Cable bridge with convenient connection and fireproof function

A cable bridge and bridge technology, applied in the direction of electrical components, etc., can solve the problems of inconvenient cable bridge installation and disassembly, inconvenient cable maintenance, fueling the fire, etc., to achieve the effects of easy laying and replacement, narrowing the scope of fire, and enhancing the effect of fire extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

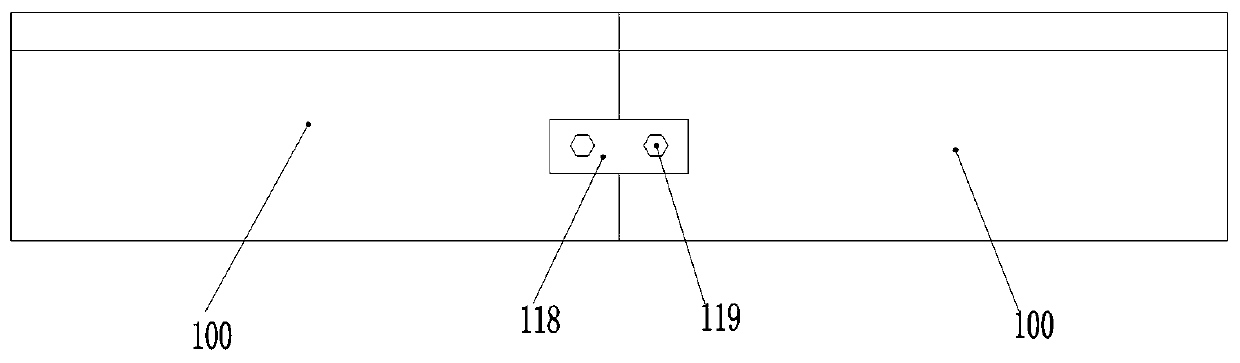

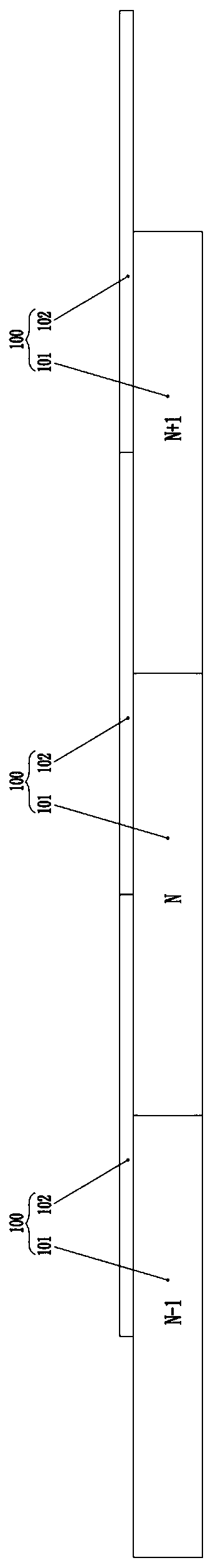

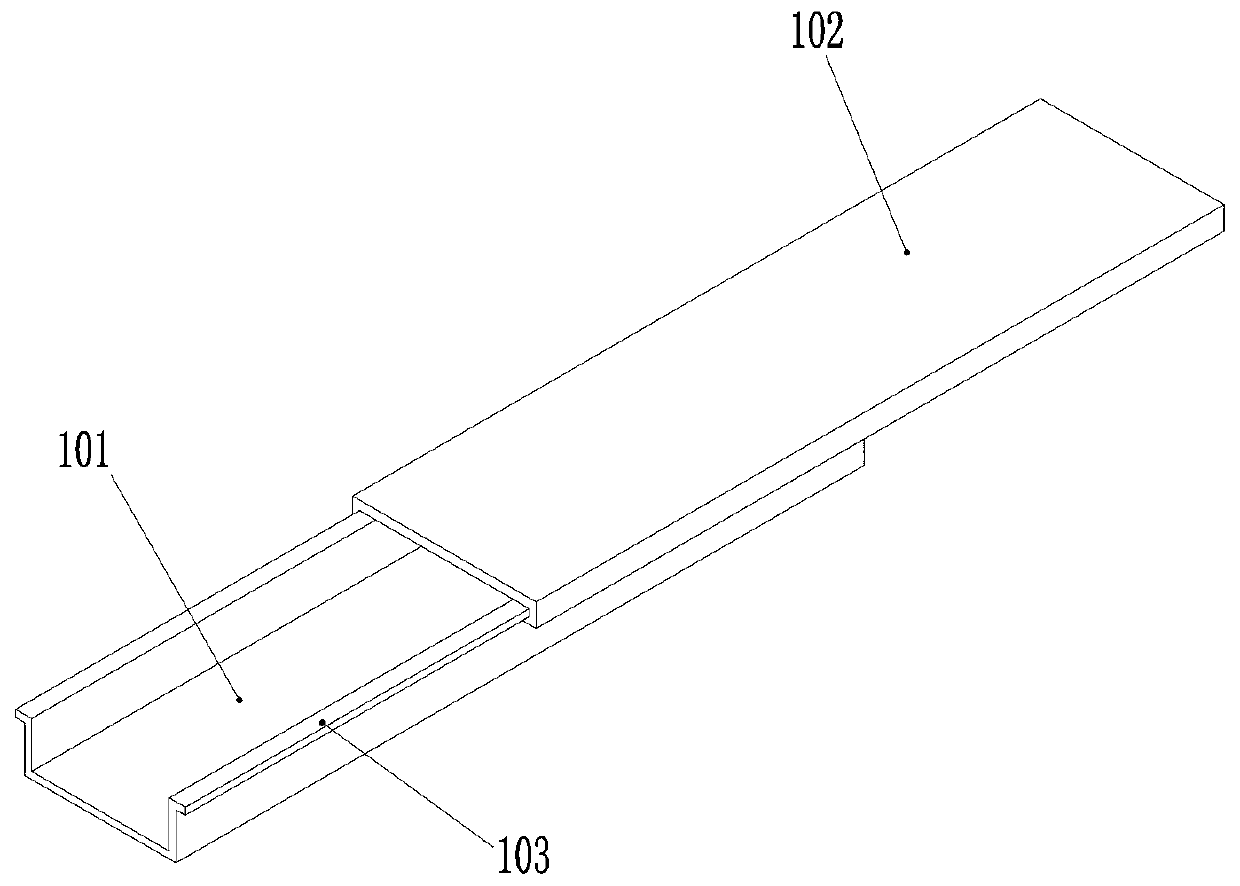

[0030] Example: such as figure 2 , image 3 , Figure 4 As shown, a cable tray with both convenient connection and fire prevention function includes N+1 bridge units 100 connected in sequence, each bridge unit 100 includes a bridge body 101 and a cover plate 102, and the two sides of the bridge body 101 are provided with There are slide rails 103, and slide grooves 104 are provided on both sides of the cover plate 102; the connection mode between two adjacent bridge units 100 is as follows: the cover plate 102 of the Nth bridge unit 100 and the N+1th bridge unit The bridge body 101 of the unit 100 is slidably connected, that is, the right end of the chute 104 on both sides of the N bridge unit 100 is slidably connected with the left end of the slide rail 103 on both sides of the N+1 bridge unit 100; the N bridge unit The bridge body 101 of 100 is slidingly connected with the cover plates 102 of N-1 bridge units 100, that is, the left end of the slide rail 103 on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com