Double head OSB (oriented structural board) paving machine

A paving machine and paving technology, applied in the direction of household components, flat products, household appliances, etc., can solve the problem that there is no way to achieve a single paving head graded paving, affecting the service life of paving quality equipment, carbon steel sticky materials, etc. problems, to achieve the effect of improving pavement quality, saving costs and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

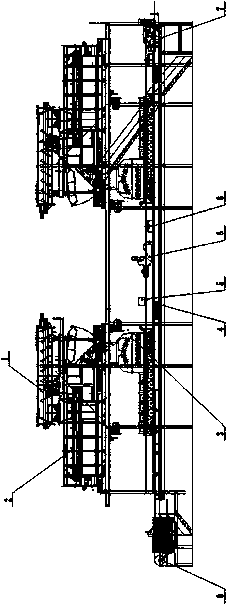

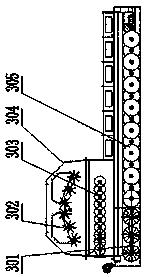

[0018] see Figures 1 to 2 It is a front view of the present invention and a structural schematic diagram of the directional paving head 3, which includes a swinging screw conveyor 1, a metering box 2, a directional paving head 3, a metering belt scale 4, a moisture content measuring instrument 5, a core lamination device 6, a steam Steam spraying device 7, permanent magnet iron remover 8, paving bottom conveyor 9, directional paving head 3 including star paving roller 301, spreading roller 302, cage mouse roller 303, paving head shell 304, disc carding Roller group 305, some spreader rollers 302 are arranged on the inner side upper part of pavement head shell 304, the two ends of some spreader rollers 302 are connected with pavement head shell 304 through several bearings respectively, the bottom of some spreader rollers 302 is provided with several The two ends of the cage rollers 303 and the cage rollers 303 are respectively movably connected with the paving head shell 304 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com