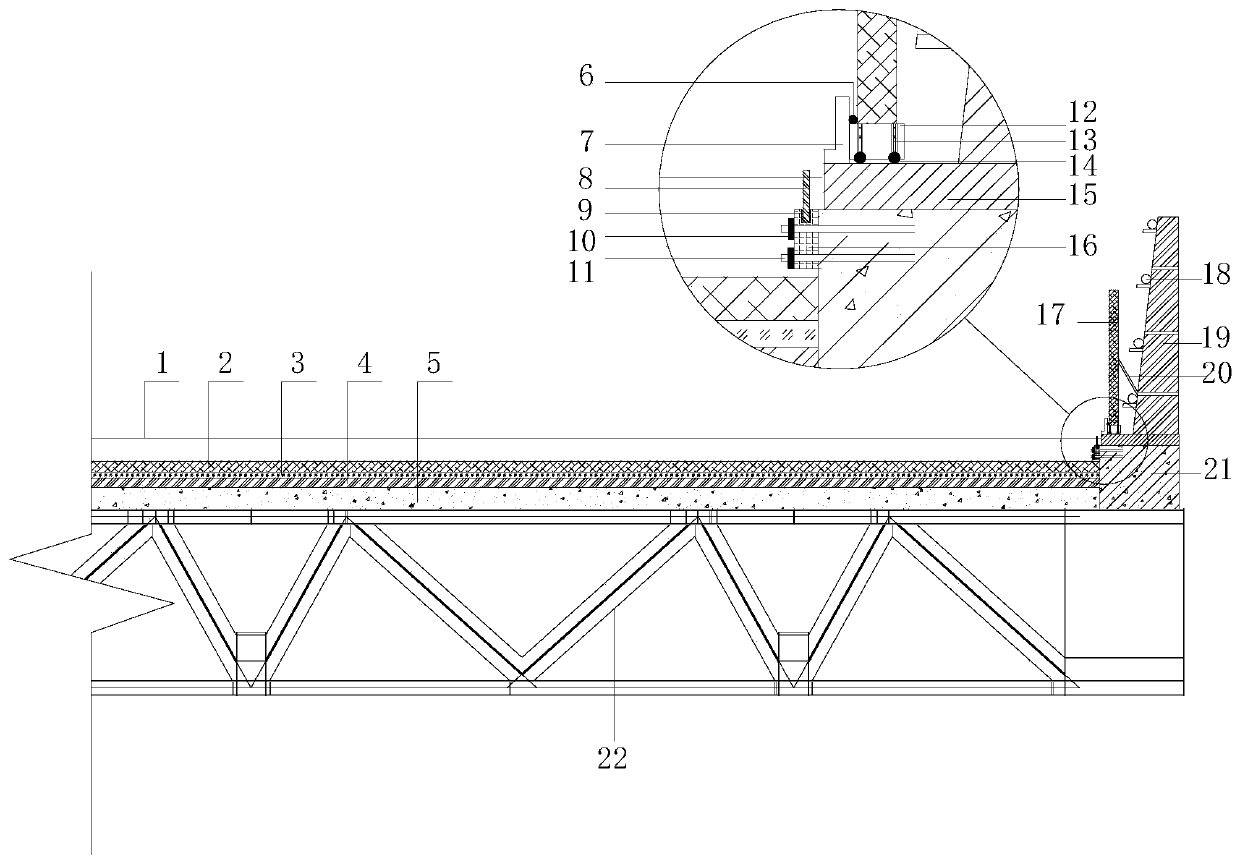

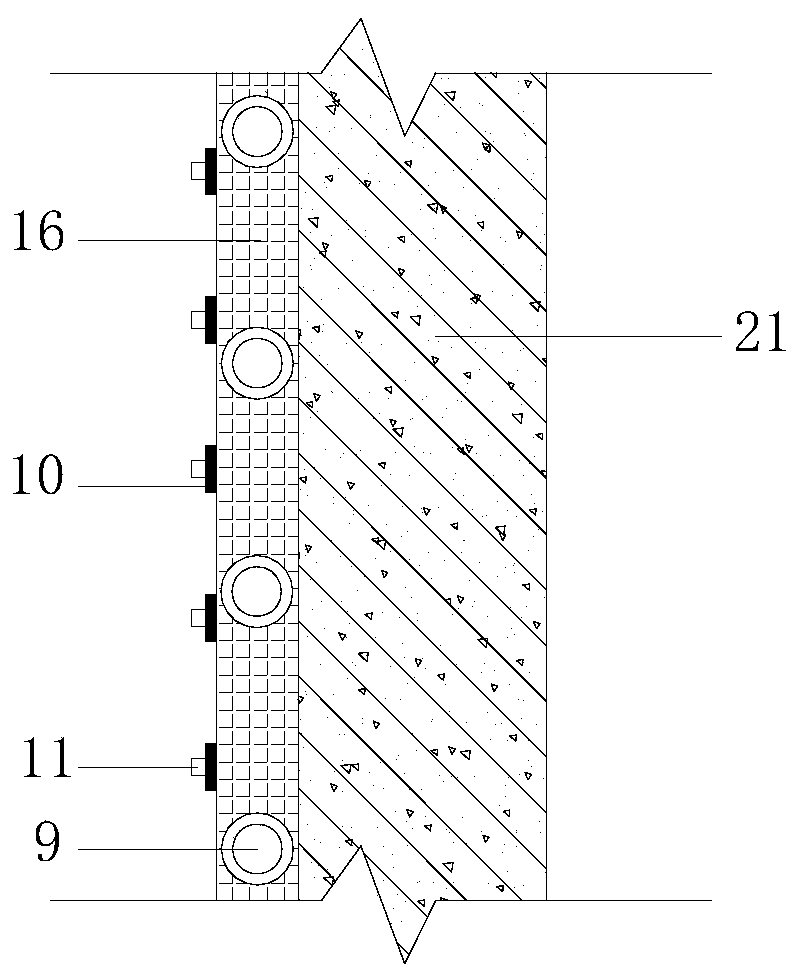

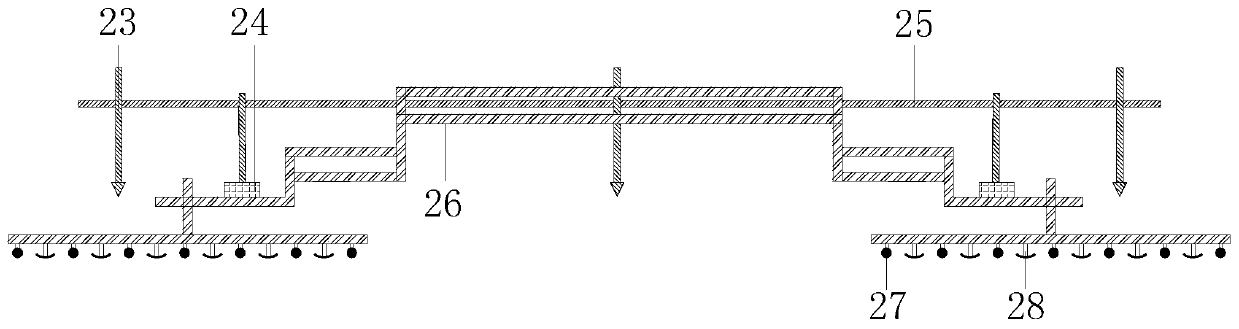

[0036] refer to Figure 1-5 As shown, the double-layer SMA deck pavement system of the steel truss-concrete composite girder bridge is mainly composed of a steel truss bridge, a girder bridge pavement layer, a steel guardrail, a fixed reference suspension system and a contact spanning floating balance beam system. etc. composition.

[0037] Before construction, first check the appearance of the steel bridge deck to ensure that the surface is free of welding flas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com