Rice husking machine for agricultural machinery

A technology of agricultural machinery and rice milling machine, applied in agriculture, application, grain degerming, etc., can solve the problems of reduced yield, low pressure in the whitening room, verticality error of the whitening roller axis, etc., to achieve uniform whitening, reduce Broken rice, avoid the effect of too little pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

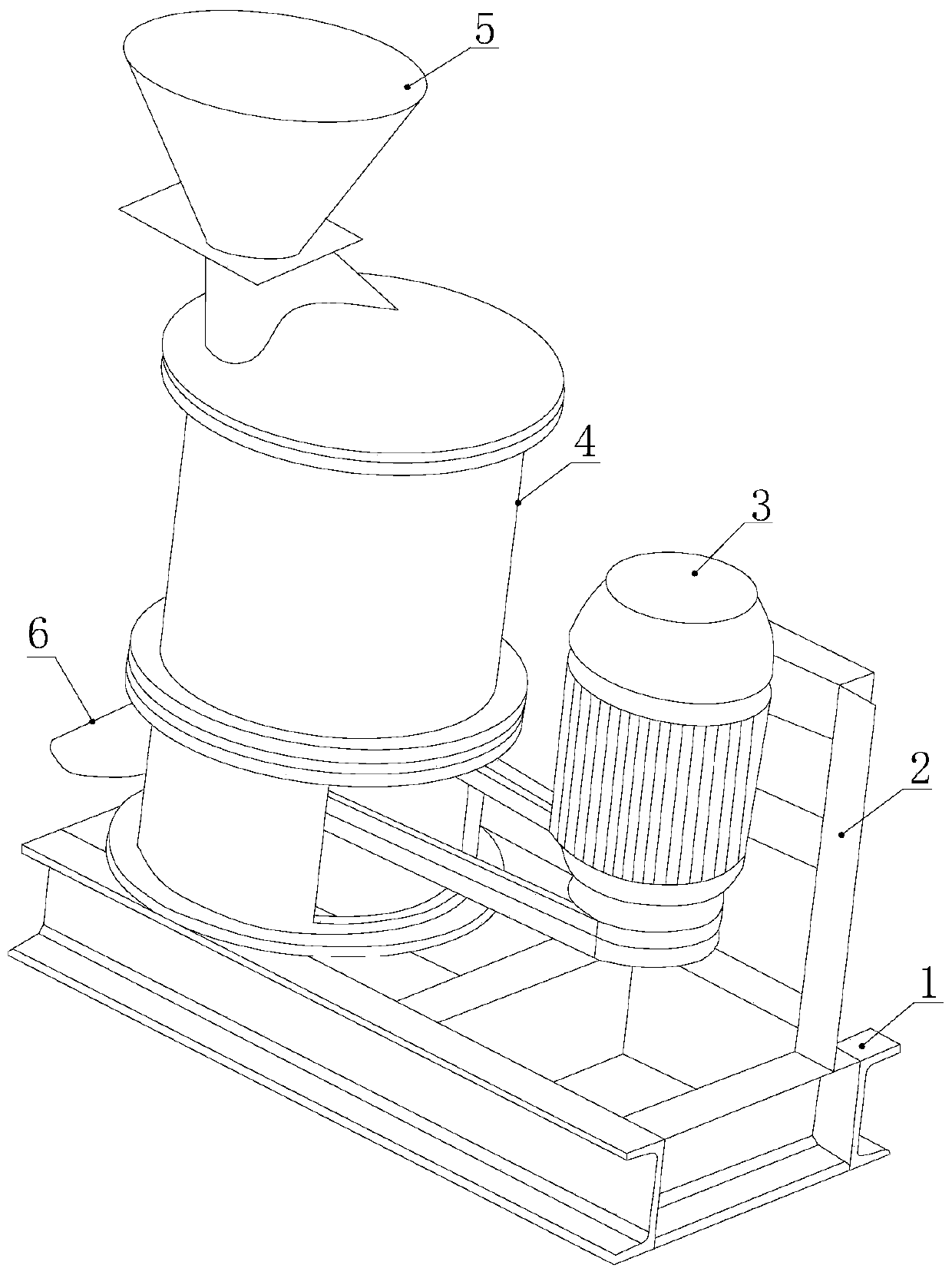

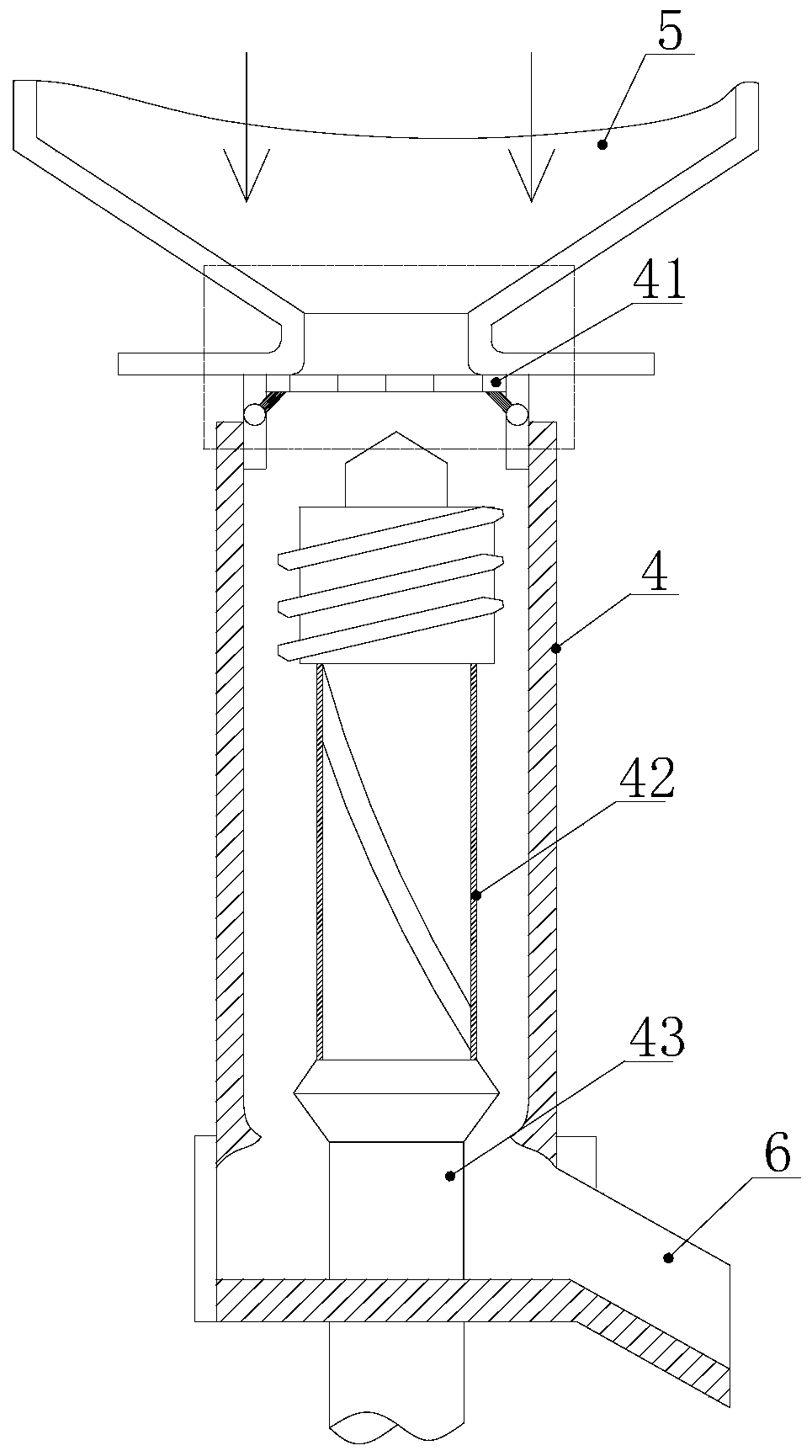

[0029] Such as Figure 1-Figure 3 As shown, the present invention provides a rice mill for agricultural machinery, its structure includes a base 1, a baffle plate 2, a motor 3, a whitening chamber 4, a feed hopper 5, and a discharge port 6, and the base 1 is welded with The baffle plate 2, the baffle plate 2 is used as the outer protective cover of the motor 3, the transmission belt of the motor 3 adopts transmission cooperation with the transmission end of the whitening chamber 4, and the bottom of the whitening chamber 4 is provided with a discharge port 6, in which The adjacent side of the same position of the discharge port 6 is provided with a bran outlet, and a feed hopper 5 is installed on the top of the whitening chamber 4, and a rice sieve 41, a whitening roller 42, a transmission Shaft 43, the rice sieve 41 is located at the interface between the whitening chamber 4 and the feed hopper 5, the rice sieve 41 is fitted on the vertical upper end of the whitening roller 4...

