Pneumatic concrete wet spraying machine

A wet blasting machine and concrete technology, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of material jamming, pneumatic device pressure gas pressure reduction, large impact material head, etc., to improve the continuity and stability, Reduce the required space and ensure the effect of the shotcrete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

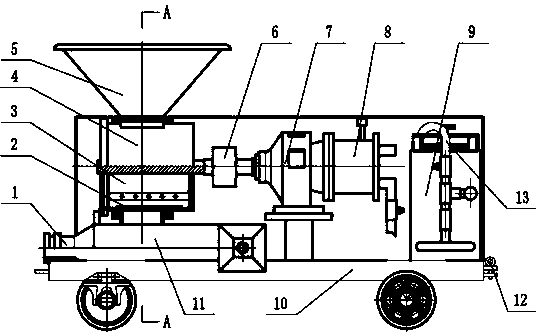

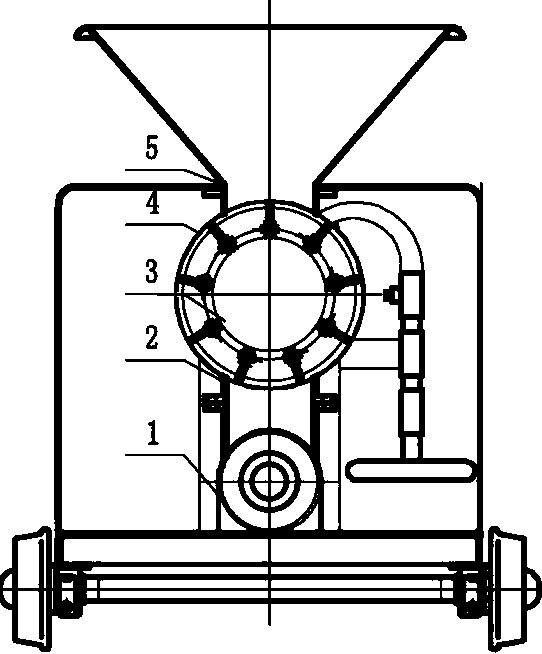

[0017] Such as figure 1 and figure 2 As shown, a pneumatic concrete wet spraying machine includes a chassis 10, a grout mixing and spraying device arranged at the front of the chassis 10, a power unit arranged at the middle of the chassis 10 and an accelerator tank 9 arranged at the rear of the chassis 10, The tail end of the chassis 10 is provided with a connecting pin 12; the mixing and spraying device includes a hopper 5 arranged on the top, a mixing bucket 4 communicated with the bottom of the hopper 5, a rotor 3 arranged in the mixing bucket 4, The sealing plate 2 arranged at the bottom outlet of the mixing tank 4, the material storage chamber 11 communicated with the bottom outlet of the mixing tank 4 and the nozzle 1 arranged at the front end of the material storage room 11; The reducer 7, the pneumatic fan 8 installed on the input shaft side of the reducer 7 and the coupling 6 installed on the output shaft side of the reducer 7, the coupling 6 and the rotor 3 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com