Anti-coating reddening and anti-cracking double-core flux-coated electrode for stainless steel welding

A technology of coated electrode and stainless steel, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of decreased mechanical properties of weld seam, poor electrical conductivity, and increased electrode diameter, etc., and achieves less resistance heat, Good corrosion resistance, small volume expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

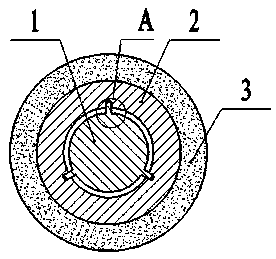

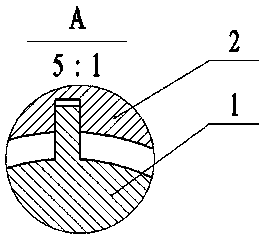

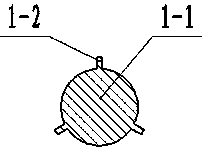

[0027] like Figure 1 to Figure 4 As shown, the double core coated electrode for anti-redness and cracking of the coating for stainless steel welding includes a solid core 1, a hollow core 2 and a coating 3, and the solid core 1 includes a round rod 1- 1 and rib 1-2, the hollow core 2 includes a round tube 2-1 and a groove 2-2, the groove 2-2 is provided on the inner wall of the round tube 2-1, the solid core 1 and the hollow core The welding core 2 is connected with the groove 2-2 through the convex rib 1-2, and the outer surface of the hollow core welding core 2 is covered with the coating 3; the solid core welding core 1 and the hollow core welding core 2 are connected with the concave The fit of the groove 2-2 is an interference fit, and a gap of 0.1mm is reserved between the top of the rib 1-2 and the bottom of the groove 2-2; the diameter of the solid core 1 is smaller than the diameter of the inner circle of the hollow core 2 Smaller than 0.8mm; the number of ribs 1-2 ...

Embodiment 2

[0033] like Figure 1 to Figure 4As shown, the double core coated electrode for anti-redness and cracking of the coating for stainless steel welding includes a solid core 1, a hollow core 2 and a coating 3, and the solid core 1 includes a round rod 1- 1 and ribs 1-2, the hollow core 2 includes a round tube 2-1 and a groove 2-2, the groove 2-2 is provided on the inner wall of the round tube 2-1, the solid core 1 and The hollow core 2 is connected with the groove 2-2 through the convex rib 1-2, and the outer surface of the hollow core 2 is covered with the coating 3; the solid core 1 and the hollow core 2 are connected through the convex rib 1-2 The fit with the groove 2-2 is an interference fit, and a gap of 0.15mm is reserved between the top of the rib 1-2 and the bottom of the groove 2-2; the diameter of the solid core 1 is smaller than that of the hollow core 2. The diameter of the circle is 1.0 mm smaller; the number of convex ribs 1-2 and grooves 2-2 is four.

[0034] Th...

Embodiment 3

[0038] like Figure 1 to Figure 4 As shown, the double core coated electrode for anti-redness and cracking of the coating for stainless steel welding includes a solid core 1, a hollow core 2 and a coating 3, and the solid core 1 includes a round rod 1- 1 and rib 1-2, the hollow core 2 includes a round tube 2-1 and a groove 2-2, the groove 2-2 is provided on the inner wall of the round tube 2-1, the solid core 1 and the hollow core The welding core 2 is connected with the groove 2-2 through the convex rib 1-2, and the outer surface of the hollow core welding core 2 is covered with the coating 3; the solid core welding core 1 and the hollow core welding core 2 are connected with the concave The fit of the groove 2-2 is an interference fit, and a gap of 0.2mm is reserved between the top of the rib 1-2 and the bottom of the groove 2-2; the diameter of the solid core 1 is smaller than the diameter of the inner circle of the hollow core 2 The size is 1.2 mm; the number of convex ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com