A run-length-based method for marking abnormal regions of thermal images of crystallizers

A technology of abnormal area and marking method, which is applied in the field of iron and steel metallurgical continuous casting, can solve the problems of not considering the inclusion characteristics of abnormal areas in the thermal image, and it is difficult to meet the requirements of online detection, so as to reduce storage space, accurately mark, and have strong applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

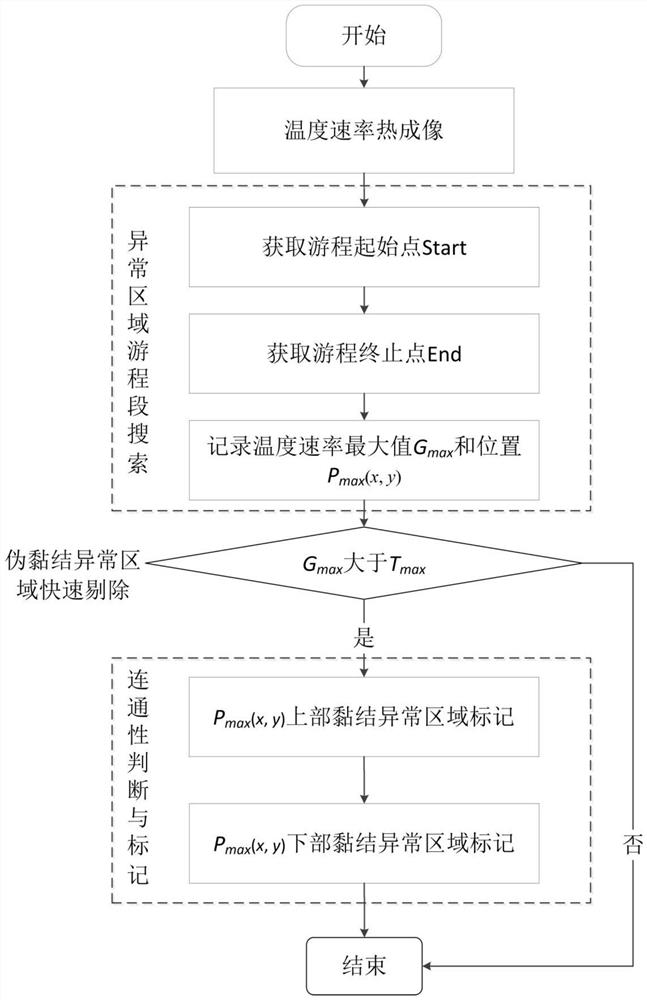

[0047] A run-based method for marking abnormal regions of crystallizer thermal images according to the present invention comprises the following steps:

[0048] 1) Thermography of the temperature rate of the mold copper plate

[0049] ①Based on the temperature data of mold thermocouples detected online, identify abnormalities in temperature data, and establish a database of billet bonding samples in the mold;

[0050] ②Based on the thermocouple temperature of the crystallizer bonding sample, the temperature at the non-galvanic measuring point is calculated by interpolation, and the temperature rate G[x,y] of the four copper plates is calculated;

[0051] ③According to the corresponding relationship between the temperature rate and the color, the temperature rate thermal image of the mold copper plate is drawn, and the abnormal bonding area in the mold is visualized;

[0052] 2) Run segment search for the area where the slab bonded abnormally

[0053] ①From left to right, from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com