a printing device

A printing equipment and printing room technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problem of not having the ability to automatically clamp liquid ink in various sizes of printing paper, automatically control the input printing paper cutting ability, etc., and achieve reliable connection. , to achieve the effect of low cost, convenient inspection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

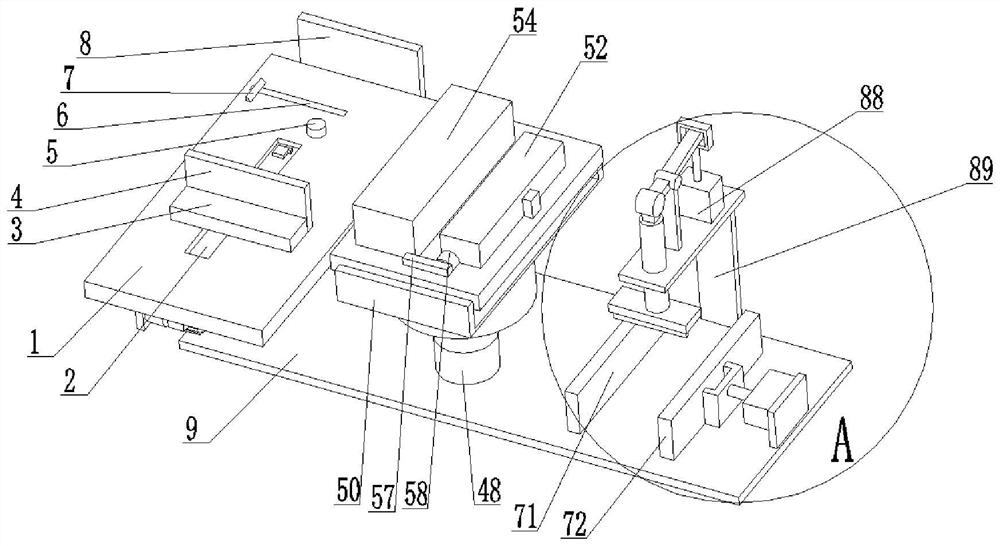

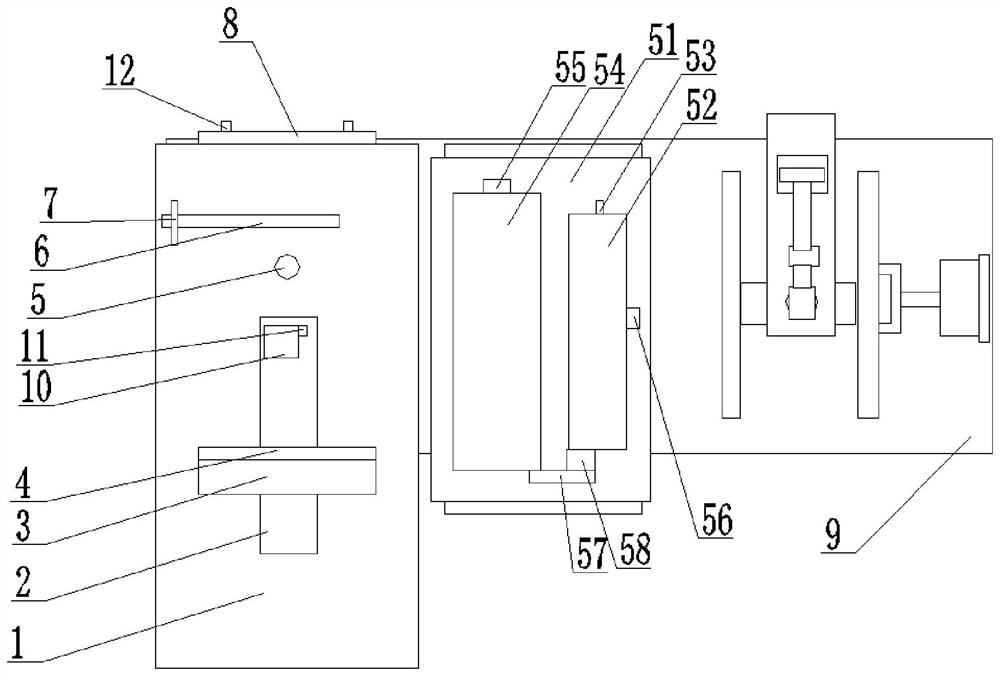

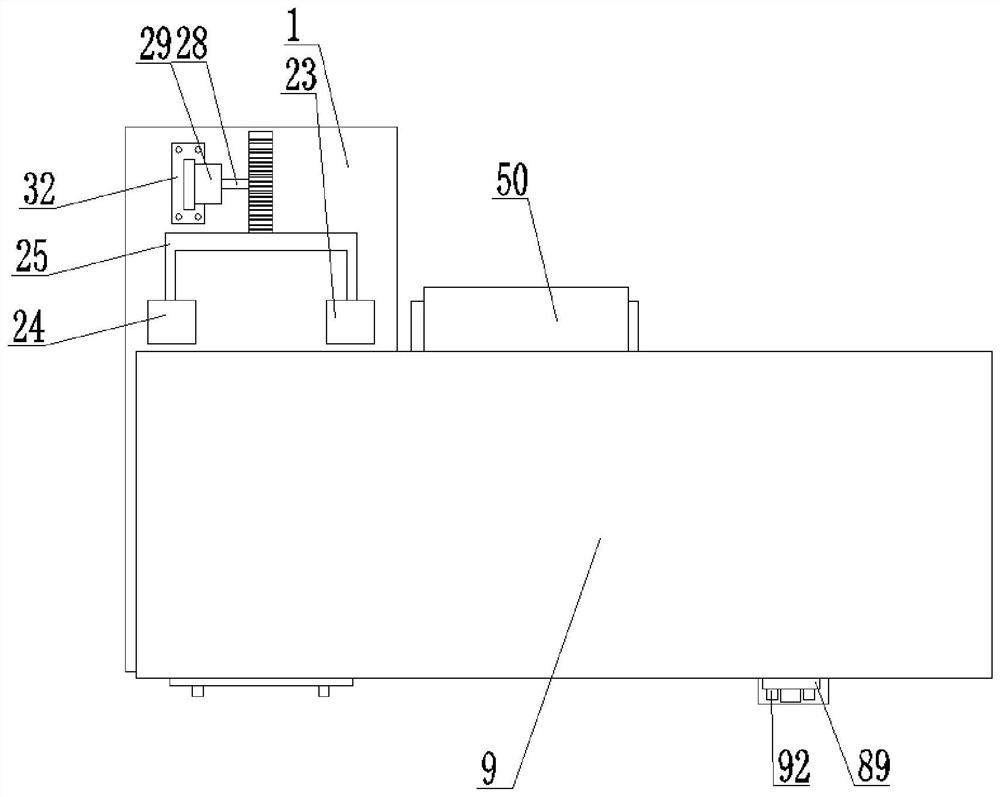

[0033] refer to Figure 1 to Figure 14 A printing device provided by the present invention includes a receiving plate 1, a base plate 9, a printing chamber 50, and a control unit 56. The top surface of the receiving plate 1 is provided with a guide groove 2 and a sliding guide rail 6. The guide groove The top of 2 is provided with a tailgate 4, and the tailgate 4 can move along the length direction of the guide groove 2, and the rear side of the tailgate 4 is fixed with a bar magnet 3, and the bar-shaped The magnetism at the bottom of the magnet 3 is S pole, the inside of the guide groove 2 is provided with a buzzer 10, the side of the buzzer 10 is provided with a light sensor 11, and the top of the sliding guide rail 6 is provided with a Push block 7, the front side of the receiving plate 1 is fixed with the front baffle 8 through the first series of bolt groups 12, the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com