Method and device for measuring a layer thickness of an object

A technology for objects and equipment, applied in the field of layer thickness of plastic objects, to achieve efficient coverage of bandwidth, avoid redundancy, and avoid related difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

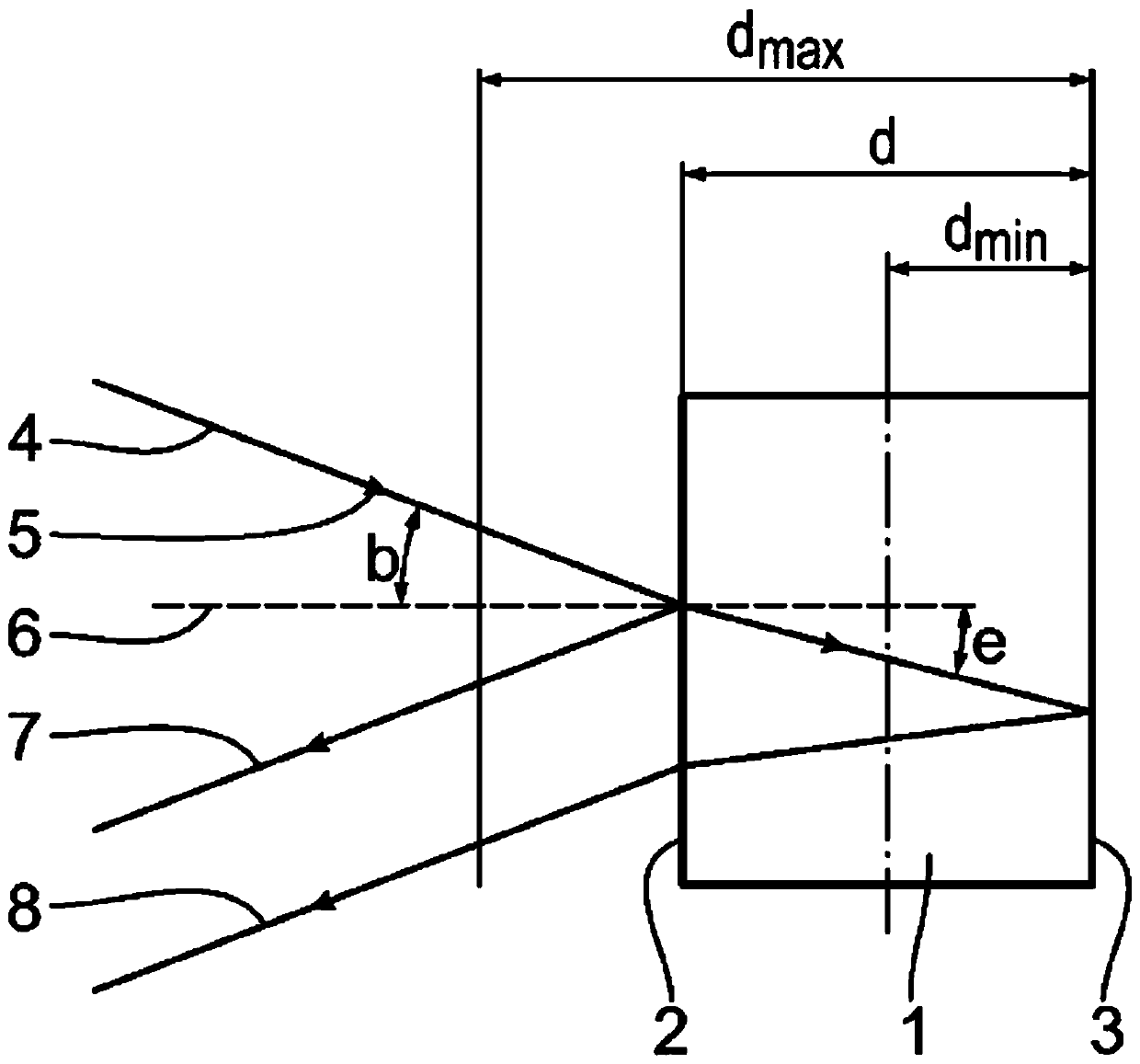

[0063] figure 1 The measurement of the layer thickness d of the object 1 is shown schematically. The object 1 has boundary surfaces 2 , 3 separated by a layer thickness d. The layer thickness d of object 1 is at the minimum layer thickness d min with the maximum layer thickness d max Changes in the range between. Minimum layer thickness d min and the maximum layer thickness d max Indicates the minimum or maximum layer thickness to be measured for the measurement. The refractive index n of the object 1 deviates from the refractive index of the surrounding environment of the object 1 . Typically, measurements are made in air or a vacuum, so the environment has a refractive index of 1.

[0064] In order to measure the layer thickness d of the object 1 , electromagnetic radiation 4 is incident on the boundary surface 2 of the object 1 at an angle of incidence b. The angle of incidence b is defined as the angle between the direction of propagation 5 of the electromagnetic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com