Power semiconductor module

A power semiconductor and molding technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., to achieve the effect of improving long-term reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Reference will now be made in detail to the exemplary embodiments illustrated in the drawings. This example is provided by way of explanation and is not intended to be limiting. It is intended that the present disclosure includes such modifications and variations.

[0076] Within the following description of the drawings, the same reference numbers refer to the same components. In general, only the differences with respect to individual embodiments are described. When several identical items or parts appear in a drawing, not all parts have a reference number in order to simplify the layout.

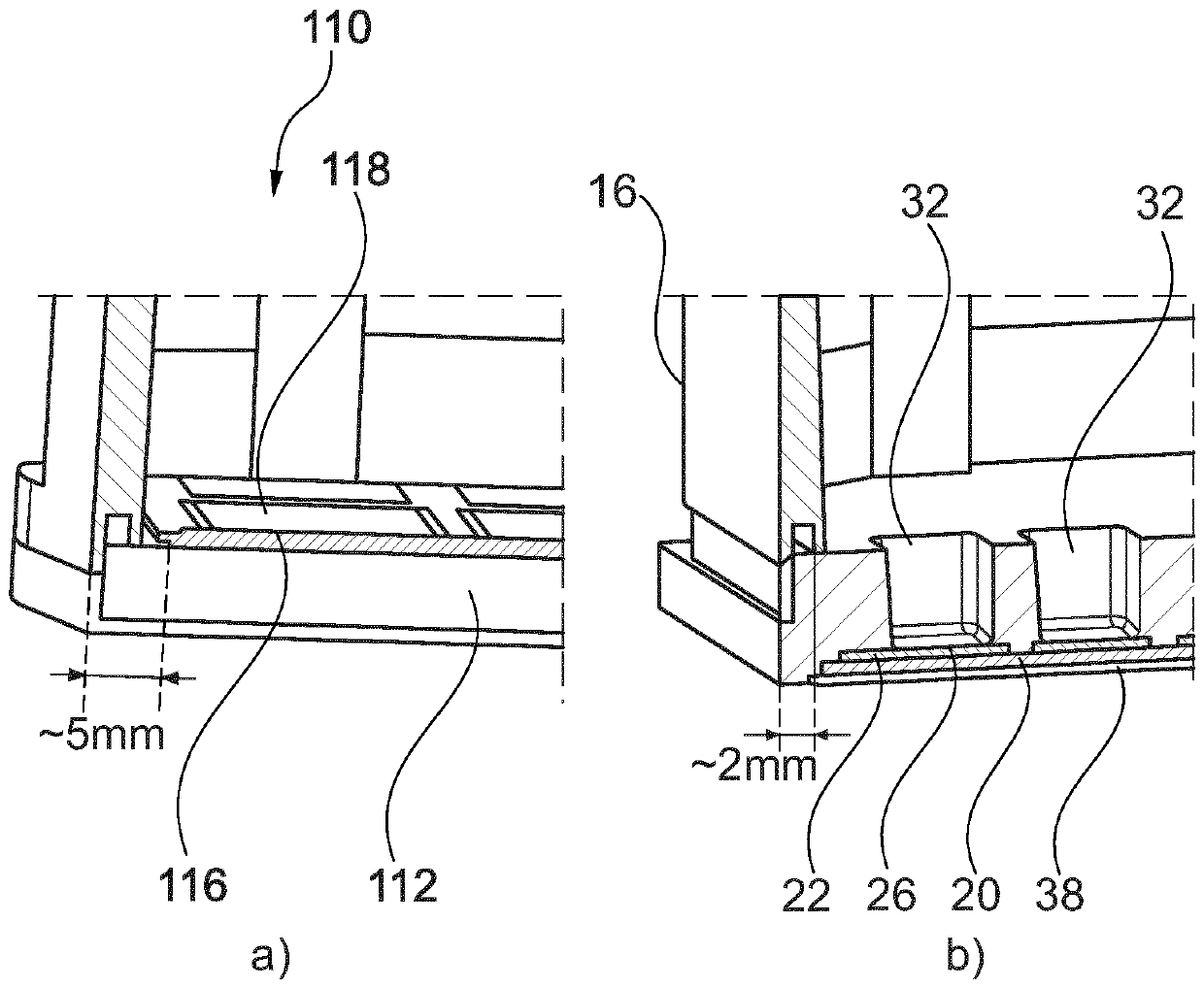

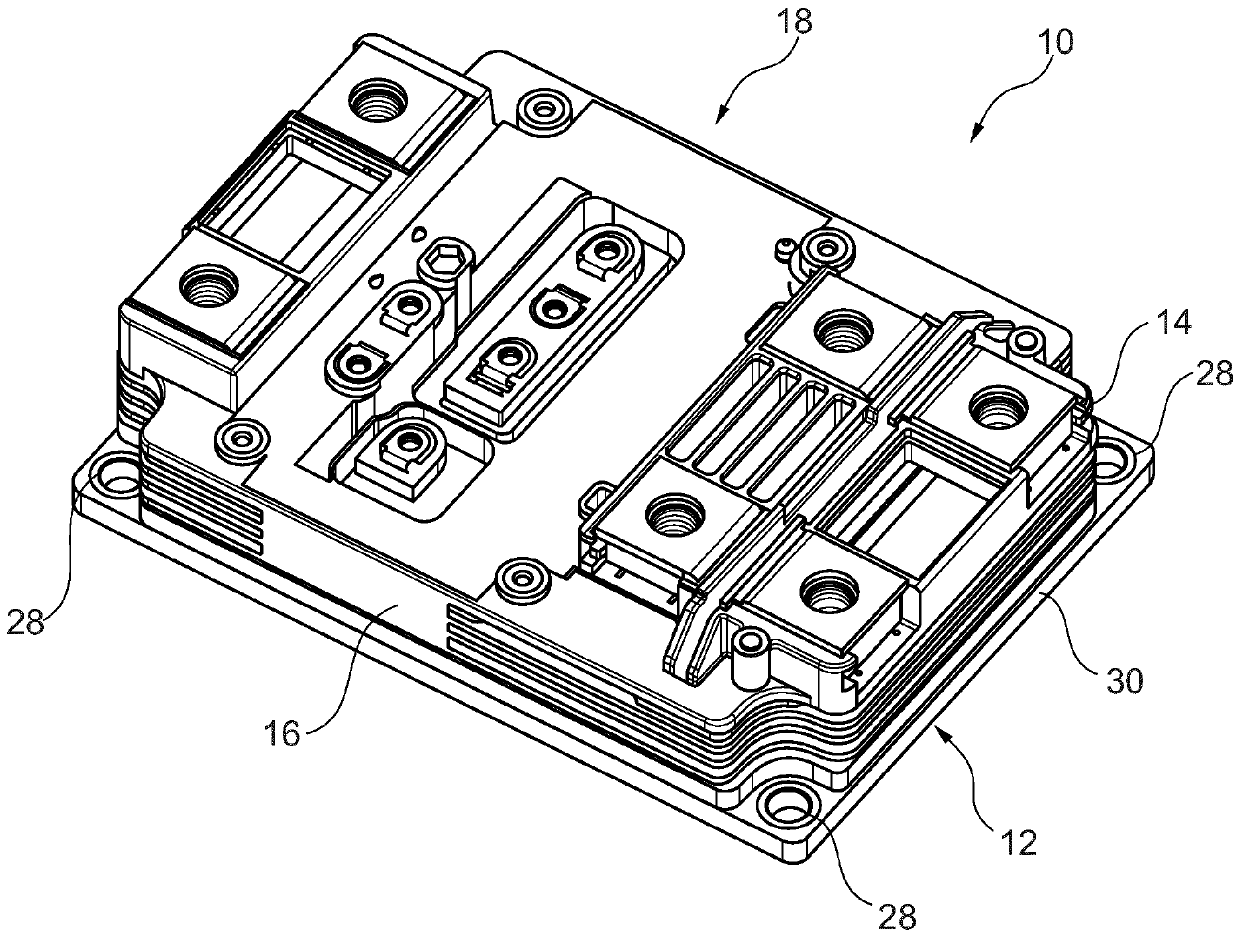

