Whole-sizing and wearing preparation method of washable towel fabric

A washing-resistant, hand-towel technology, applied in textile and papermaking, textile, fabric and other directions, to achieve the effect of good abrasion resistance, less hairiness, and reduced ruffles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

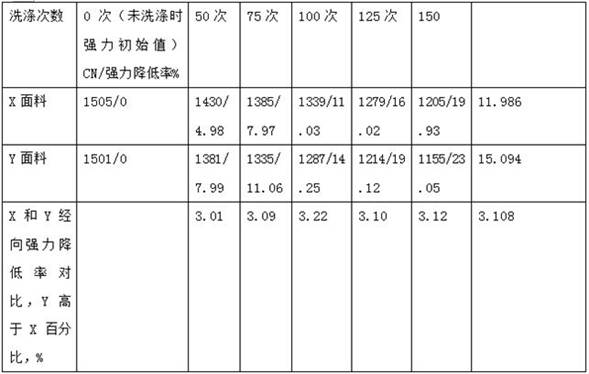

Examples

Embodiment 1

[0041] 8. The speed of the arranger is 600m / min. The tube is high -speed to retreat. It requires a stable speed. It is required that the tube is better formed, the size is uniform, and the row is uniform.The teeth are more sparsely scalable 筘 to ensure that the meridians are arranged uniformly, and the guidance yarn is evenly distributed on the tone shaft. At the same time, it cannot be pressed to ensure that the gauze is retreated smoothly.

[0042] 9. The pressure roller pressure during the arranger is 0.32 MPA, the main shaft braking pressure is 0.1-0.2MPa, the right top tight pressure is 0.3-0.4 mPa, and the pressure roller braking pressure is 0.2-0.3 mPa.The hardness of the ar over (Shaw's hardness) hardness is 65.

[0043] 10. The density of the axis yarn is 0.027g / cm³.

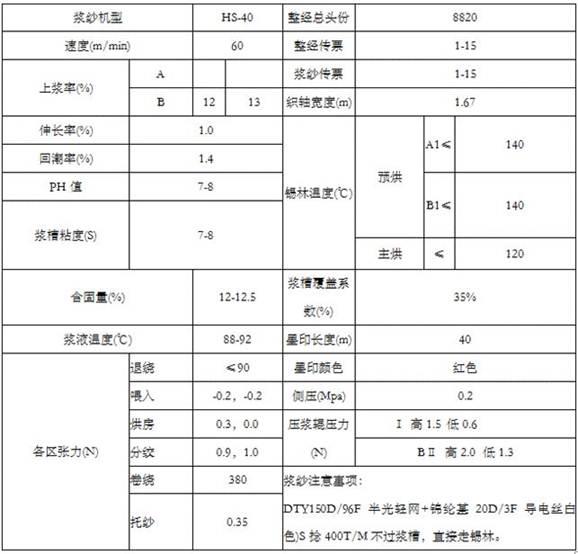

[0044] Second, the gauze: The slurry yarn uses the Jin Tianju HS-40 double slurry gauze veil.

[0045] 1. The slurry formula is as follows:

[0046] 2. The yarn is a vortex spinning yarn. After detecting th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com