Cold smoke recirculating unit heat conduction oil recovery bypass smoke heat system and control method

A heat system and recycling technology, applied in preheating, feed water heaters, climate sustainability, etc., can solve the problems of affecting fuel burn, unreasonable recovery, complex automatic control operation, etc., to reduce the design pressure level, Reduced initial investment and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

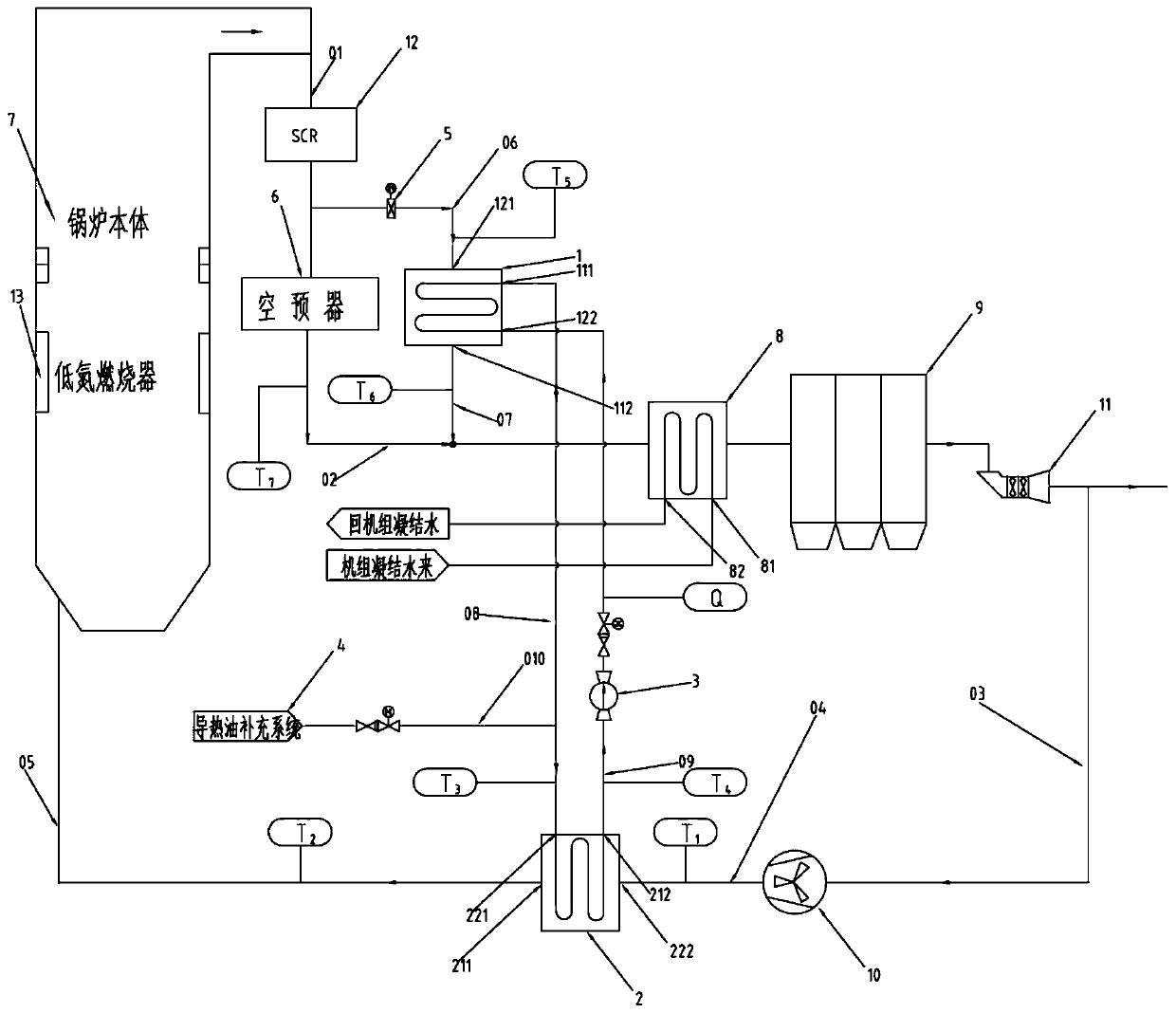

[0047] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0048] The following explains the proper nouns that appear in the following technical solutions: cold smoke: refers to the flue gas behind the dust collector or induced draft fan, taking a large coal-fired unit equipped with a low-temperature electrostatic precipitator as an example, the flue gas passes through the dust collector or After the induced draft fan, the dust concentration is less than 100mg / Nm 3 , the temperature is about 70 ~ 150 ℃. Cold smoke recircu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com