Wheel type vacuum chuck structure climbing cleaning trolley for glass curtain wall

A vacuum suction cup and glass curtain wall technology, applied in the field of climbing and cleaning trolleys, can solve the problems of high work intensity, prone to accidents, slow climbing, etc., and achieve the effect of high cleaning efficiency and efficient climbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0025] The invention provides a wheeled vacuum suction cup structure climbing and cleaning trolley for glass curtain walls. The vacuum suction cup structure adopts an original wheel structure, and the generation and destruction of vacuum in the gas path of different suction cups can be realized through the movement of two gas path components. Thereby climbing can be realized, and the cleaning of the glass curtain wall can be completed by cooperating with the corresponding cleaning mechanism.

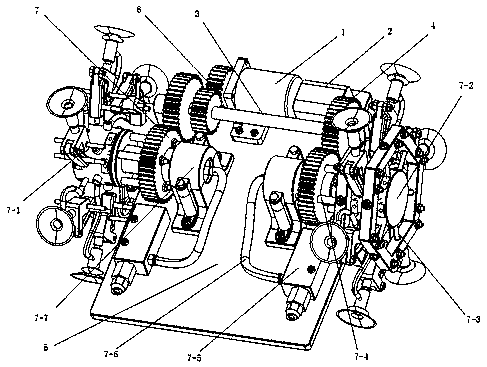

[0026] As an embodiment of the present invention, the present invention provides such as Figure 1-2 Shown is a wheeled vacuum suction cup structure climbing cleaning trolley for glass curtain walls, including a motor 1, a battery pack 2, a gear shaft 3, a side drive gear set 4, a frame 5, a main drive gear set 6, and a wheeled suction cup Structure 7, bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com