Resource recovery method and resource recovery system for desulfurized fly ash

A technology of resource recovery and desulfurization ash, which is applied in resource recovery system and resource recovery field of desulfurization ash, can solve the problems of desulfurization ash difficult to handle and comprehensive utilization, and achieve the effect of recycling and reuse, significant economic benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

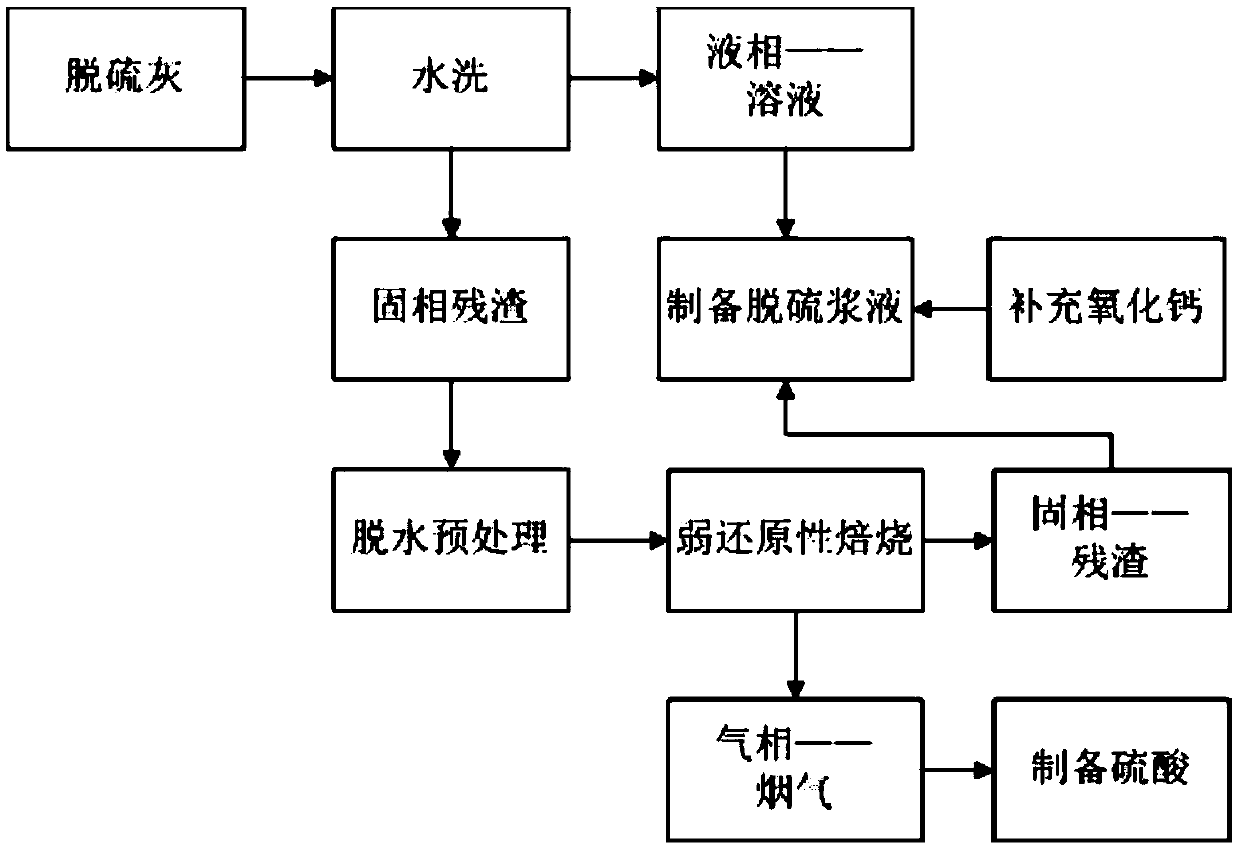

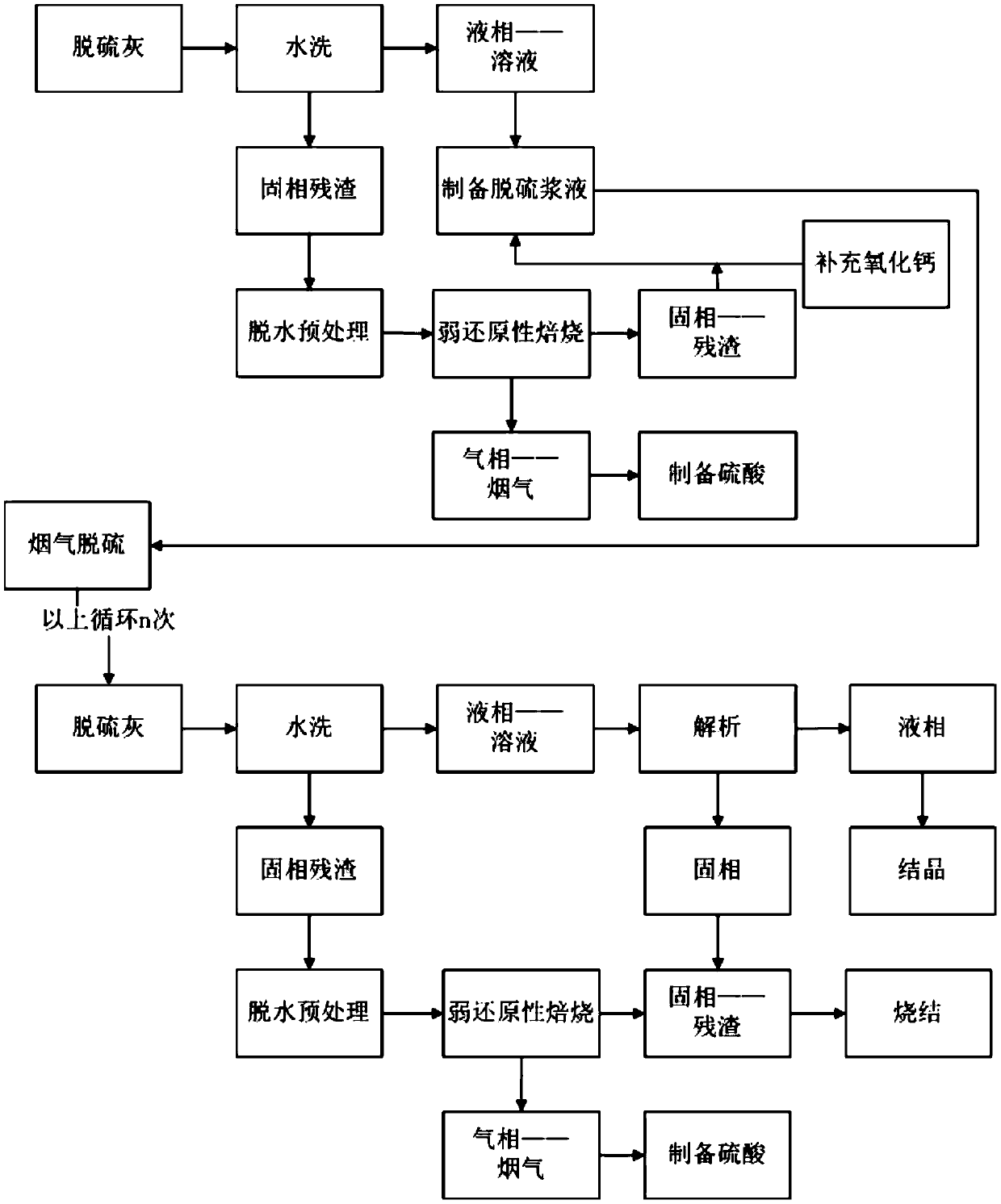

[0039] ginseng figure 1 , provides a first embodiment of a resource recovery method for desulfurized ash, which can realize efficient treatment of desulfurized ash, and realize the recovery of sulfur, calcium and other elements in the desulfurized ash, so that the desulfurized ash can produce high value-added Resource utilization, and no solid waste, liquid waste, gas waste, etc. are generated in the whole process, which is economical and environmentally friendly. Specifically, the resource recovery method includes the following steps.

[0040] Water washing process: wash the desulfurization ash with water, and obtain a solid residue rich in calcium sulfite and calcium sulfate and a solution rich in calcium hydroxide after solid-liquid separation

[0041] The main components of desulfurization ash generally include: calcium sulfite, calcium sulfate, calcium oxide, calcium carbonate, calcium hydroxide, etc. The desulfurization ash can be specifically selected from any one of ...

