220kV framework structure suitable for large slope site

A site and slope technology, which is applied in the field of civil engineering structure professional frame and 220kV frame structure, can solve the problems of potential safety hazards, insufficient height of frame beam bottom from the ground, and difficult design of 220kV frame structure foundation, so as to improve production efficiency and reduce site excavation. The effect of filling amount and meeting the drainage requirements of the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

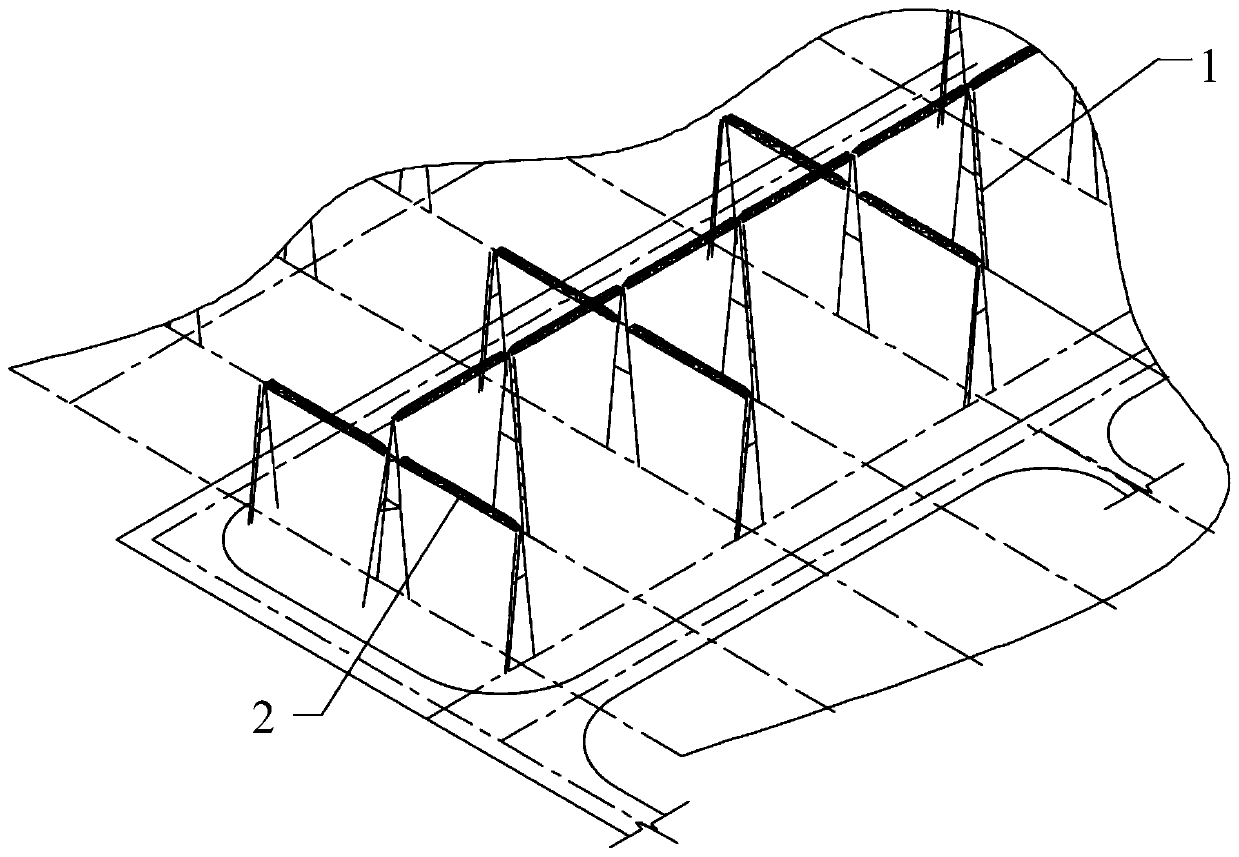

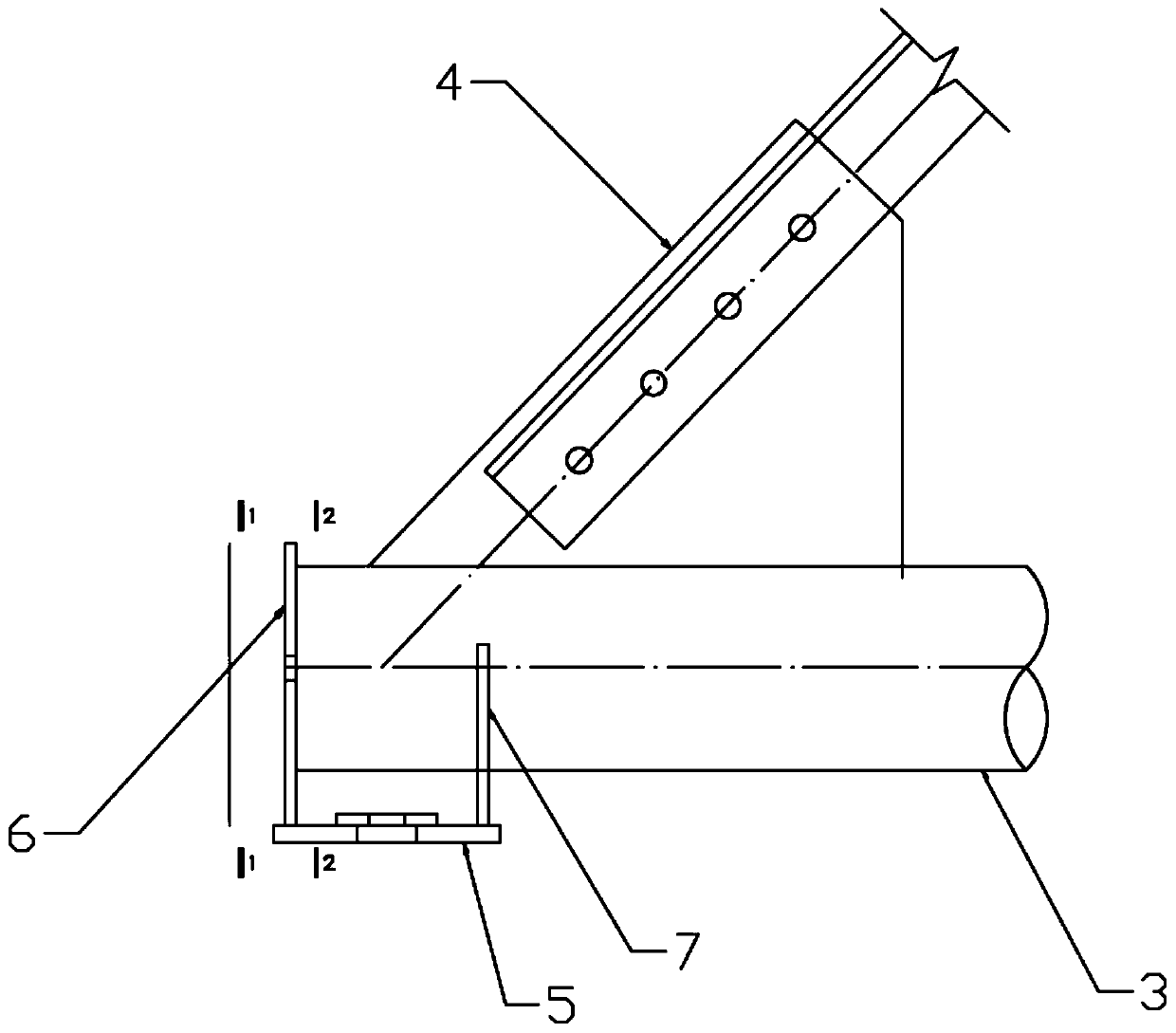

[0028] like Figure 1-Figure 4 As shown, in this embodiment, a 220kV frame structure suitable for sites with relatively large slopes is specifically provided, including several frame columns 1. In this site, each frame column 1 is arranged in a horizontal and vertical manner, and each The bottom ends of the frame columns 1 are buried in the site at the same depth, and the embedment depths of each frame column 1 are the same. If the site is simulated as a standard slope, the vertical distance between the top of each frame column 1 and the surface of the site is Equal spacing can also be understood as the apex of each frame column 1 is connected to form a "surface", and the "surface" should be parallel to the slope of the site.

[0029] At least one frame beam 2 is arranged between two adjacent frame columns 1, and the number of frame beams 2 is the 220Kv layout site requirements, depending on the actual situation; the two ends of the frame beam 2 pass through The leveling supp...

