Automatic manufacturing device of blood smear

A technology for making a device and a blood smear, which is applied in the field of medical devices, can solve the problems of large workload of manually making smears, difficult to meet the requirements of testing, and reduced testing efficiency, and achieves improved production efficiency, convenient removal, and accelerated drying. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

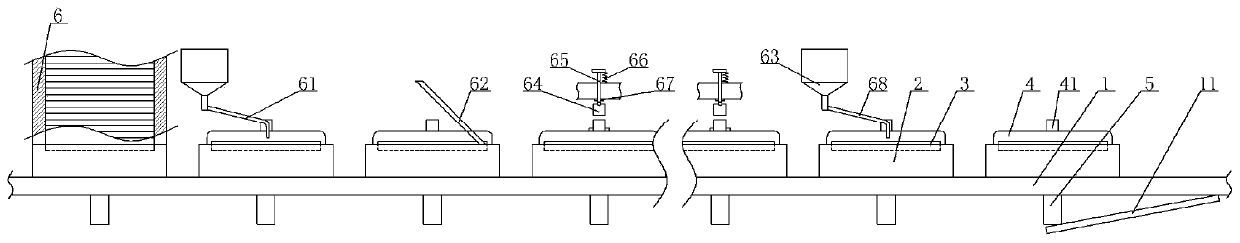

[0037] Automatic production equipment for blood smears, such as figure 1 and figure 2As shown, it includes a frame, a transmission unit, a dropper 61, a pusher, a drying tube and a dyeing tube 68. The transmission unit includes a conveyor belt 1 and a transmission drive. The transmission drive in this embodiment selects a geared motor, and the transmission drive It is fixed on the frame by bolts, and the left and right ends of the frame are equipped with rotating shafts. The rotating shaft runs through the frame and there are bearings between the two ends of the rotating shaft and the frame. A driven gear is fixed on the top through a flat key, and an incomplete gear meshing with the driven gear is connected to the output shaft of the rotating drive part through a coupling, and the rotating drive part drives the conveyor belt 1 to rotate intermittently clockwise.

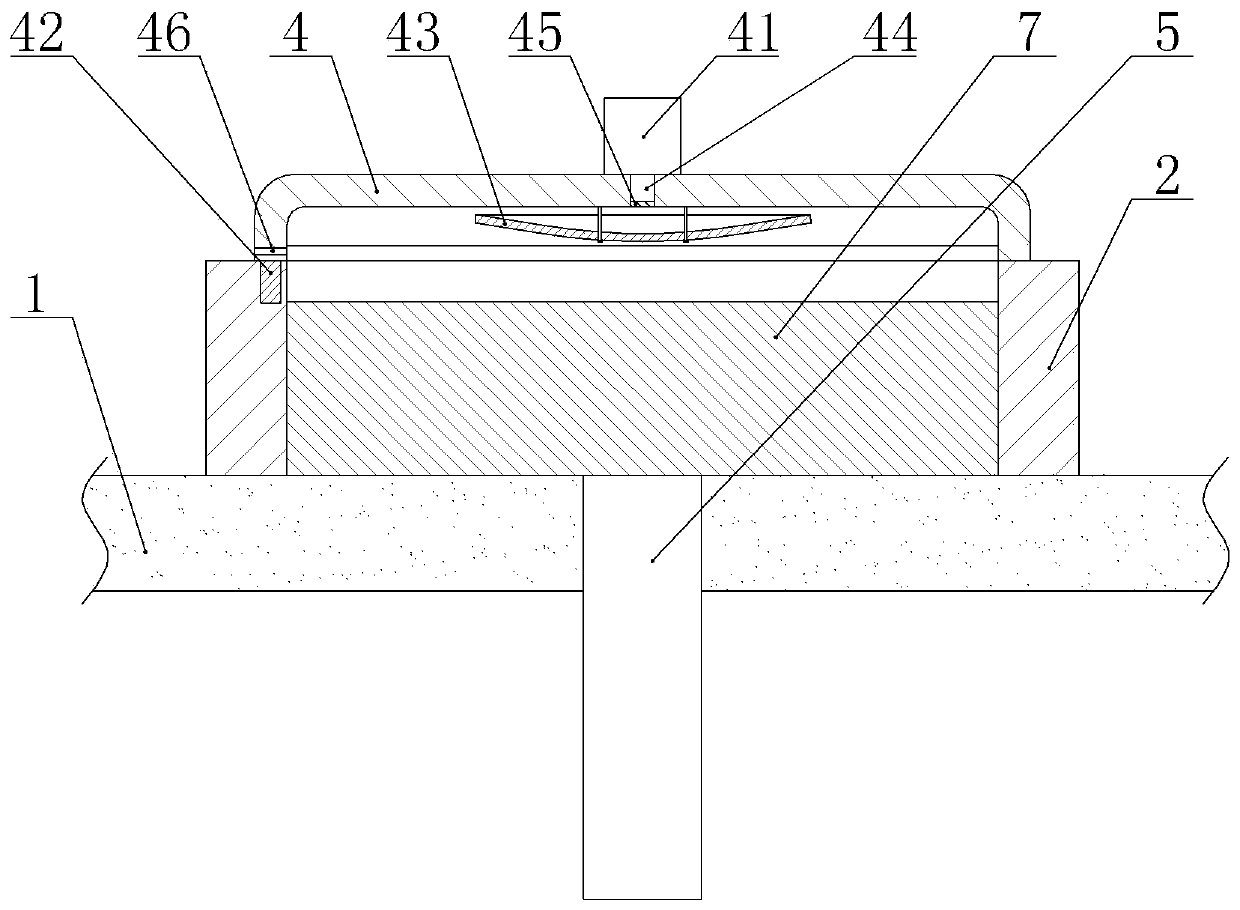

[0038] On the conveyor belt 1, several placement plates 7 are arranged at uniform intervals along the length di...

