A purely pneumatic folding-in device for short raw edges of a shuttleless loom

A technology of tuck-in edge device and shuttleless loom, which is applied in looms, textiles, textiles and papermaking, etc. It can solve the problems of unstable mechanical parts, affecting production efficiency, and long burr length, so as to improve production efficiency and fabric High quality, high performance-price ratio, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

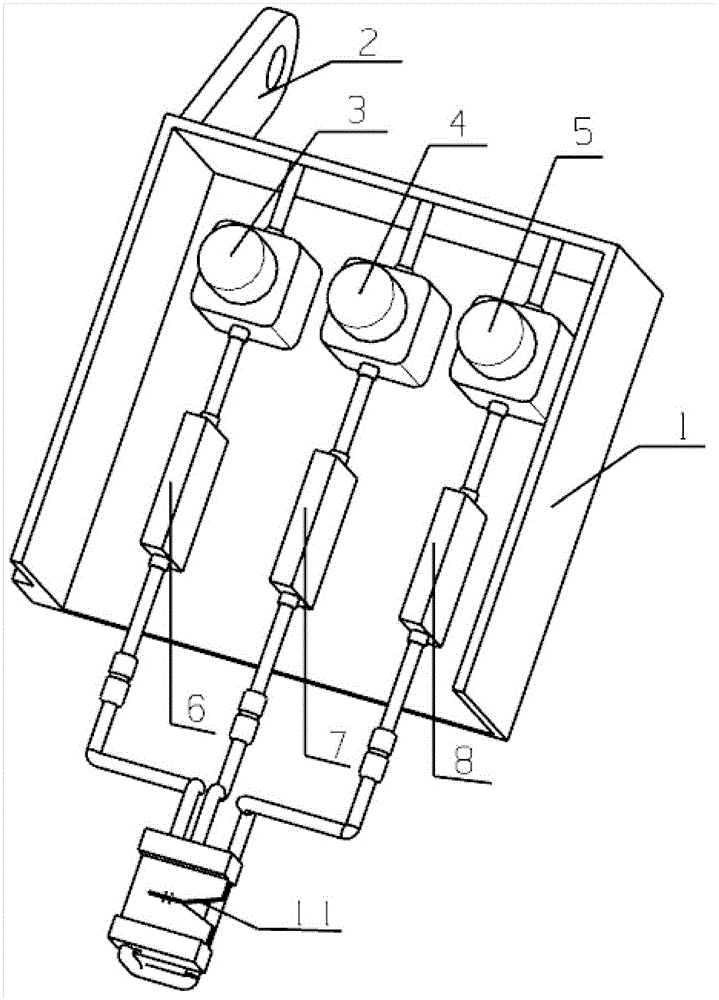

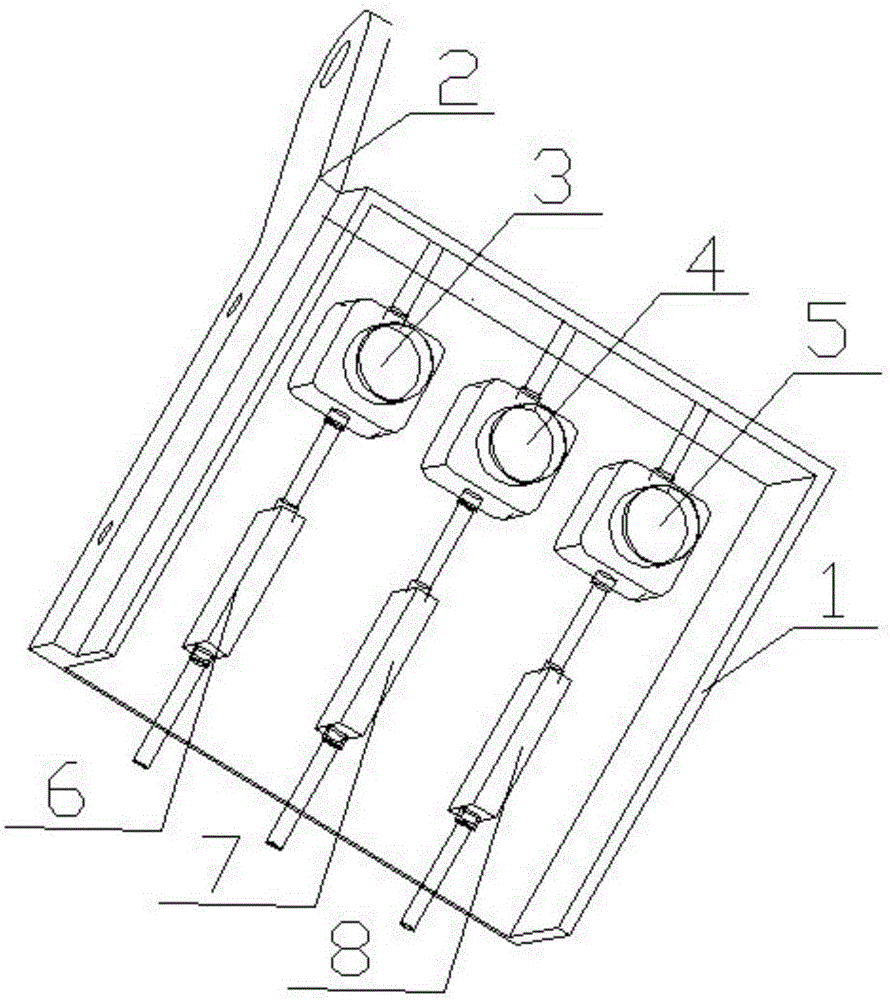

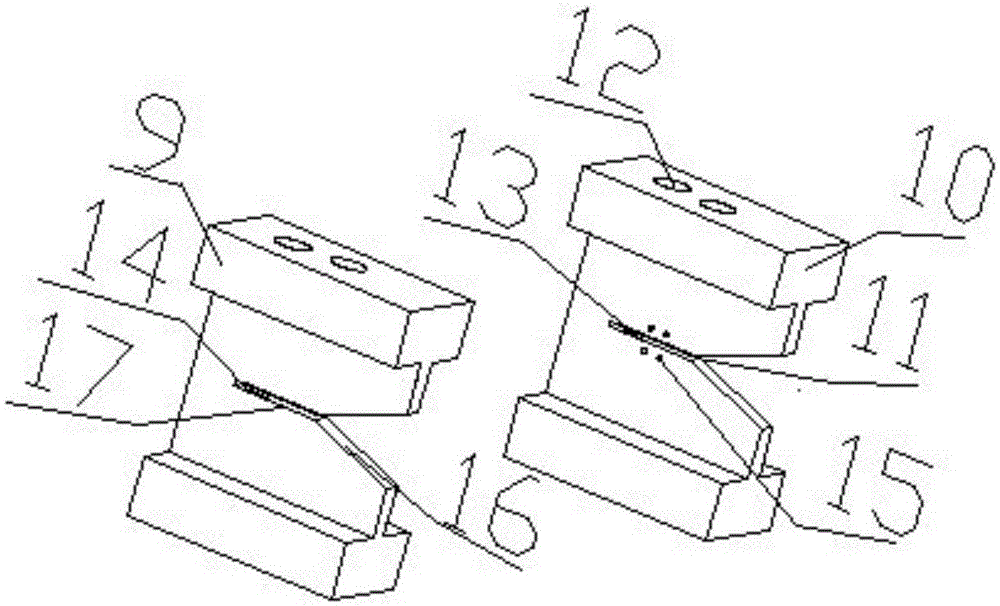

[0012] A kind of pure pneumatic folding-in device for the short raw edge of the shuttleless loom in this embodiment, such as Figure 1-3 As shown, it includes a symmetrically arranged left purely pneumatic fold-in device 9, a right purely pneumatic fold-in device 10, and two control boxes 1, and one of the two control boxes 1 is connected with the left purely pneumatic fold-in device through a pipeline. The edge entering device 9 is connected, and the other is connected with the right pure pneumatic folding device 10 through a pipeline. The left pure pneumatic folding device 9 and the right pure pneumatic folding device 10 are respectively installed on the shuttleless loom close to On the frame on both sides of the weaving fell; the left pure pneumatic folding device 9 and the right pure pneumatic folding device 10 are respectively provided with a Y-shaped yarn guide port 11 and a round yarn end Holding through hole 12, 1 lower yarn end rectangular narrow and long holding thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com