Embodiment 2

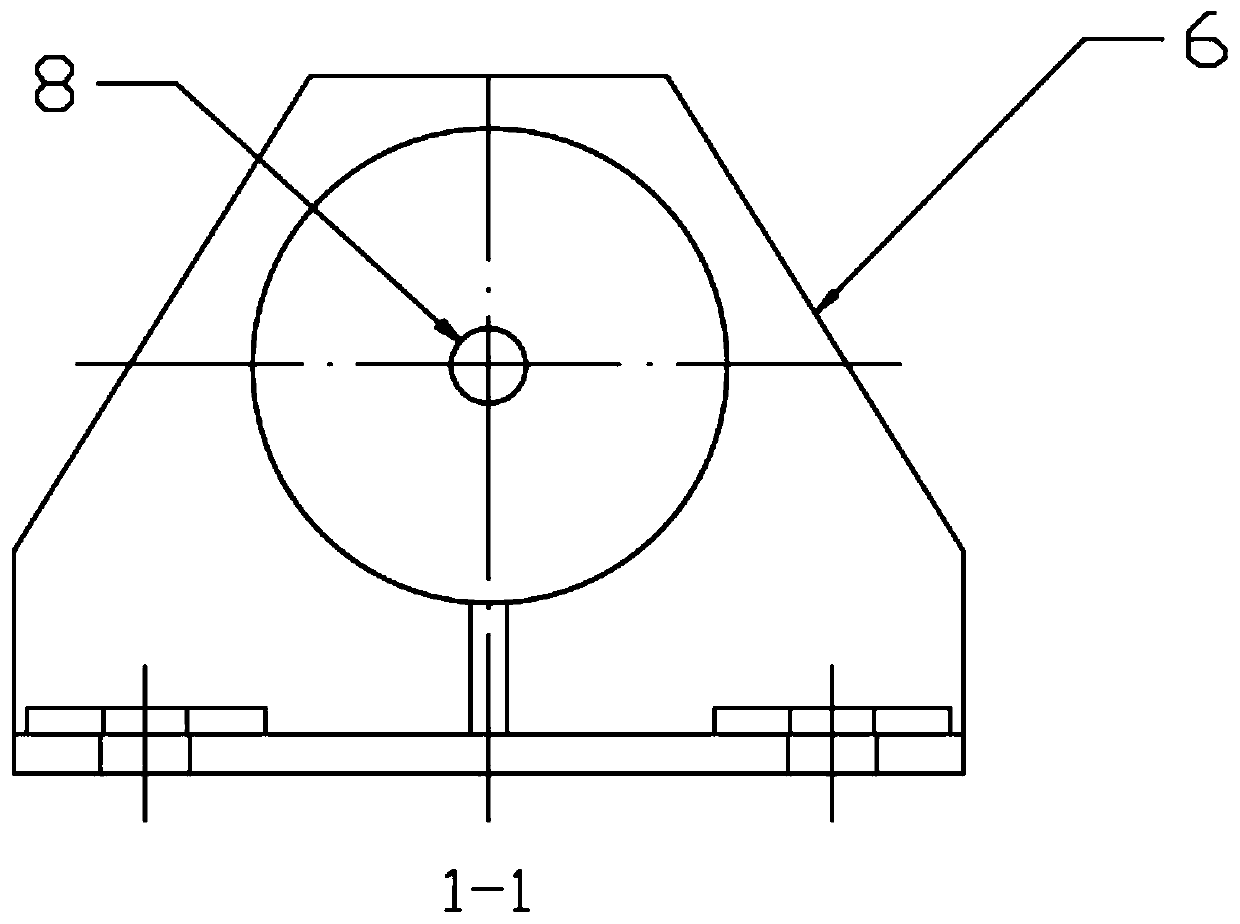

[0034] like Figure 5 , Image 6 As shown, in the technical solution disclosed in Embodiment 1, since the embedment depth of each frame column 1 relative to the site is the same, it is necessary to ensure that the distance between two adjacent frame columns 1 is equal along the slope direction of the site, so as to be able to The common use of the actual leveling support, otherwise, when the distance between two adjacent frame columns 1 changes, the corresponding required leveling height will also be different, resulting in the leveling support cannot be used universally, and in the construction process on site In some cases, the actual demand for leveling cannot be met. In this embodiment, the following structure is used to design the leveling support, as follows:

[0035]The leveling support also includes a bearing body 10, the bearing body 5 is slid on the bearing body 10 along the direction of gravity, and a rhombus jack 11 is arranged between the bearing body 10 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com