Engine cooling fan control system

A technology for engine cooling and fan control, which is applied in the direction of engine cooling, coolant flow control, engine components, etc. It can solve the problems of slow response, slow speed, and slow flow of silicone oil fans, etc., to achieve lower water temperature, quick response, The effect of increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

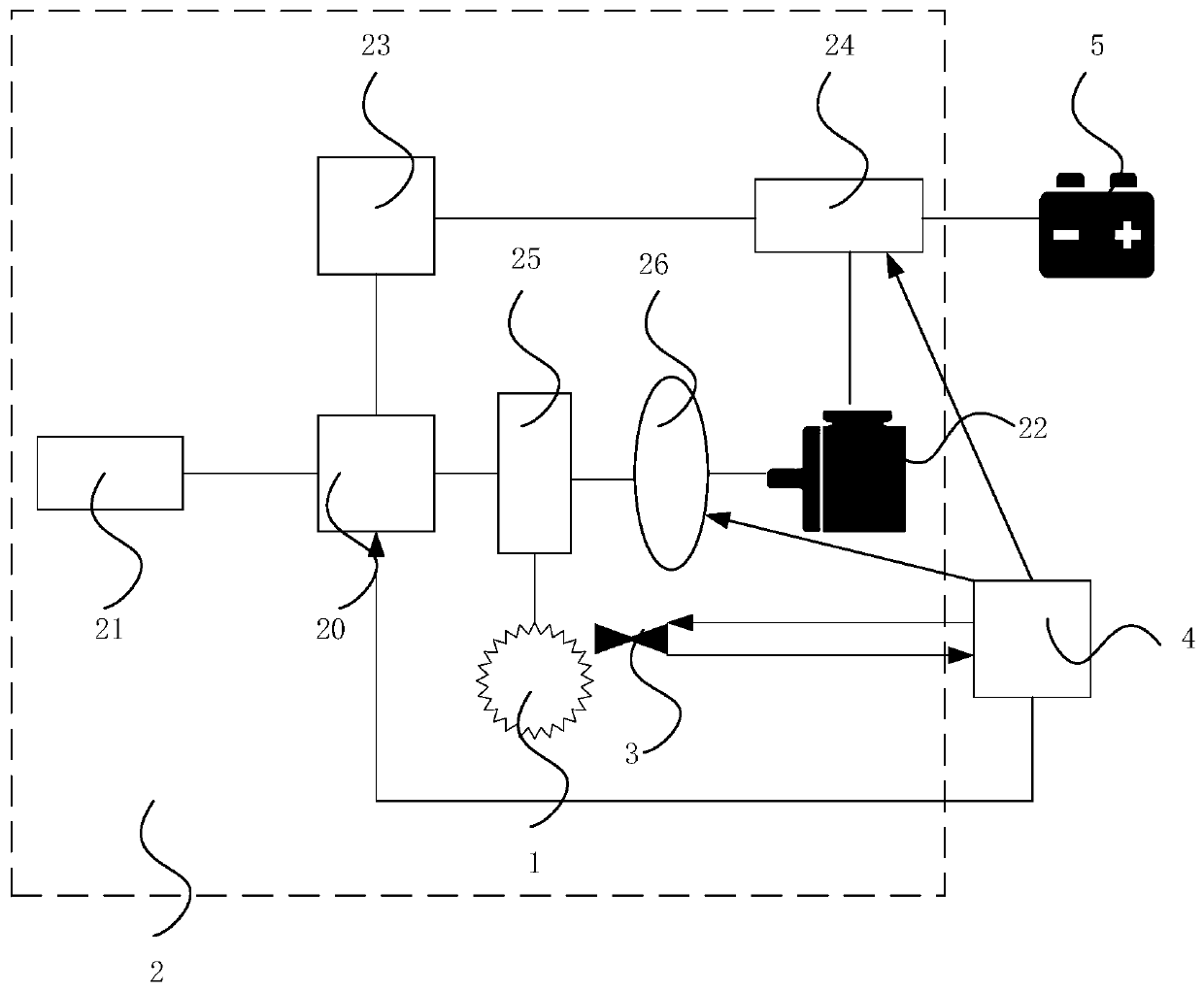

[0031] see figure 1 As shown, the embodiment of the present invention provides an engine cooling fan control system, which includes a silicon oil fan 1, a power system 2, a fan sensor 3 and a controller 4; The controller 4 is newly added, and the electronic control unit ECU has been connected with the engine 21, so the arrangement and connection of lines are reduced. The threshold value of the speed of the silicone oil fan 1 is calibrated in advance. When the engine water temperature is 90°C, the speed of the silicone oil fan 1 is set as the threshold value, so that the engine water temperature is kept at 90°C, preventing the engine from being too low and insufficient in power, and too high from affecting engine performance. The power system 2 includes a power splitter 20, an engine 21 and an electric motor 22 connected to the power splitter 20. In the embodiment of the present invention, by adding the electric motor 22, the water temperature of the engine can be satisfied whe...

Embodiment 2

[0035] The basic content of embodiment 2 of the present invention is the same as embodiment 1, and difference is:

[0036]The power system 2 of Embodiment 2 of the present invention further includes a generator 23 , which is connected to the power splitter 20 and the motor 22 , and is used to convert the power of the engine 21 into electric power and distribute it to the motor 22 . When the speed of the silicone oil fan 1 is lower than the threshold, the controller 4 distributes the power of the engine 21 to the generator 23 by controlling the power splitter 20, and the generator 23 converts the power into electricity, and transmits the electricity to the motor 22, and the motor 22 Electricity is converted into power to drive the silicon oil fan 1 to rotate rapidly.

Embodiment 3

[0038] The basic content of embodiment 3 of the present invention is the same as embodiment 2, and difference is:

[0039] The control system also includes a storage battery 5, which is connected to the generator 23. When the speed of the silicon oil fan 1 is lower than the threshold, the controller 4 distributes the power of the engine 21 to the generator 23 by controlling the power splitter 20. 23 converts the power into electricity, and transmits part of the electricity to the motor 22. The motor 22 converts the electricity into power to drive the silicon oil fan 1 to rotate quickly, and the remaining part is transmitted to the battery 5 to charge the battery 5. The battery 5 is used for During the operation of the vehicle, it supplies power to the electrical components of the vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com