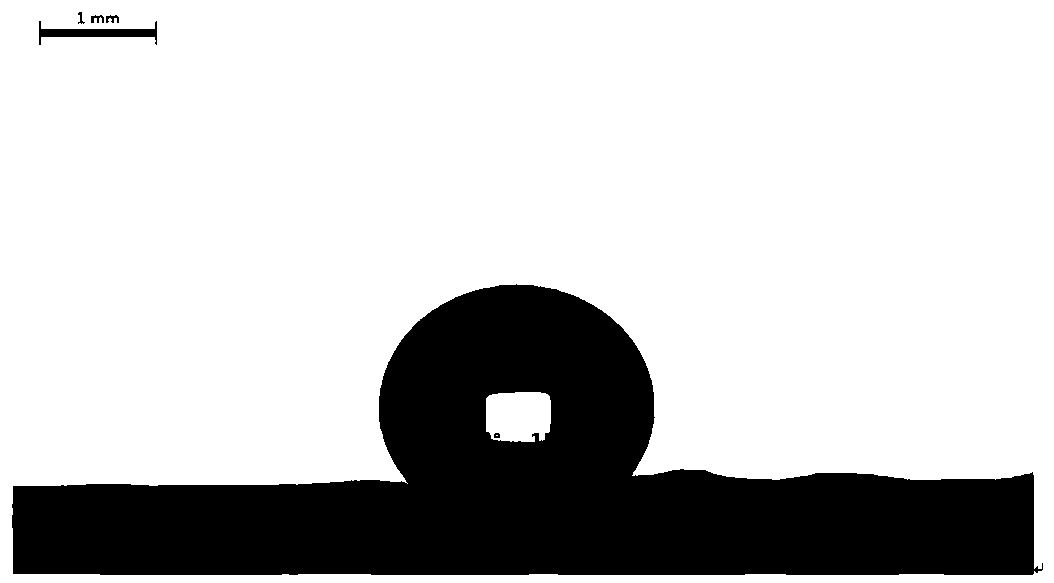

Preparation method of nano SiO2 modified epoxy resin super-hydrophobic coating material

A super-hydrophobic coating, epoxy resin technology, applied in epoxy resin coatings, coatings and other directions, can solve problems such as limiting the use of epoxy resin coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

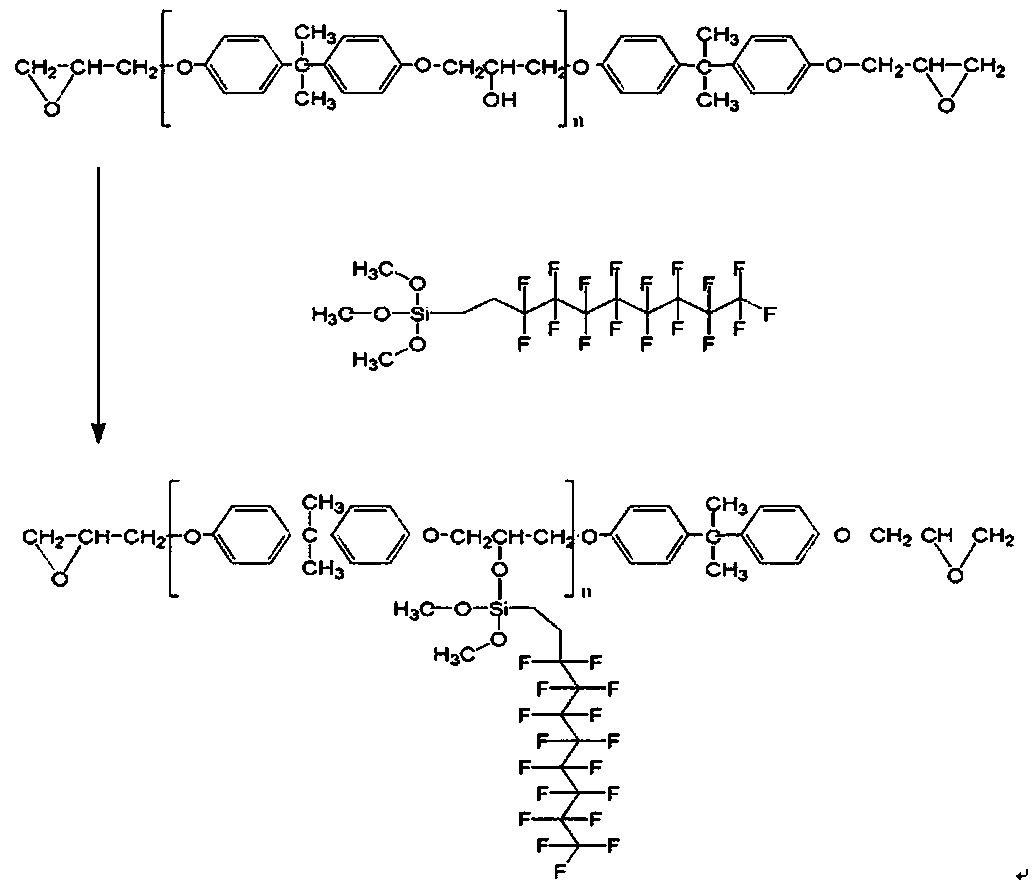

[0025] Weigh 2.0121g of EP CYD-127 epoxy resin, then add 1.73g of trimethoxy (1H,1H,2H,2H-heptadecafluorodecyl) silane dropwise, and then add the prepared absolute ethanol: water 20ml of ethanol aqueous solution with a volume ratio of 9:1, ultrasonically dispersed for 20 minutes, condensed and refluxed in an oil bath at 65°C for 5 hours. Then, the modified epoxy resin solution that has been reacted is evaporated to dryness with a rotary evaporator, and finally centrifuged to obtain the modified epoxy resin;

