Fabric pull-down devices for computerized flat knitting machine

A computerized flat knitting and fabric technology, applied in the directions of knitting, weft knitting, textiles and papermaking, can solve the problems of unstable tension and uneven tension, and achieve the effect of high fabric quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

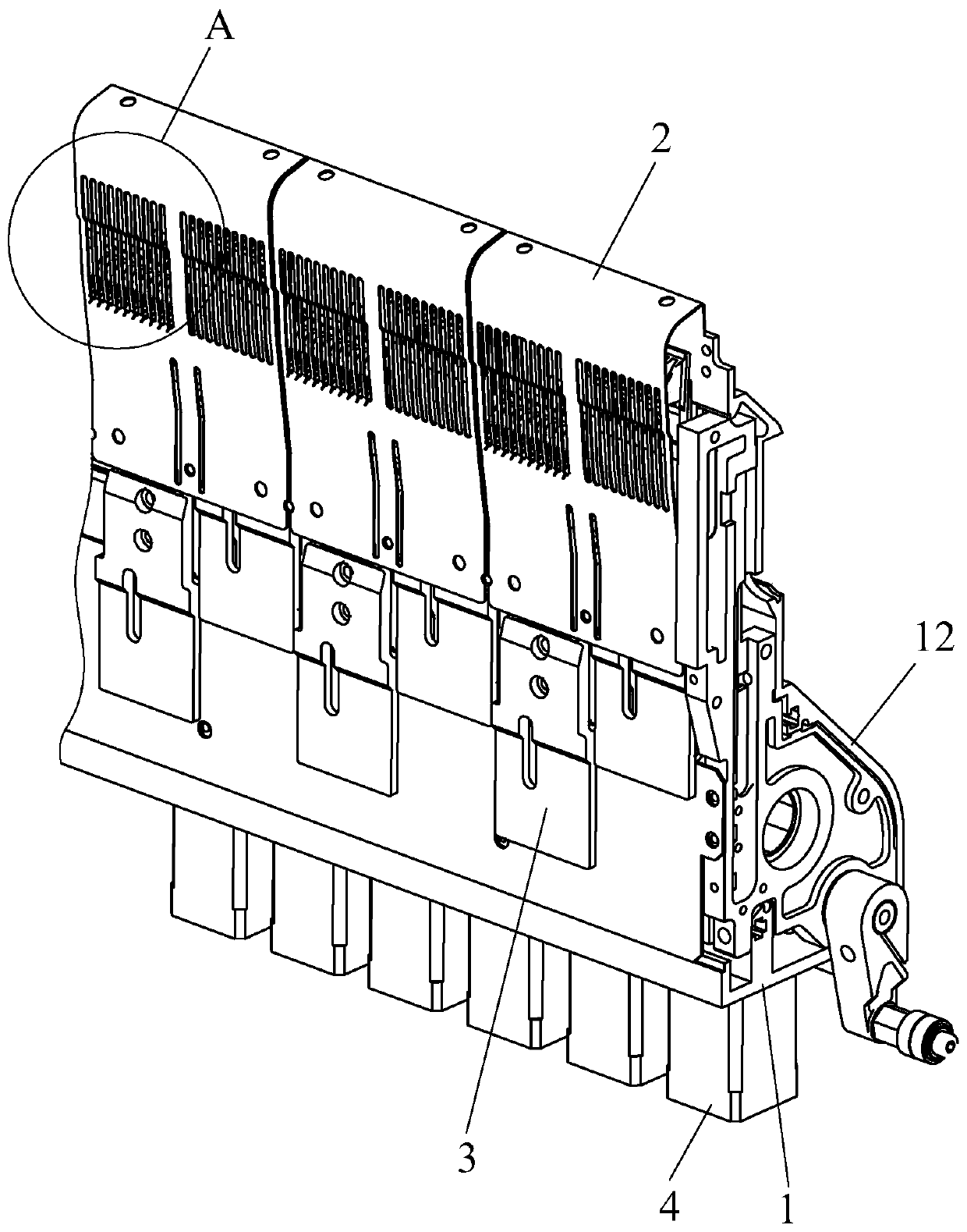

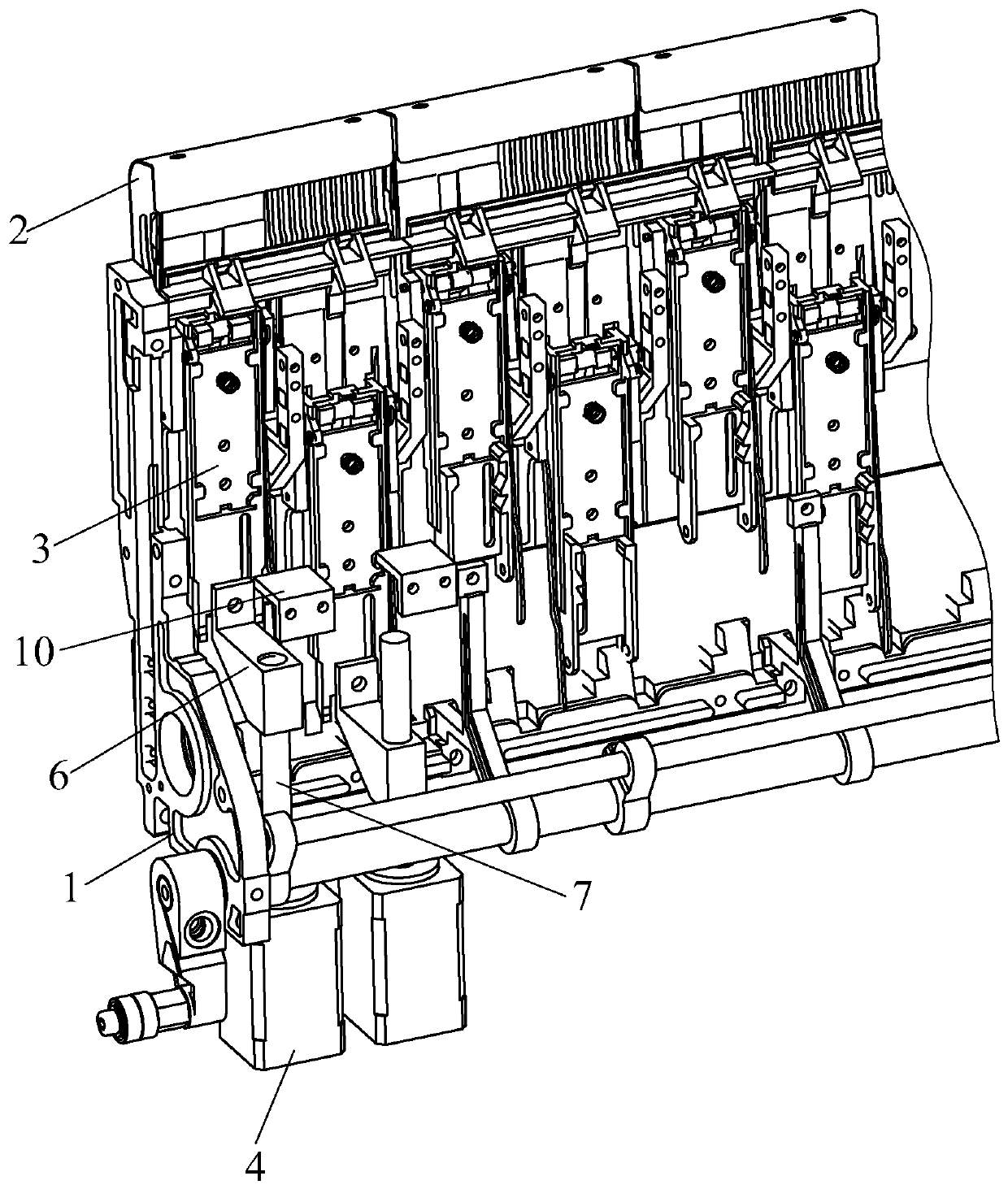

[0030] see Figure 1 to Figure 7 .

[0031] This embodiment discloses a fabric pull-down device for computerized flat knitting machines, which are arranged in pairs under the front and rear needle beds of the flat knitting machine. The fabric pull-down device includes a base 1, an upper shield 2, several Catch pawl 3 and be used to drive the drive motor 4 that catches paw 3 to move up and down, and drive motor 4 adopts servo motor.

