Novel SCR denitration device efficiency calculation method

A technology for efficiency calculation and denitrification efficiency, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of not considering the flue gas flow rate, simple calculation method, etc., and achieve accurate and accurate flue gas nitrogen oxide concentration Scientific, high practical value, scientific effect of pollutant concentration calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described in detail through the following examples, but the technical content described in this example is illustrative rather than limiting, and should not limit the protection scope of the present invention accordingly.

[0026] A new method for calculating the efficiency of an SCR denitrification device. The innovation of the present invention lies in: setting sampling points at the inlet and outlet of the SCR denitrification device, and sampling and measuring the flue gas flow rate, oxygen content and nitrogen oxide content at each sampling point;

[0027] The calculation method includes the following steps:

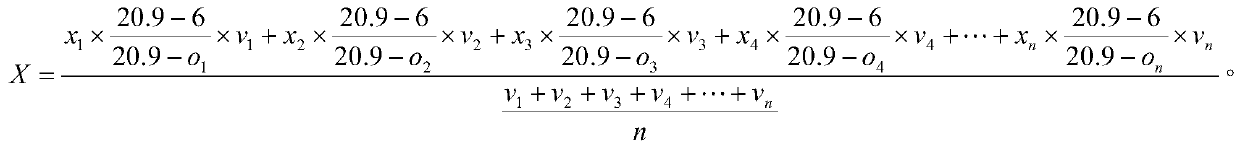

[0028] (1) Calculate the average concentration of nitrogen oxides at the inlet;

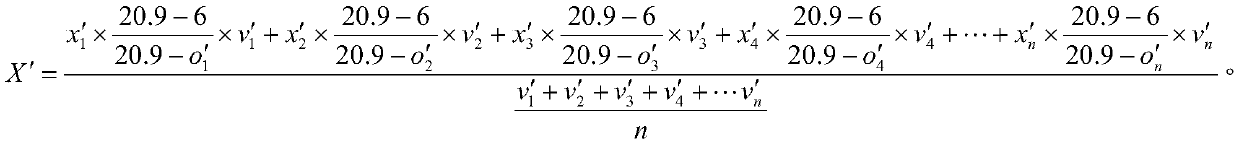

[0029] (2) Calculate the average concentration of nitrogen oxides at the outlet;

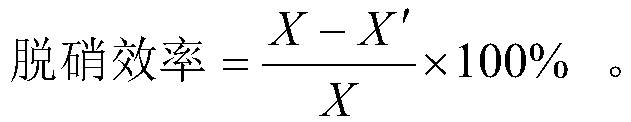

[0030] (3) Calculate the denitrification efficiency.

[0031] Again, the calculation process of the inlet nitrogen oxide average concentration described in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com