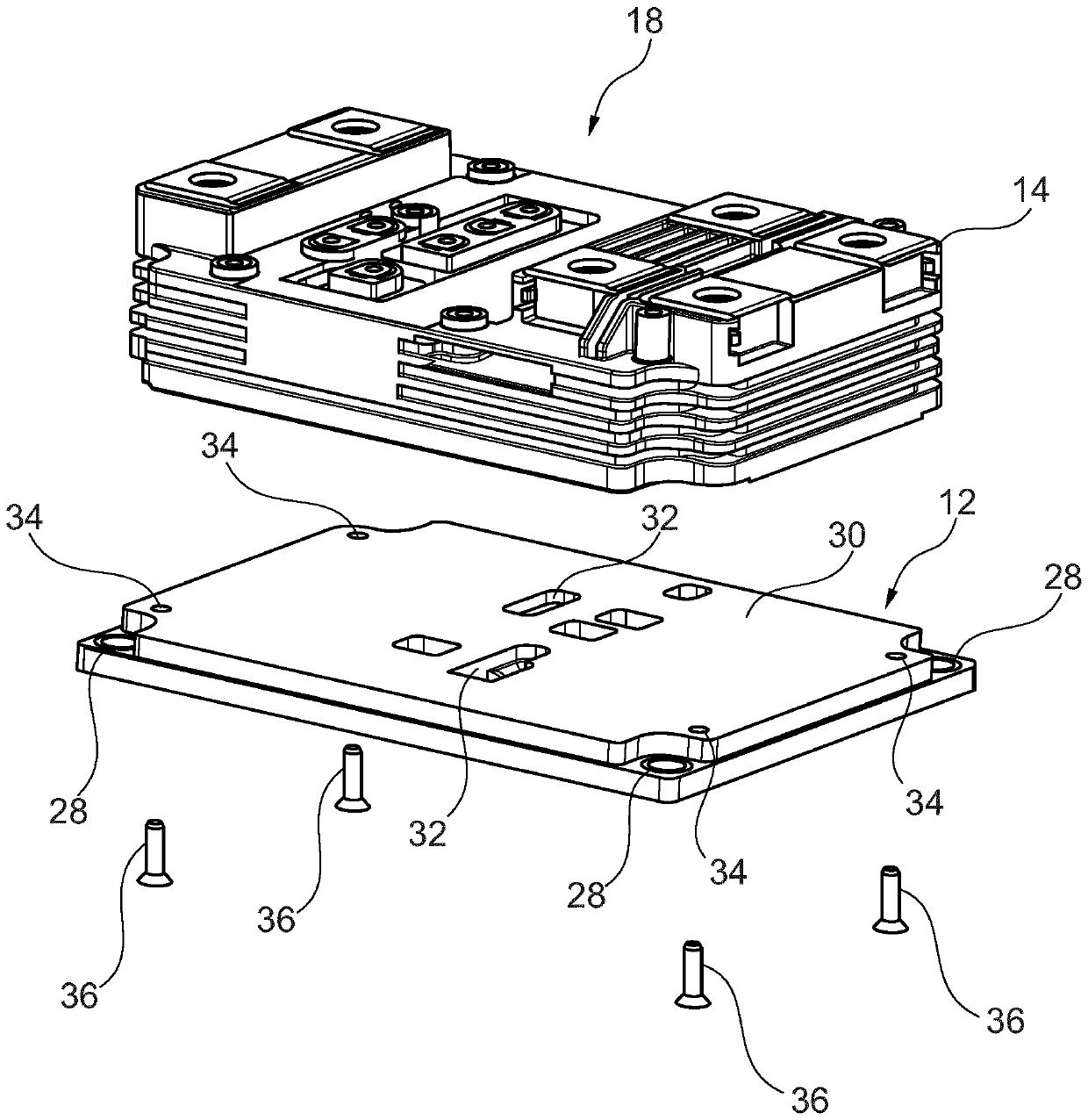

[0077] figure 1 A power semiconductor module 10 is shown. The power semiconductor module 10 includes a substrate 12 and a housing 14 . exist figure 2 and image 3 In , the substrate 12 is shown in more detail. As described in more detail below, the housing 14 includes a circumferential side wall 16 . Furthermore, the housing includes its active peripherals 18 including, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com