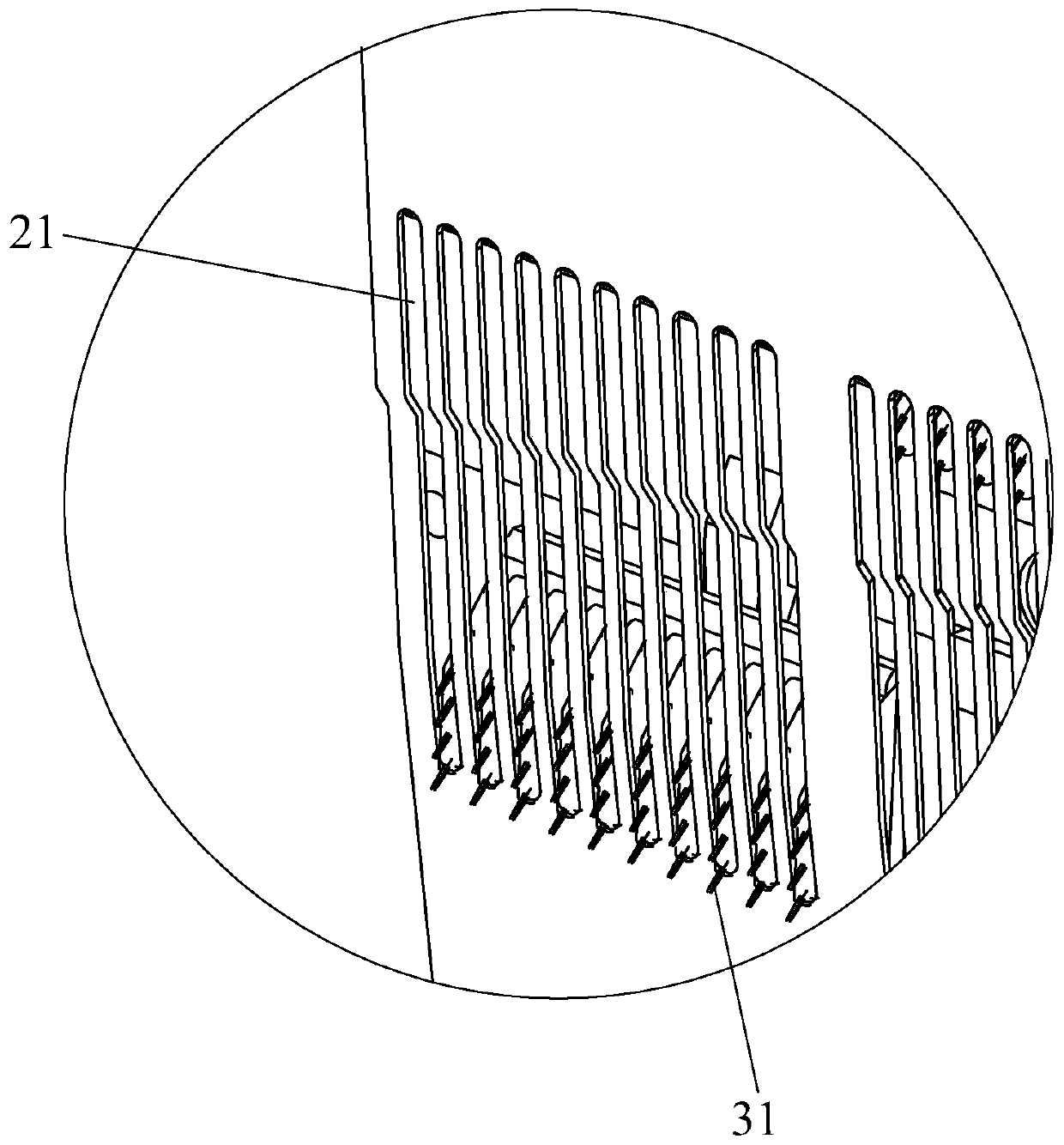

[0032] In this embodiment, the catch claw 3 is provided with a needle 31 for hooking the fabric, and the base 1 is fixedly installed on the flat knitting machine. The upper shield 2 is installed above the base 1, and its front side is provided with a slot 21 that can expose the needle 31 on the catch claw 3.

[0033] In this embodiment, a catch claw 3 is equipped with a drive motor 4, and the drive motor 4 is installed on the base 1. When the drive motor 4 drives the catch claw 3 to descend, the catch claw 3 approaches the front side of the uppe...

Embodiment 2

[0040] refer to Figure 8 to Figure 10, the difference between the present embodiment 2 and the embodiment 1 is: a push rod 9 is equipped with a push rod electromagnet 11, and the push rod electromagnet 11 is installed on the base 1, and it acts on the tail of the rise rod 9 to catch the paw 3 When rising to a certain height, the push rod of the push rod electromagnet 11 stretches out against the tail of the warping rod 9, so that the tail of the warping rod 9 moves toward the front side of the upper shield 2, that is, drives the catch claw 3 Turn away from the direction of the front side of the upper shield 2, so that the catch claws 3 are completely in the upper shield 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com