Embodiment 2

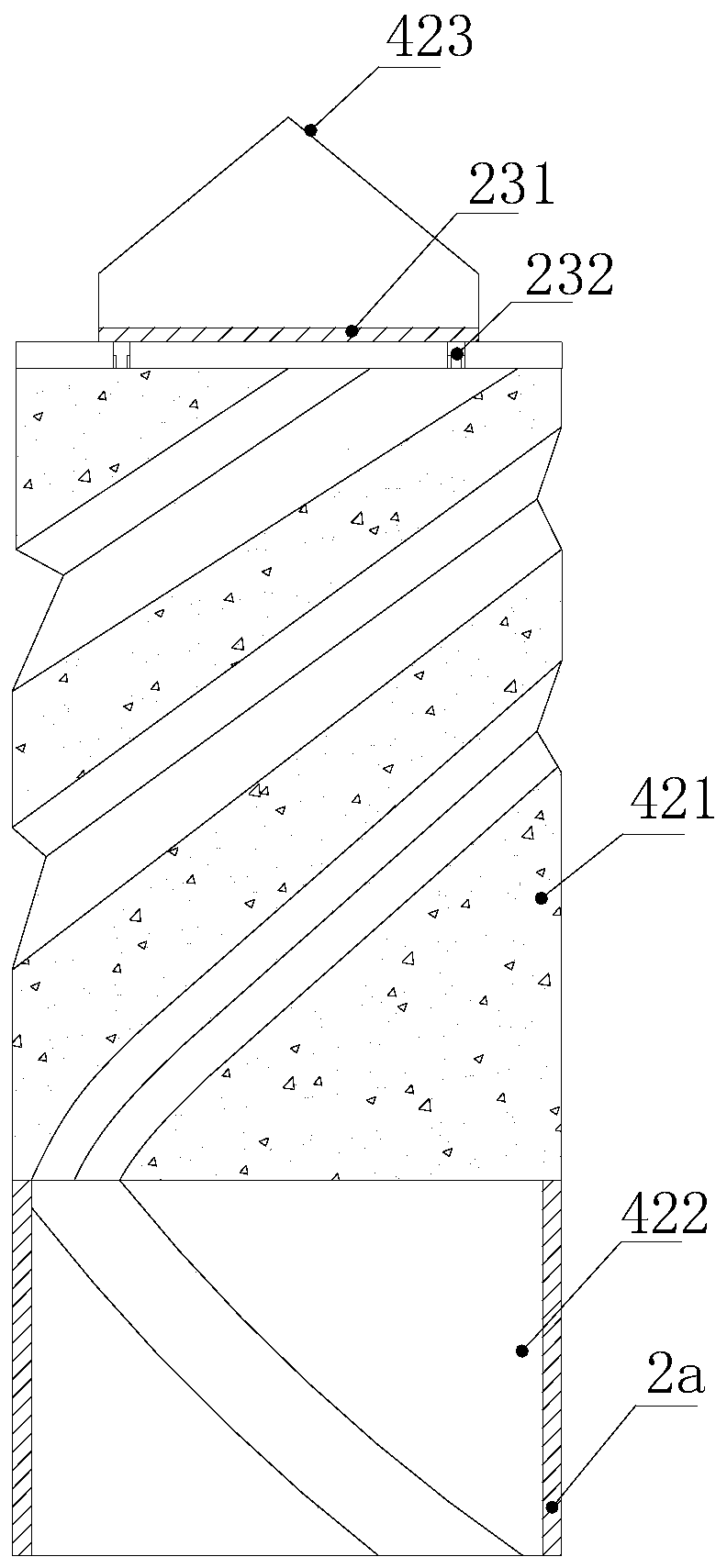

[0033] Such as Figure 4 As shown, the whitening roller 42 is spliced by more than two tile-shaped parts of the same structure, and is divided into upper and lower parts, wherein the upper part has a cutting sheet 421, and the lower part has a friction sheet 422. The cutting sheet The upper end of the 421 is fixed with a conical pressure cap 423, and the friction plate 422 and the cutting plate 421 are fixed with an extension rod 424. The cutting plate 421 is mainly composed of an emery roller, and the friction plate 422 is placed on the surface of the iron roller to realize The effective operation of the cutting sheet 421 and the friction sheet 422, by improving the structure of the whitening roller 42, is spliced with several tile-shaped parts to form upper and lower parts. The upper part is installed as a grinding type, and the lower part is installed as a friction type. The type of whitening roller 42 can be determined according to the original like this, and the press...

Embodiment 3

[0035] Such as Figure 5-Figure 8 As shown, the rice sieve 41 is suspended by the swing rod 411 and the return spring 412, the outer surface of the friction plate 422 is an inner ring a1 in the shape of an abacus, and the inner ring a1 is matched with the outer ring a2. The outer ring a2 is set at the lower end of the rice sieve 41, and is controlled by a return spring 412, and the swinging pull rod 411 is located on the upper top of the return spring 412. The rice sieve 41 is hexagonal and is located in the whitening chamber 4 in a circumferential pressure. There are six gentle changes in the whitening roller 42. At the end of the whitening roller 42 (that is, the position of the friction plate 422), the inner ring a1 in the shape of an abacus is matched with the outer ring a2 controlled by the return spring 412. When the pressure in the whitening chamber When it is not too large, the tension of the return spring 412 moves the rice sieve 41 up, so that there is almost no gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com