Embodiment 2

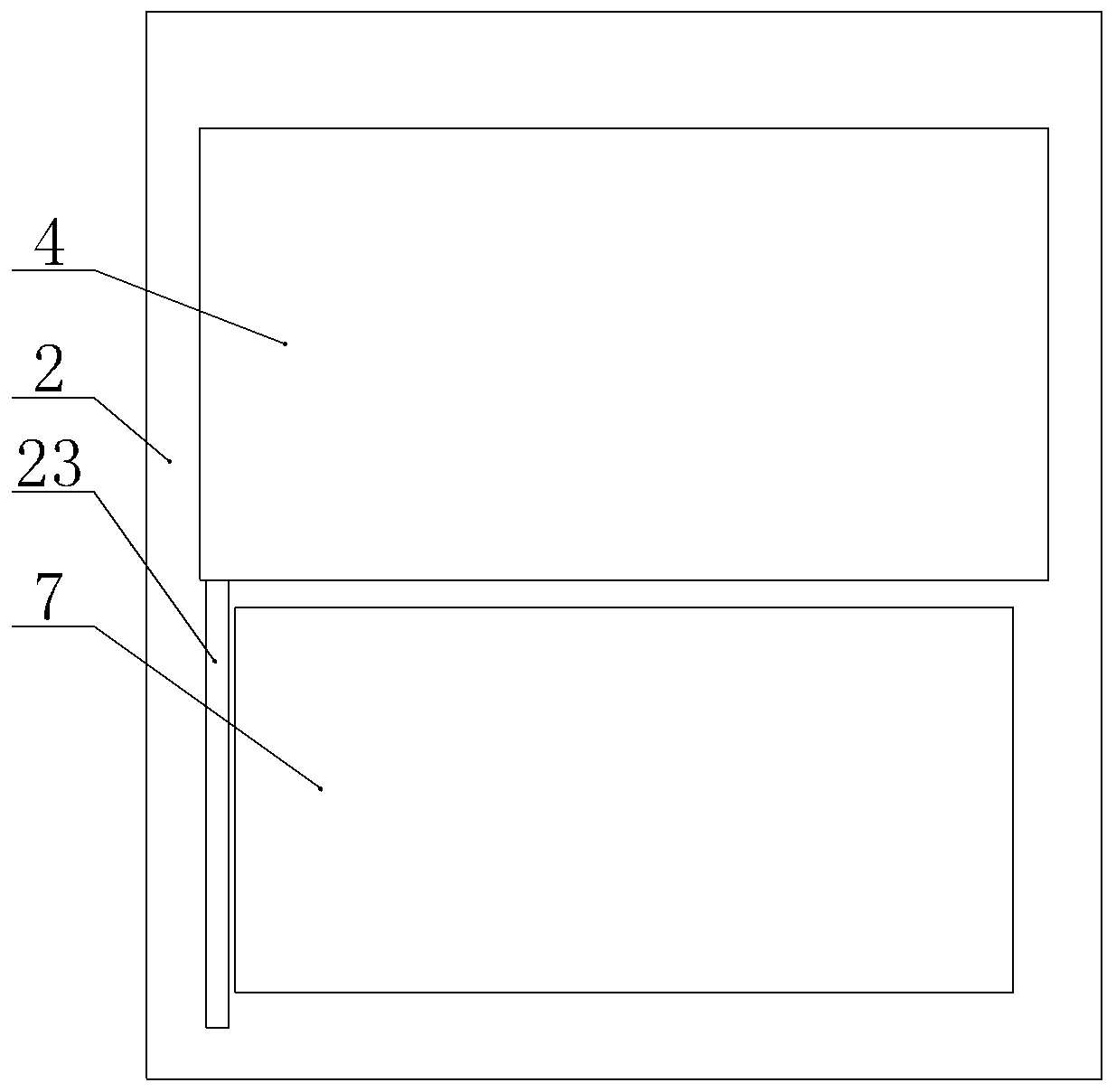

[0050] On the basis of Example 1, such as Figure 4 , Figure 5 and Figure 6 As shown, the placement plate 7 in this embodiment is provided with a negative pressure chamber and a hot gas chamber 75 located below the negative pressure chamber. A second piston 71 is slidably sealed in the negative pressure chamber. The second piston 71 is arranged laterally and the second piston 71 divides the negative pressure chamber into an upper adsorption chamber 72 and a lower exhaust chamber 74. The top of the adsorption chamber 72 is provided with a number of adsorption holes 73, and the left wall of the exhaust chamber 74 is provided with a first pressure relief hole 21. The wall is provided with a second pressure relief hole 76 communicating with the first pressure relief hole 21, and a second spring is arranged in the exhaust chamber 74, and the two ends of the second spring are respectively welded to the second piston 71 and the bottom of the exhaust chamber 74.

[0051] Two teles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com