Pre-processing equipment used before self-leveling cement construction

A processing equipment and pre-processing technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as unfavorable heat dissipation, large area of wet ground, unfavorable construction, etc., to achieve the effect of improving equipment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

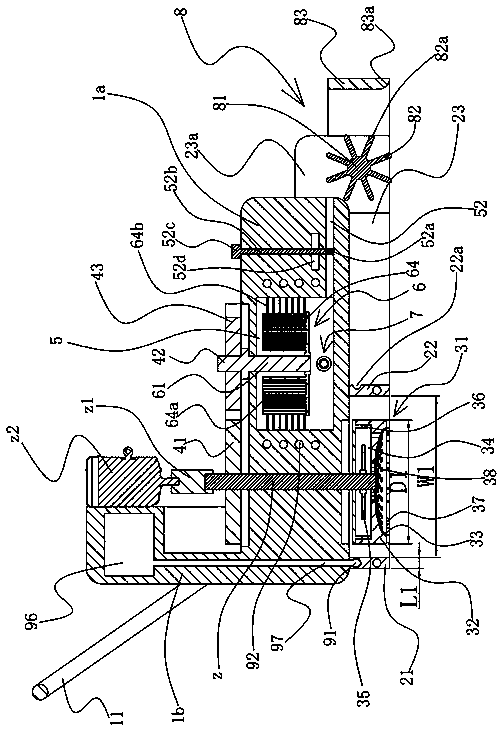

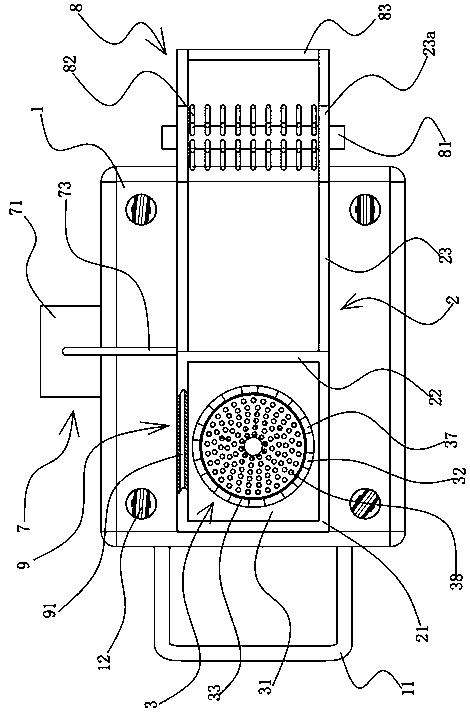

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a self-leveling cement pre-processing equipment before construction includes a main frame 1. In this device, the main frame 1 can be set in an L shape, that is, it includes horizontally distributed horizontal plates 1a and vertical plates perpendicular to the horizontal plates 1a. Plate 1b, a partition device 2 is provided under the main frame 1, a grinding device 3 is provided on one side of the partition device 2, a transmission device 4 is provided above the grinding device 3, and a mixing box with a feeding port 51 is provided below the transmission device 4 5. The stirring box 5 in the present invention is arranged obliquely above the grinding disc 31. The stirring box 5 can be set as a rectangle or a circle. In order to make the area brushed by the brush 64a larger, the stirring box 5 is preferably set as a circle. Stirring device 6 is arranged in the stirring b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com