Wafer Cassette Rotating Device and Cassette Rotary Lifting Equipment

A technology for rotating devices and wafers, which is applied in sustainable manufacturing/processing, climate sustainability, and final product manufacturing. It can solve problems such as uneven corrosion thickness and low corrosion efficiency, reduce concentration differences, and improve Corrosion efficiency, the effect of alleviating the unevenness of corrosion thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

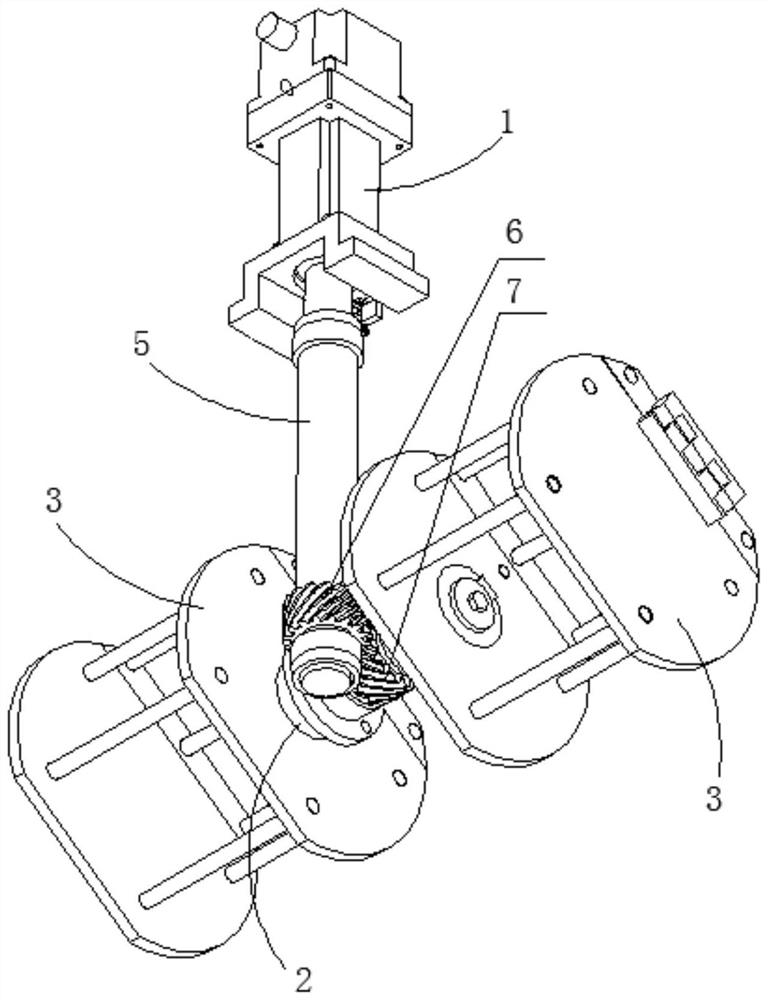

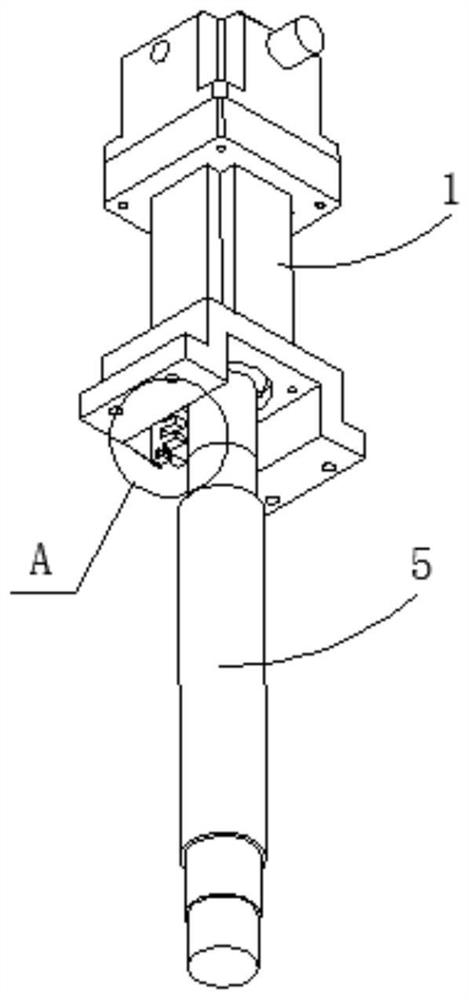

[0039] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0051] Referring to Figure 5 and Figure 6, in the specific structure of the film box basket 3 can be provided with a basket body 31 and a cover 32, the basket of this

[0057] Preferably, the motor can be set as a servo motor to respond to the control command of the controller in time.

[0058] Specifically, referring to FIG. 6, the basket body 31 is mainly composed of two side plates 311 and a number of first support rods 312, and two

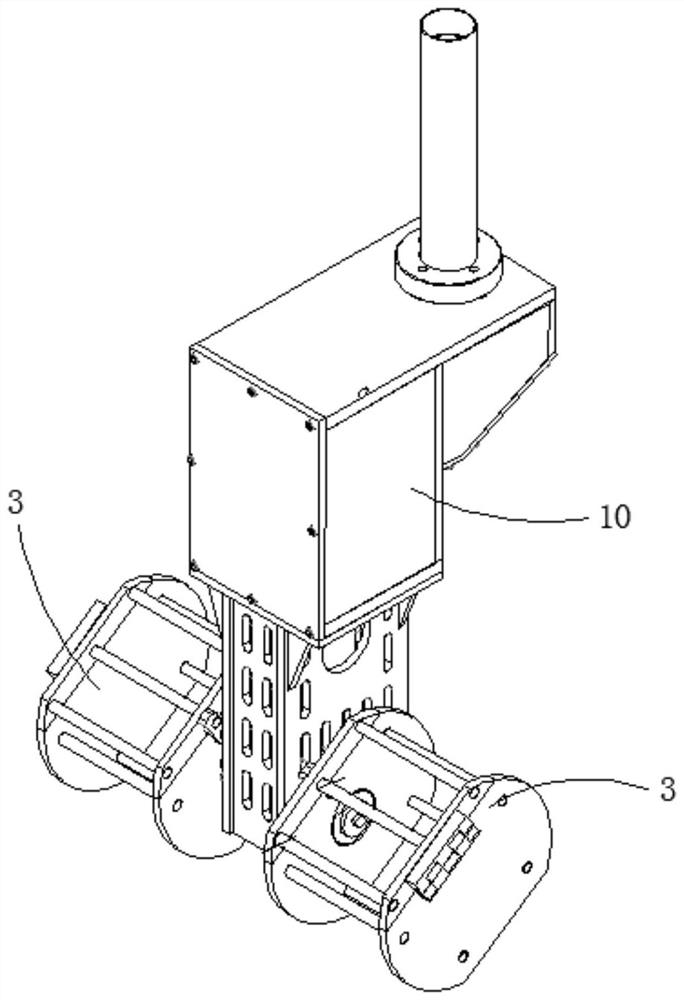

[0059] Preferably, referring to FIG. 1, a casing can be set on the outside of the driver 1, the connecting rod shaft 2, the first gear 6 and the second gear 7

[0063] To sum up, the embodiment of the present invention discloses a wafer cassette rotating device and a cassette rotating lifting device, which

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com