Dispensing subsequent glue removing device for electronic component

A technology for electronic components and dispensing, which is used in grinding drive devices, grinding/polishing safety devices, grinding workpiece supports, etc. problems, to achieve the effect of increasing the glue removal efficiency, strong practicability and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] refer to Figure 1~3 , in an embodiment of the present invention, a dispensing and subsequent glue removal device for electronic components includes a fixed bottom plate 1, a support frame 20 is installed on both sides of the upper end of the fixed bottom plate 1, and a fixed rack 19 is installed on the top of the support frame 20, A guide column 12 is installed between the upper ends of the support frame 20, and the middle part of the guide column 12 is slidably connected with a sliding block 22. The sliding block 22 can move left and right along the guide column 12, and a bearing seat 21 is installed inside the sliding block 22, and the bearing seat 21 A rotating shaft 29 is installed inside, and the rotating shaft 29 can rotate along the bearing seat 21. The upper end of the rotating shaft 29 is equipped with a movable gear 18 that meshes with the fixed rack 19, and the bottom end of the rotating shaft 29 is equipped with a glue removal grinding wheel 28. The glue re...

Embodiment 2

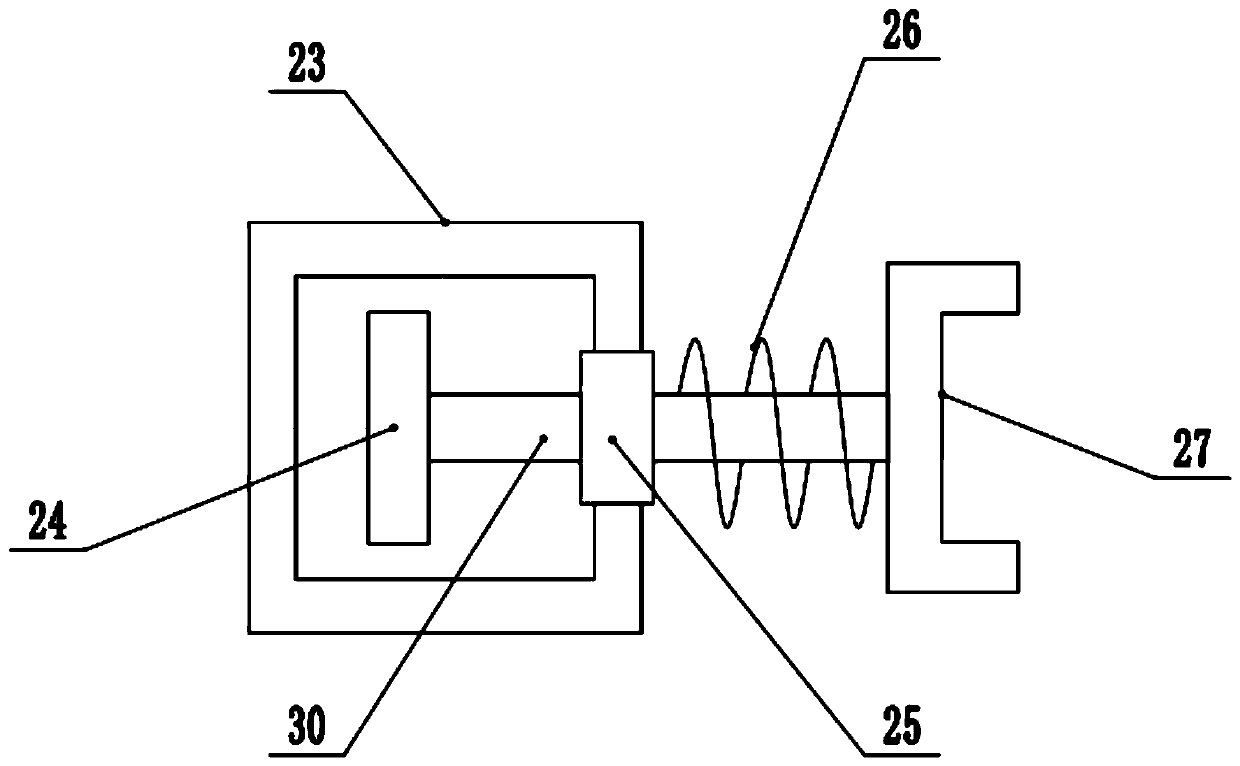

[0030] In another embodiment of the present invention, the difference between this embodiment and the above embodiment is that the positioning and clamping mechanism 17 includes a fixed frame 23, a guide block 25 is installed in the middle of the fixed frame 23, and a clip is installed in the middle of the guide block 25. Clamping rod 30, clamping rod 30 inboard positioning frame 27 is installed, and baffle plate 24 is installed on the outside of described clamping rod 30, and clamping rod 30 outside between described positioning frame 27 and guide block 25 is provided with spring 26, and described The clamping rod 30 can move left and right along the guide block 25 , and can be limited left and right under the action of the spring 26 , so as to remove glue from the electronic components that need to be glued.

[0031]In the present invention, when working, the electronic components are placed on the positioning frame 27 on the positioning and clamping mechanism 17, and the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com