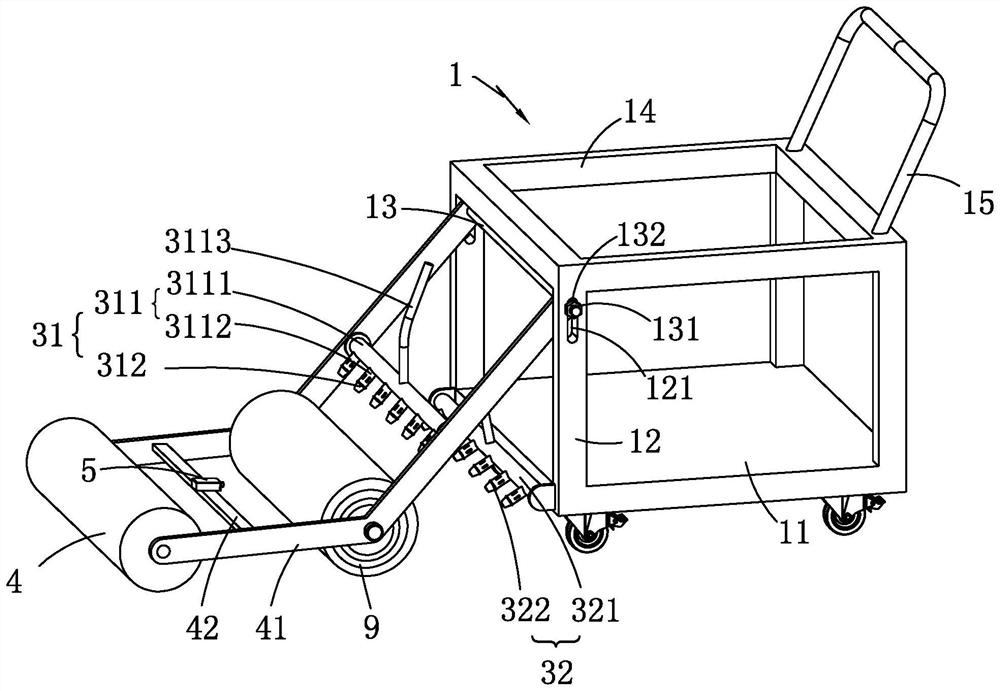

A kind of asphalt waterproof coiled material paving equipment and paving method

A technology of asphalt waterproof membrane and waterproof membrane, which is applied in bridge construction, erection/assembly of bridges, construction, etc., and can solve the problem of reducing the quality of waterproof membrane pavement, cooling, and affecting the bonding quality of waterproof membrane and base layer, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0076] figure 2 A flow chart of the method for paving asphalt waterproof coiled material in the embodiment of the present invention is shown.

[0077] The paving method utilizes the asphalt waterproof coiled material paving equipment in Embodiment 1 to complete the paving, and the paving includes:

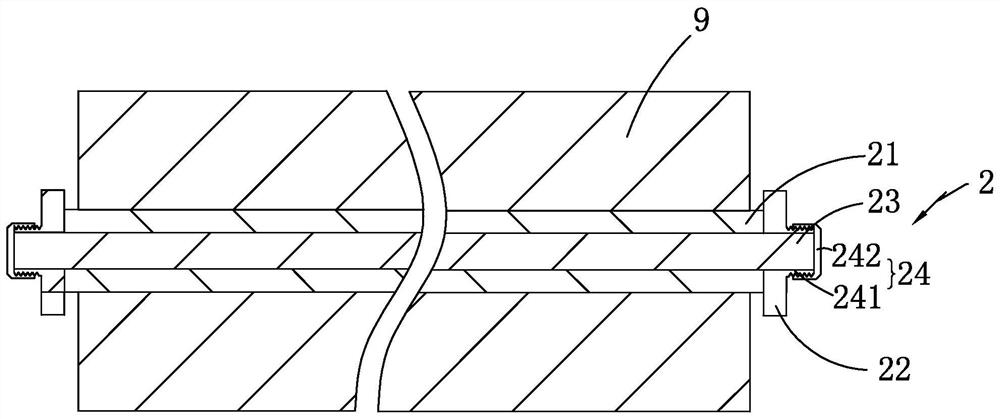

[0078] Step 1. Roll the waterproof membrane 9 on the reel 21 and install it on the drawbar 22. Lift the waterproof membrane 9 to the starting end of the pavement, unfold the waterproof membrane 9 for about 1m, and align the long and short directions. lap seams;

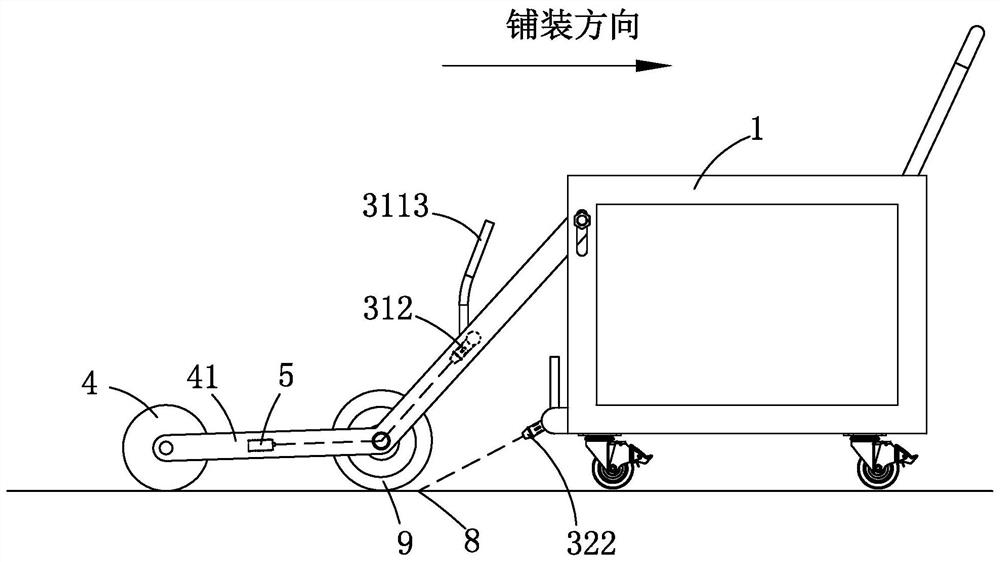

[0079] Step 2. One person pulls up the unfolded waterproof membrane 9 to a certain height, and then another person holds a blowtorch to spray flame on the bottom surface of the waterproof membrane 9. When spraying, the blowtorch should be aligned with the waterproof membrane 9 and the base layer 8, after the hot melt adhesive on the bottom surface of the waterproof membrane 9 is melted, quickly paste the waterproof memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com