Method for preparing hierarchical porous material based on rapid solvent evaporation in inverse microemulsion system

An inverse microemulsion, multi-level pore technology, applied in carbon preparation/purification, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of long and complex reaction process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

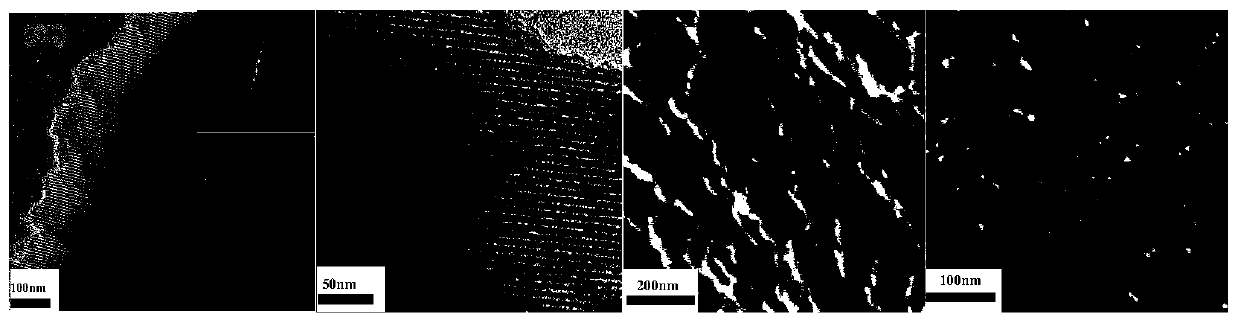

[0029] Take 0.8g of tri-block surfactant polyether F127 and dissolve it in 8ml of methyl methacrylate. After F127 is completely dissolved, add 0.5ml of ethanol and 0.2ml of water drop by drop. The formation of water nuclei was observed in the methyl ester, and then continued to stir until the solution was completely dissolved and clarified, then added 0.246g of resorcinol and 0.204g of terephthalaldehyde as carbon source precursors, and after it was completely dissolved, added 0.0056g of carbonic acid Sodium is used as the catalyst of the reaction to adjust the pH value to 12, followed by stirring for 6 hours until the solution turns dark red, and the high-temperature solvent is evaporated at 120°C for 10 minutes to obtain a black solid product, which is passed through a tube furnace for 800 ℃ high temperature calcination to obtain the final carbon porous material.

Embodiment 2

[0031] Take 0.8g of tri-block surfactant polyether F127 and dissolve it in 8ml of methyl methacrylate. After F127 is completely dissolved, add 0.5ml of ethanol and 0.2ml of water drop by drop. The formation of water nuclei was observed in the methyl ester, and then the stirring was continued until the solution was completely dissolved and clarified, then 1.04 g of tetraethyl orthosilicate, 0.246 g of resorcinol and 0.204 g of terephthalaldehyde were added as precursors of silicon and carbon sources , after it is completely dissolved, add 0.0056g of sodium carbonate as a reaction catalyst to adjust the pH value to 12, then stir for 6 hours, evaporate the solvent at 130°C for 10 minutes to obtain a black solid product, and the solid product is in the tube After being calcined at a high temperature of 800°C in a furnace, the calcined product is corroded by a 5wt% HF solution to obtain the final silicon-carbon hierarchical porous material. Depend on Figure 7 It can be seen that ...

Embodiment 3

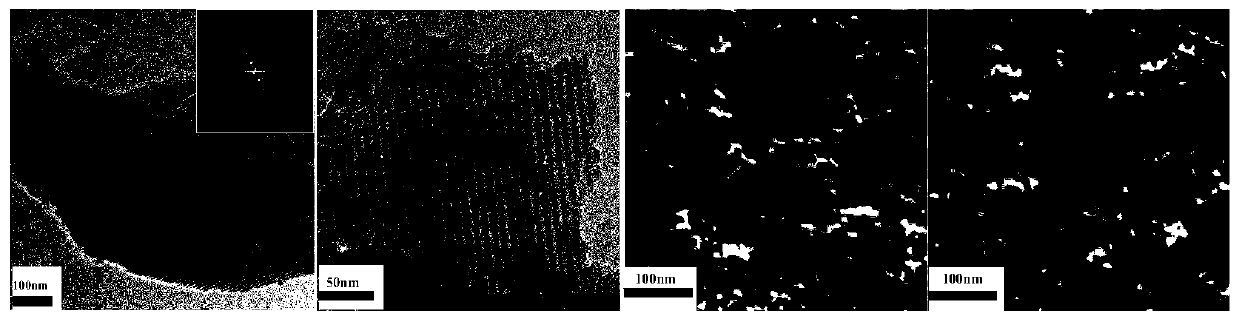

[0033] Take 0.8g of tri-block surfactant polyether F127 and dissolve it in 8ml of methyl methacrylate. After F127 is completely dissolved, add 0.5ml of ethanol and 0.2ml of water drop by drop. The formation of water nuclei was observed in the methyl ester, and then continued to stir until the solution was completely dissolved and clear, then added 8 mmmol of 1,4 (bistriethoxysilyl) benzene and 0.02 ml of concentrated HCl, adjusted the pH to 2, and stirred thoroughly for 12 hours Finally, the high-temperature solvent was evaporated at 140°C for 10 minutes, and the obtained white solid product was refluxed for 24 hours in a solution of concentrated HCl and ethanol with a volume ratio of 3.6:120 to obtain a silicon hierarchical porous material. Depend on Figure 8 It can be seen that the prepared silicon material is hierarchically porous.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com