Control method for washing machine

A control method and technology of a washing machine, applied to the control device of the washing machine, other washing machines, washing devices, etc., can solve problems such as inability to wet or wash or defoam clothes, cross-infection, and inability to realize circular spraying, etc., to achieve improved cleanliness degree, enhance the washing effect, and facilitate the washing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

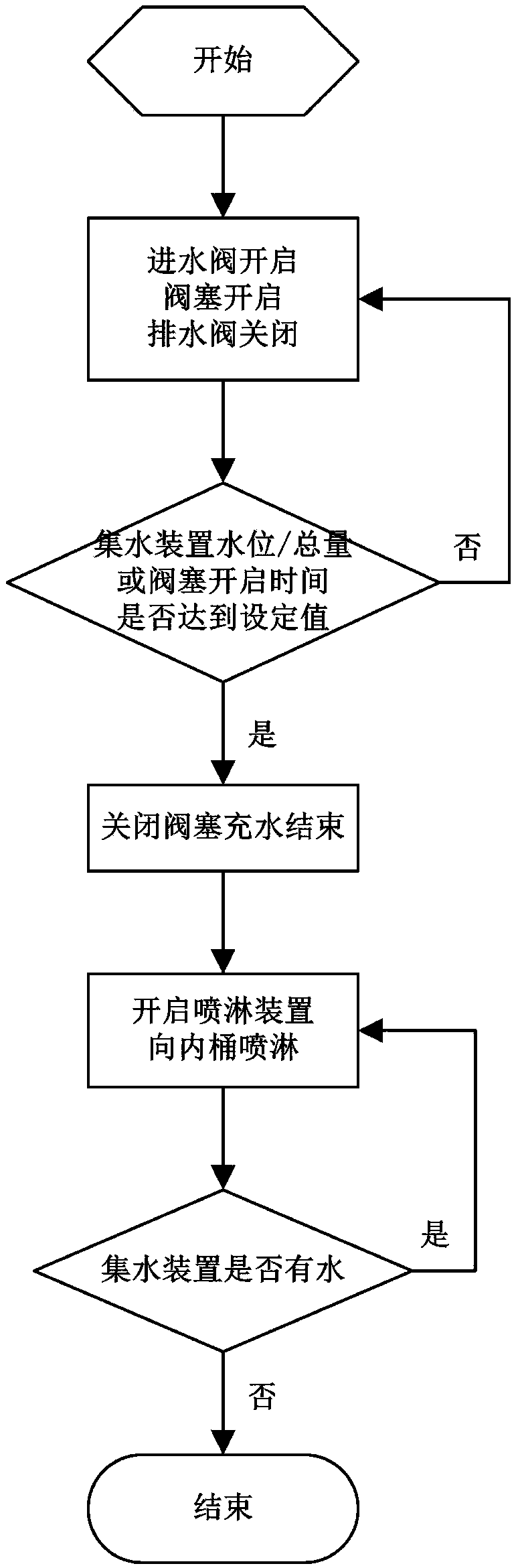

[0059] This embodiment is the spray control method of washing machine water inlet process, such as figure 2 shown.

[0060] During the process of water intake into the washing machine, since the clothes are not soaked at this time, the main purpose of spraying during this process is to wet the clothes that are not soaked, so that the subsequent washing process can be carried out smoothly.

[0061] When the washing machine needs to perform spraying during the water intake process, the water inlet valve is open to supply water to the inner tub. Since the spray needs to fill the water collecting device, the valve plug is opened at this time, and the water in the inner tub flows to Between the inner tub and the water collection device, when the water volume in the water collection device meets the conditions, that is, when the water level / water volume in the water collection device or the opening time of the valve plug reaches the set value (the specific method is as described ab...

Embodiment 2

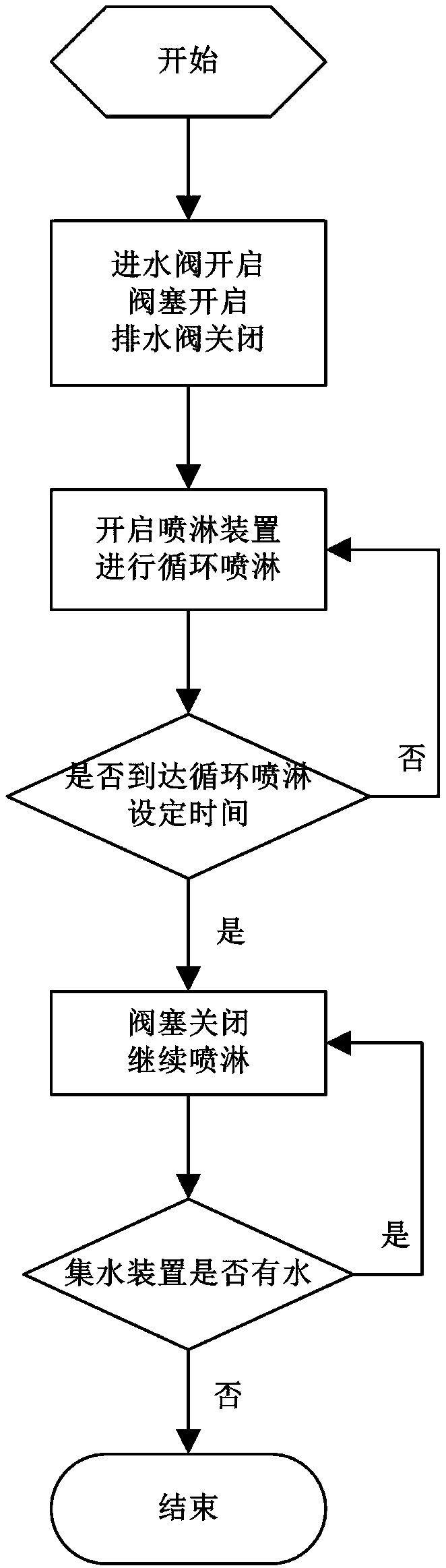

[0069] The difference between this embodiment and the previous embodiment is that there is a stage of cyclic spraying.

[0070] like image 3 As shown, during the water intake process, the water inlet valve is opened to feed water into the inner barrel, and the water in the inner barrel flows into the water collecting device through the drain hole at the bottom of the inner barrel when the valve plug is opened. At this time, there is water in the water collecting device, and there is water in the water collecting device In the case of a certain amount of water, the spraying device can be turned on. Different from the first embodiment, in the first embodiment, a certain amount of water is filled in the water collecting device, and this amount of water is sprayed. After the water is sprayed, it ends, and in this embodiment, the inner barrel, the water collecting device and the spraying pipeline are connected into a circular circuit for circulating spraying. limits.

[0071] A ...

Embodiment 3

[0078] This embodiment is a spray control method in the washing process, in which the clothes are washed / rinsed, and the pulsator is rotated.

[0079] like Figure 4 As shown, in the washing process, the pulsator washing machine mainly relies on the rotation of the pulsator to achieve the purpose of washing by the friction between the clothes and the inner tub and between the clothes. The pulsator rotates at the bottom of the inner tub to disturb the water flow and clothes. The clothes on the top are less impacted, and the clothes floating on the water surface may not be washed cleanly, but a spray device is set on the washing machine to wet the clothes before washing, and the clothes on the upper part of the inner tub are cleaned during the washing process. Shock, to play the function of further washing the clothes, in the washing process, the large amount of foam generated by the detergent can also be eliminated by spraying water to ensure a better washing effect.

[0080] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com