Embodiment approach

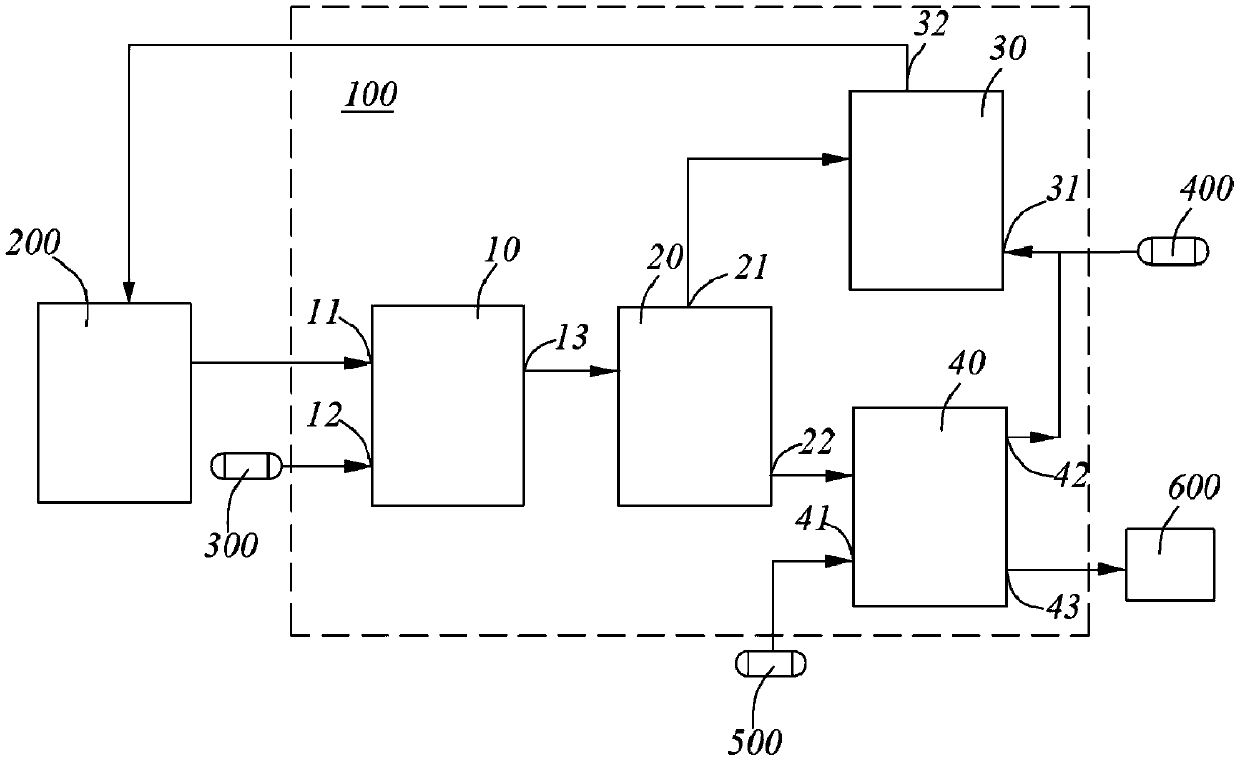

[0067] ginseng figure 2 , also provides a first embodiment of a resource recovery system 100 for desulfurization ash, the resource recovery system can be used to implement the resource recovery method of the first embodiment described above, the following can be combined with the above-mentioned resource recovery method Introduction to understand the structure and functions of the resource recovery system 100 .

[0068] Specifically, the resource recovery system 100 includes a water washing reaction tank 10 , a solid-liquid separation device 20 , a desulfurization slurry preparation device 30 and a roasting reactor 40 .

[0069] The water washing reaction tank 10 has a desulfurization ash input port 11 and a water inlet port 12 . As the name implies, the desulfurization ash input port 11 can be used to introduce the desulfurization ash into the water washing reaction tank 10, and it can be connected to the desulfurization ash outlet of the external desulfurization reactor 20...

Embodiment 1

[0088] Get the desulfurization ash produced by the semi-dry desulfurization process in the semi-dry desulfurization reactor 200, and send it to the washing reaction tank 10 for washing, wherein the mass ratio of water and desulfurization ash in the washing reaction tank 10 is greater than 20:1, And, under the agitation of the agitation device in the water washing reaction tank 10, the desulfurization ash and water are fully mixed evenly to obtain a mixed solution;

[0089] The mixed solution in the washing reaction tank 10 is transported to the solid-liquid separation device 20 for solid-liquid separation, the separated liquid phase is a solution rich in calcium hydroxide, and the separated solid phase is rich in calcium sulfate, Solid residues of calcium sulfate and calcium carbonate;

[0090] The solid residue rich in calcium sulfate, calcium sulfite, and calcium carbonate first enters the compression dehydration equipment for compression dehydration pretreatment, and then e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com