Elevator of variable counterweight

A technology for changing counterweights and elevators, which is applied to elevators in buildings, transportation and packaging, etc. It can solve problems such as lifespan, safety and reliability, travel error, inability to change the quality of counterweights, and high transmission power, and achieve good performance. , Novel structure, reduced driving torque and power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

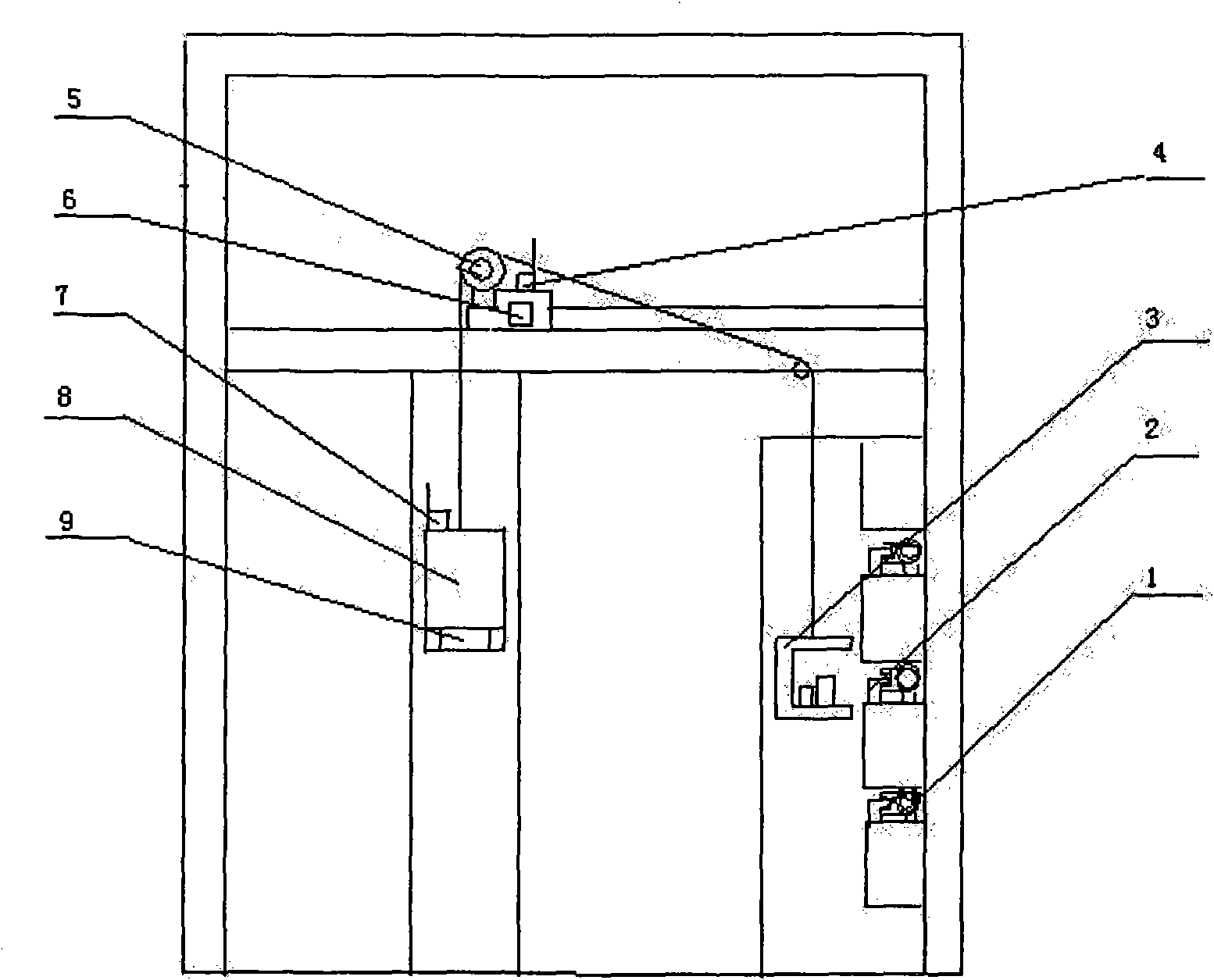

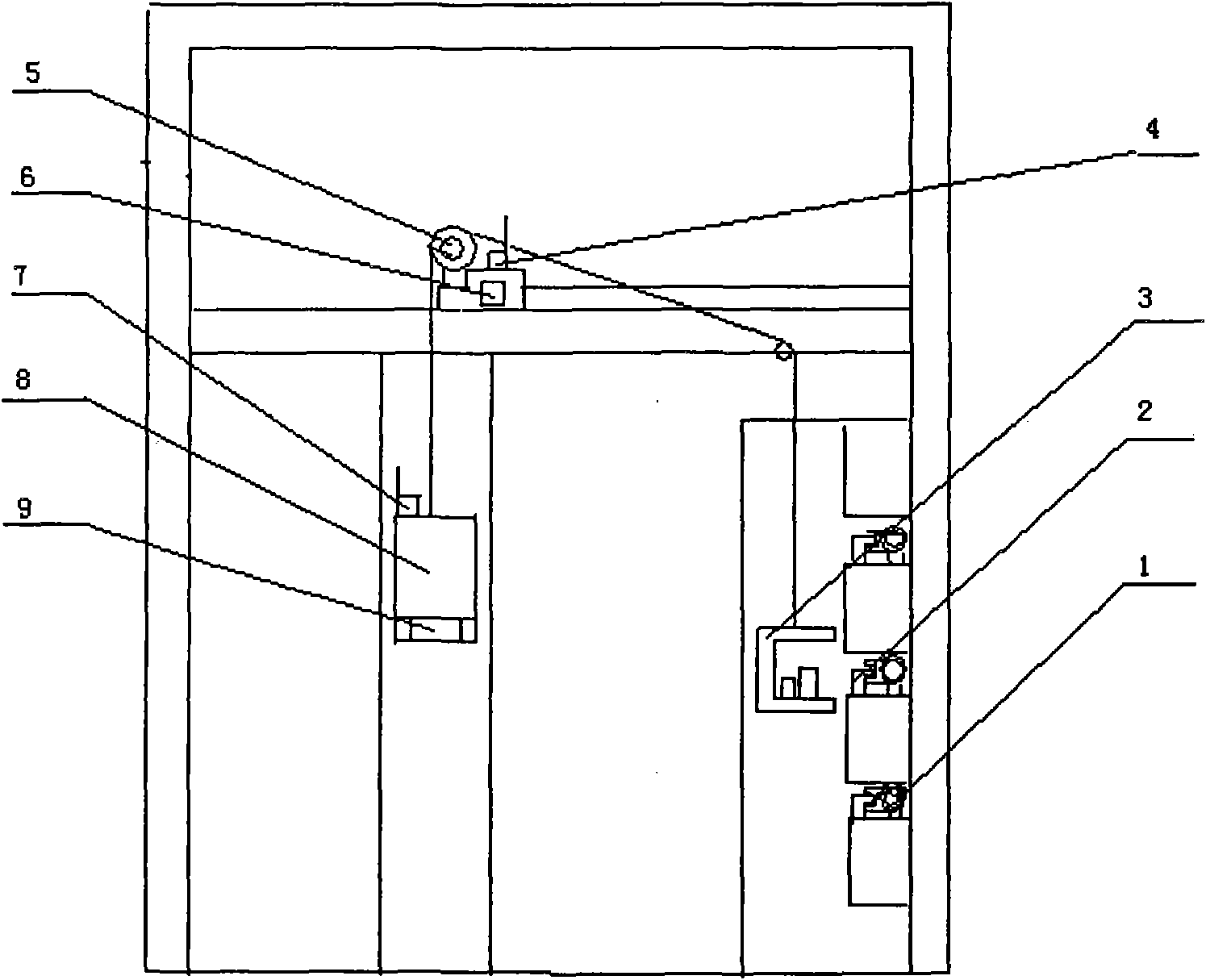

[0010] figure 1 It is a schematic diagram of the structure of the device. The device is equipped with a pressure sensor 9 at the bottom of the car 8. The pressure sensor 9 can generate an induction signal according to the change of the load of the car 8. It is equipped with a wireless transmitter 7, which can transmit its signal through wireless transmission. The device 7 is transmitted to the wireless receiving device 4 of the counterweight control mechanism 6, and the counterweight control mechanism 6 controls the manipulator 1 placed on the corresponding layer on the counterweight side according to the judgment of the signal generation. By moving the mechanical arm and moving the counterweight weight 2, the number of counterweight weights 2 can be increased or decreased to realize the weight change of the variable counterweight car 3 and achieve the balance between the car 8 and the variable counterweight car 3, thereby Realize the up and down movement of the elevator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com