Catalyst for preparing polymercaptan curing agent and application thereof

A technology for a polythiol curing agent and a catalyst, which is applied in the field of polythiol compounds, can solve the problems of large industrial-scale production and application limitations, high production and separation costs, difficult recovery of catalysts, etc., and achieves good industrial application prospects and halogen residues. Low, reduced wastewater discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

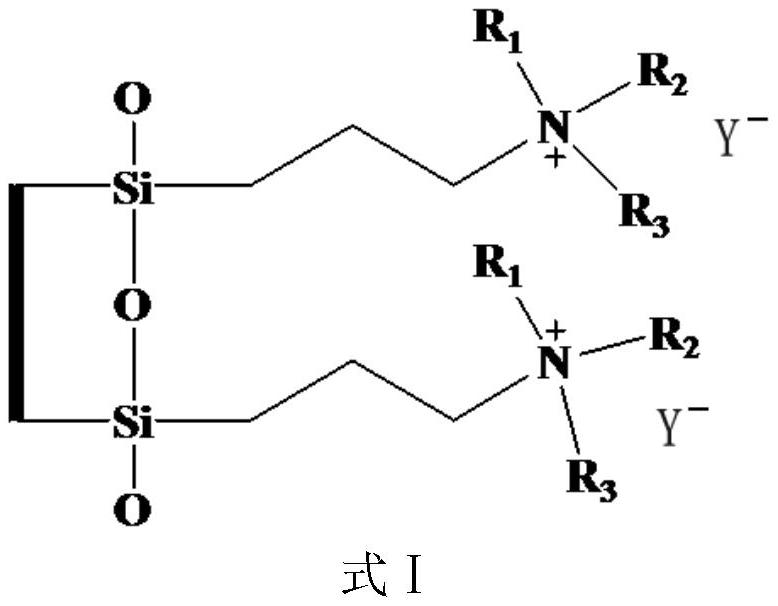

[0051] Preparation of catalyst QA-SBA-15:

[0052] (1) Halogenated SBA-15 process: in N 2 Under the atmosphere, add 2g of SBA-15 to a solution of 50mM 3-chloropropyltriethoxysilane (2g) in absolute ethanol, and after reflux for 24h, filter the mixture with suction and wash with absolute ethanol at 80°C. Dry overnight under vacuum, and the obtained solid is halogenated SBA-15.

[0053] (2) Synthesis of QA-SBA-15: 2 g of dried halogenated SBA-15 was placed in a 150 mL three-necked flask, and a mixed solvent of 50 mL of 1,2-dichloroethane and 50 mL of absolute ethanol was added. Add tri-n-butylamine according to the molar ratio n(Cl):n(amine)=1:3, reflux for 12 hours, separate by suction filtration, wash with ethanol, and dry in the air. Then use a Soxhlet extractor to add absolute ethanol to extract for 12 hours to remove unreacted tertiary amines in the pores, and finally vacuum-dry at room temperature to constant weight to obtain catalyst QA-SBA-15.

Embodiment 2

[0055] Catalyst QA-SBA-15 is prepared with reference to Example 1, the halogenation reagent is selected from 3-bromopropyltriethoxysilane (1.2), and during QA-SBA-15 synthesis, n(Cl):n(amine)=1:4.2 , and the rest of the reaction conditions remained unchanged.

Embodiment 3

[0057] Catalyst QA-SBA-15 was prepared with reference to Example 1, and the halogenation reagent was selected from 3-chloropropyltriethoxysilane (3.2g). When QA-SBA-15 was synthesized, n(Cl):n(amine)=1: 2.7, choose tri-n-propane as the tertiary amine, and keep the rest of the reaction conditions unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com