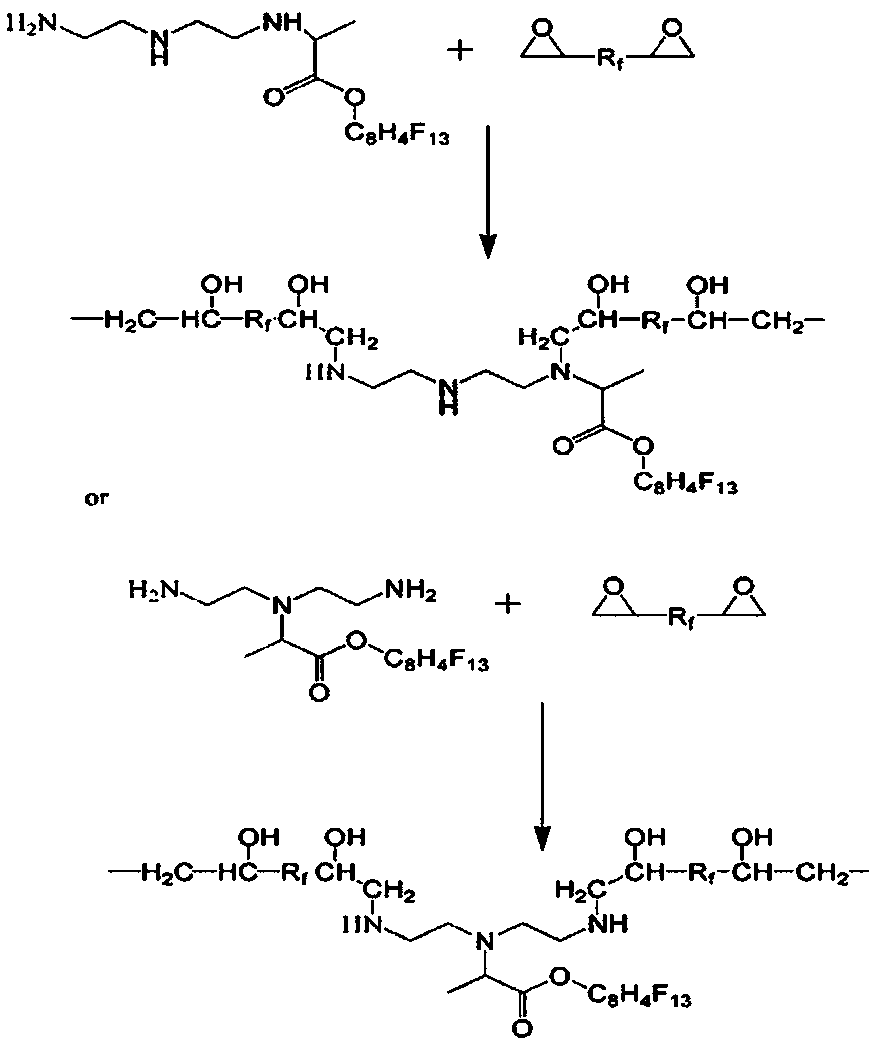

[0026] Weigh 5.66g of diethylenetriamine, 1.5g of sodium ethoxide, and 50ml of absolute ethanol. First, ultrasonically disperse for 15 minutes, then stir in an oil bath under nitrogen protection for 1 hour, set the temperature to 70°C, and then add 11g of methyl Tridecafluorooctyl acrylate continued to react for 23 hours, the crude product was rotary evaporated to remove the solvent, added deionized water to wash until neutral, and then filtered to obtain a modified curin...

Embodiment 2

[0029] Weigh 3 g of EP CYD-127 type epoxy resin, then add 1.23 g of trimethoxy (1H, 1H, 2H, 2H-heptadecafluorodecyl) silane dropwise, and then add the prepared absolute ethanol: water 20ml of ethanol aqueous solution with a volume ratio of 9:1, ultrasonically dispersed for 20 minutes, condensed and refluxed in an oil bath at 65°C for 5 hours. Then, the modified epoxy resin solution that has been reacted is evaporated to dryness with a rotary evaporator, and finally centrifuged to obtain the modified epoxy resin;

[0030] Weigh 5.66g of diethylenetriamine, 1.5g of sodium ethoxide, and 50ml of absolute ethanol. First, ultrasonically disperse for 15 minutes, then stir in an oil bath under nitrogen protection for 1 hour, set the temperature to 70°C, and then add 11g of methyl Tridecafluorooctyl acrylate continued to react for 23 hours, the crude product was rotary evaporated to remove the solvent, added deionized water to wash until neutral, and then filtered to obtain a modified ...

Embodiment 3

[0035] Weigh 1.9818g of EP CYD-127 type epoxy resin, then add 0.5356g of trimethoxy (1H,1H,2H,2H-heptadecafluorodecyl) silane dropwise, and then add the prepared absolute ethanol: water 20ml of ethanol aqueous solution with a volume ratio of 9:1, ultrasonically dispersed for 20 minutes, condensed and refluxed in an oil bath at 65°C for 5 hours. Then, the modified epoxy resin solution that has been reacted is evaporated to dryness with a rotary evaporator, and finally centrifuged to obtain the modified epoxy resin;

[0036] Weigh 5.66g of diethylenetriamine, 1.5g of sodium ethoxide, and 50ml of absolute ethanol. First, ultrasonically disperse for 15 minutes, then stir in an oil bath under nitrogen protection for 1 hour, set the temperature to 70°C, and then add 11g of methyl Tridecafluorooctyl acrylate continued to react for 23 hours, the crude product was rotary evaporated to remove the solvent, added deionized water to wash until neutral, and then filtered to obtain a modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com