Novel threaded joint sealing material

A sealing material, a new type of technology, applied in the direction of textiles and papermaking, other chemical processes, chemical instruments and methods, etc., can solve the problems of easy assembly and difficult disassembly, toxic and harmful substances, time-consuming and labor-consuming, etc., to achieve stable structural strength, anti-corrosion Strong tearing ability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

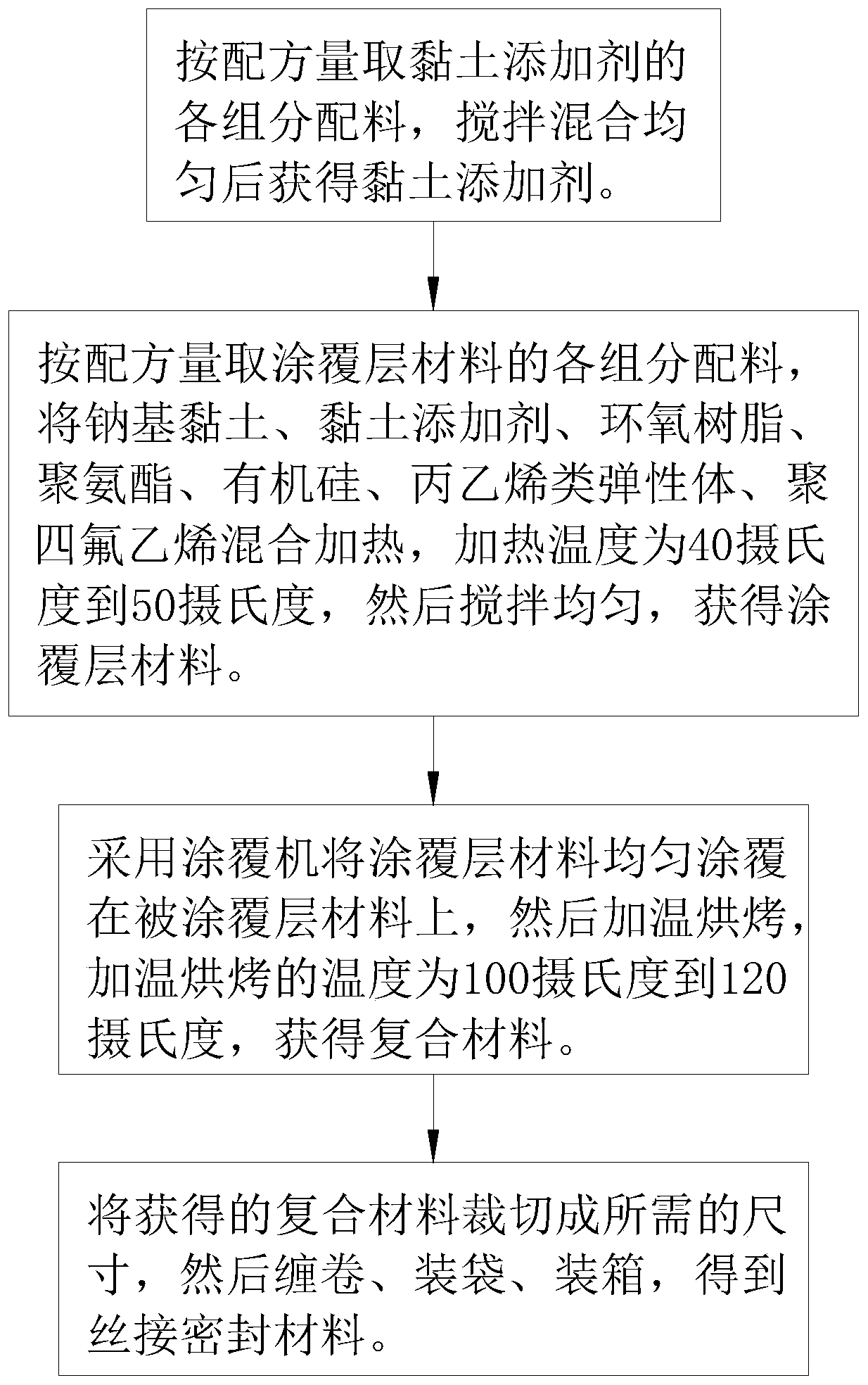

Image

Examples

Embodiment 1

[0023] This embodiment provides a technical solution: a new type of wire joint sealing material, the sealing material includes a coating layer material and a coated layer material that are composited with each other.

[0024] Coating layer materials include by weight: 45 parts of sodium-based clay, 5 parts of clay additives, 15 parts of epoxy resin, 7 parts of polyurethane, 5 parts of silicone, 5 parts of propylene elastomer, polytetrafluoroethylene Ethylene 13 parts. The material of the coated layer is non-woven fabric, and the material of the coated layer is uniformly coated on the surface of the material of the coated layer and forms a double-layer composite structure with the material of the coated layer.

[0025] Wherein, based on 100 parts by weight of the clay additive, the clay additive includes by weight: 18 parts of polyacrylamide, 12 parts of potassium aluminum sulfate, 70 parts of calcium magnesium chloride, and 10 parts of sodium fluorosilicate.

[0026] Sodium-b...

Embodiment 2

[0041] This embodiment provides a technical solution: a new type of wire joint sealing material, the sealing material includes a coating layer material and a coated layer material that are composited with each other.

[0042] Coating layer materials include by weight: 40 parts of sodium-based clay, 5 parts of clay additives, 15 parts of epoxy resin, 7 parts of polyurethane, 5 parts of silicone, 8 parts of propylene elastomer, polytetrafluoroethylene 15 parts of vinyl. The material of the coated layer is non-woven fabric, and the material of the coated layer is uniformly coated on the surface of the material of the coated layer and forms a double-layer composite structure with the material of the coated layer.

[0043] Wherein, based on 100 parts by weight of the clay additive, the clay additive includes by weight: 18 parts of polyacrylamide, 12 parts of potassium aluminum sulfate, 70 parts of calcium magnesium chloride, and 10 parts of sodium fluorosilicate.

[0044] Then pre...

Embodiment 3

[0049] This embodiment provides a technical solution: a new type of wire joint sealing material, the sealing material includes a coating layer material and a coated layer material that are composited with each other.

[0050] Coating layer materials include by weight: 60 parts of sodium-based clay, 2 parts of clay additives, 10 parts of epoxy resin, 5 parts of polyurethane, 5 parts of silicone, 5 parts of propylene elastomer, polytetrafluoroethylene Ethylene 12 parts. The material of the coated layer is non-woven fabric, and the material of the coated layer is uniformly coated on the surface of the material of the coated layer and forms a double-layer composite structure with the material of the coated layer.

[0051] Wherein, based on 100 parts by weight of the clay additive, the clay additive includes by weight: 18 parts of polyacrylamide, 12 parts of potassium aluminum sulfate, 70 parts of calcium magnesium chloride, and 10 parts of sodium fluorosilicate.

[0052] Then pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com