Vacuum preloading reinforcement construction method suitable for underwater silt environment

A construction method and environmental technology, applied in geotextiles, soil protection, infrastructure engineering, etc., can solve problems such as large amount of silt excavation and filling, ecological environment pollution, and impact on marine aquaculture, and achieve large excavation workload, The effect of high project cost and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

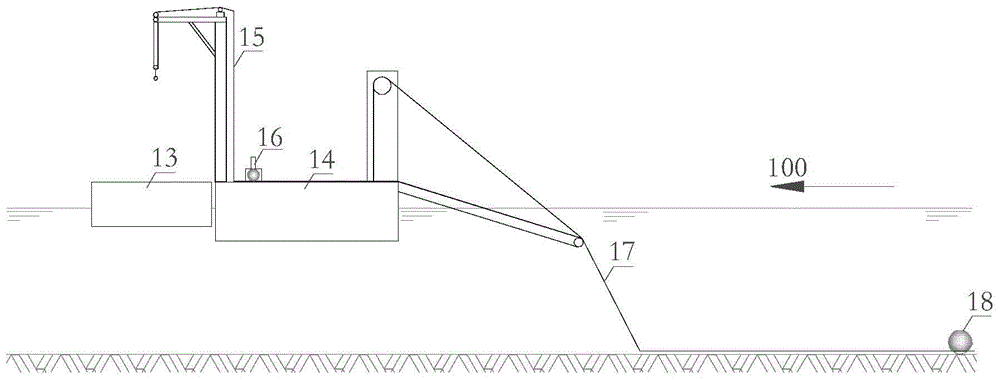

[0060] The present invention is implemented according to the following steps:

[0061] (1) Remove and level the sundries on the surface of the soft foundation 19 to be reinforced that affect the construction work; the sundries here refer to sharp and massive objects.

[0062] The towing ship 7, the sand carrier 13 and the laying ship 14 are positioned by the GPS system.

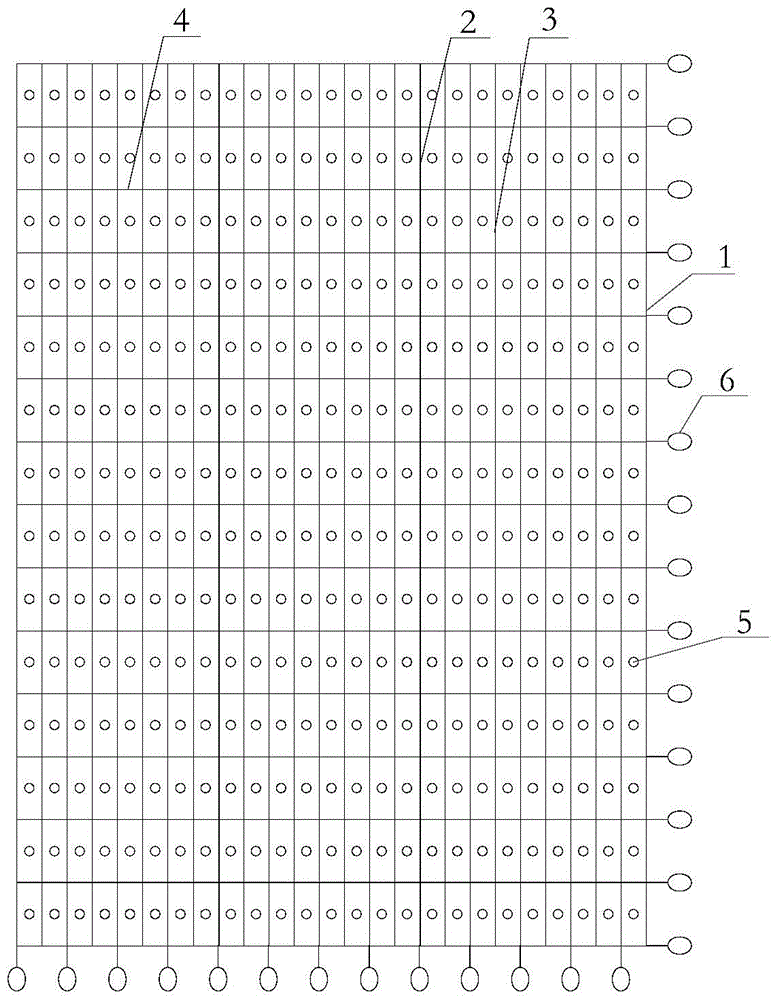

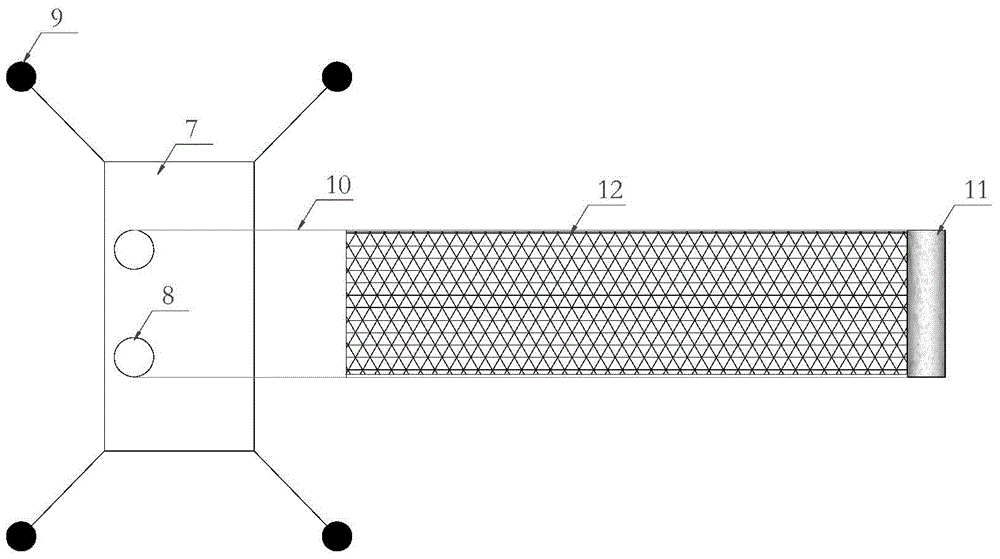

[0063] (2) Prepare materials to make the sand quilt soft body row 17, and the sand quilt soft body row is spliced into a whole by a plurality of filled sand bags respectively from longitudinal and transverse sequential connections and filled with mortar. The filling sand bag is sewn with upper and lower layers of geosynthetic material 1, and a plurality of longitudinal partition walls are evenly spaced between the upper and lower layers of geosynthetic material 1 to divide the inner cavity of the filling sand bag into a plurality of longitudinal compartments 2; A plurality of filling cuffs 5 are evenly arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com