Diversified waste gas treatment system

A technology for waste gas treatment and waste gas, which is used in gas treatment, chemical instruments and methods, combined devices, etc., can solve the problems of unsuitable use, inability to meet the needs of various types of waste gas treatment, and high cost, and achieve good purification effect and save removal. Oil equipment, avoid the effect of collecting dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

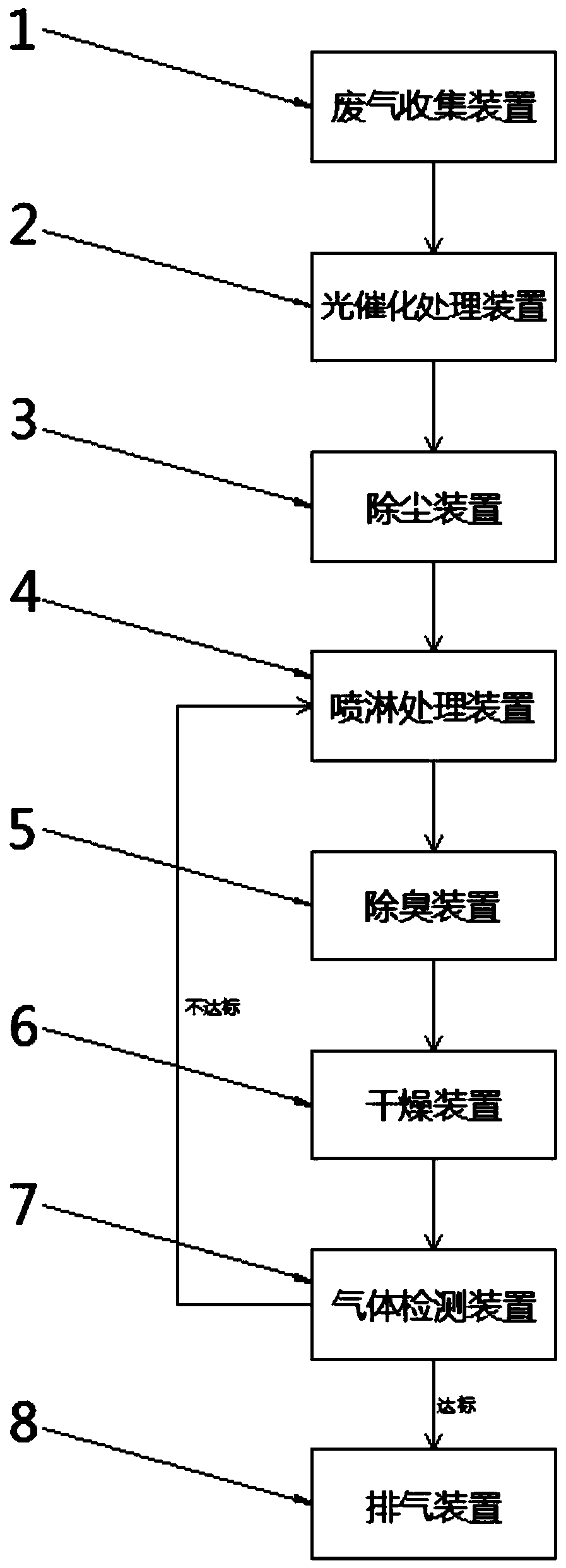

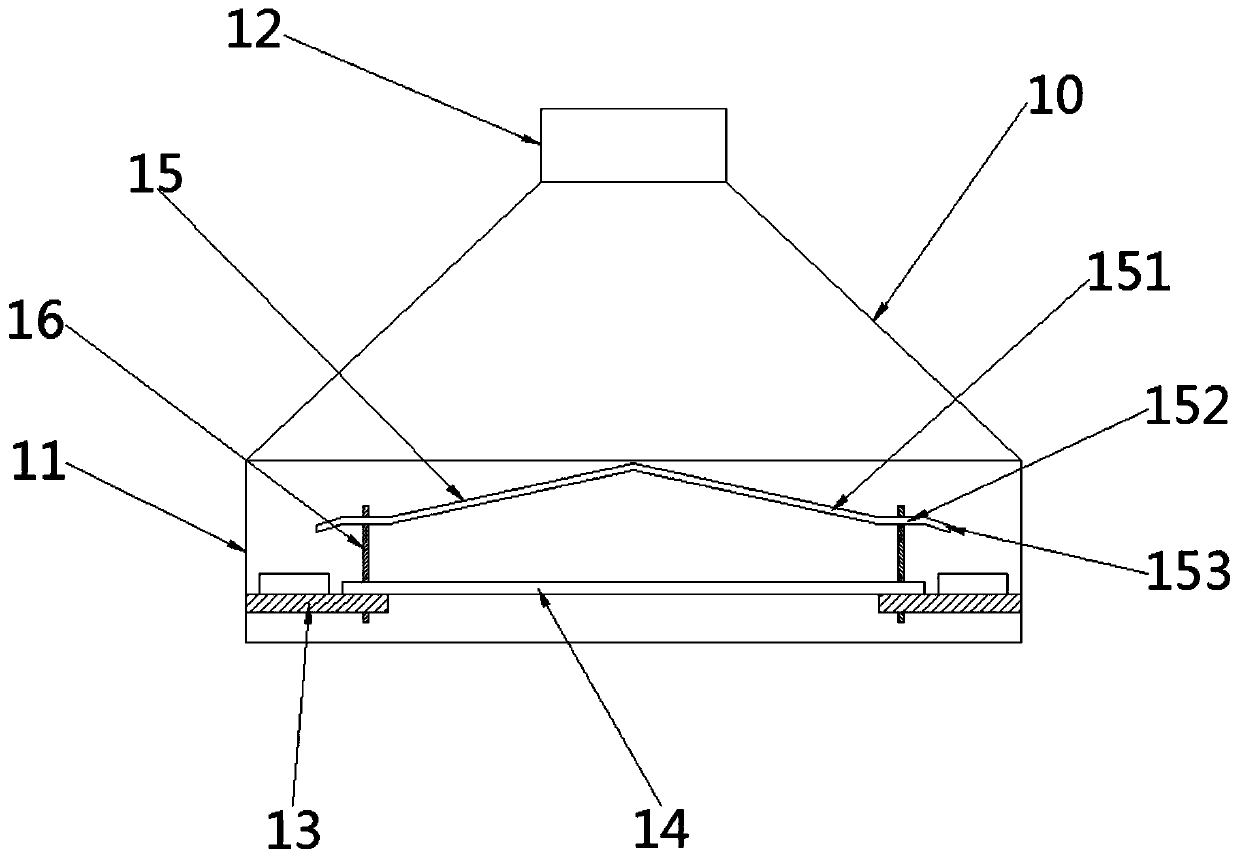

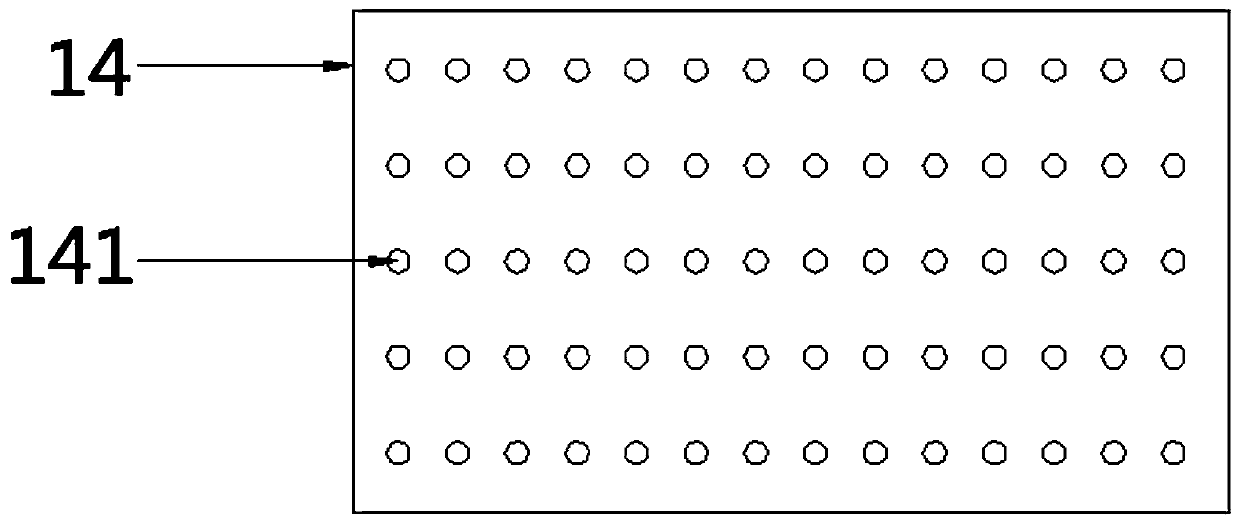

[0040] See Figure 1-4 , A diversified exhaust gas treatment system, including exhaust gas collection device 1, photocatalytic treatment device 2, dust removal device 3, spray treatment device 4, deodorization device 5, drying device 6, gas detection device 7 and Exhaust device 8, the working process of the diversified exhaust gas treatment system specifically includes the following steps:

[0041] Exhaust gas collection: The exhaust gas collection device 1 collects the exhaust gas and introduces the exhaust gas into the photocatalytic treatment device 2 for processing;

[0042] Photocatalytic treatment: The photocatalytic treatment device 2 performs a photocatalytic reaction on the collected exhaust gas, converts organic matter into inorganic matter, and introduces the treated exhaust gas into the dust removal device 3;

[0043] Dust removal treatment: The dust removal device 3 performs dust removal treatment on the waste gas after the photocatalytic treatment, filters out larger p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com