Preparation device and application of silicon carbide single crystal

A silicon carbide single crystal and preparation device technology, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems that the radial temperature cannot be detected in real time, and the quality of silicon carbide single crystal is high, so as to reduce the residual internal stress Large, small radial temperature gradient, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

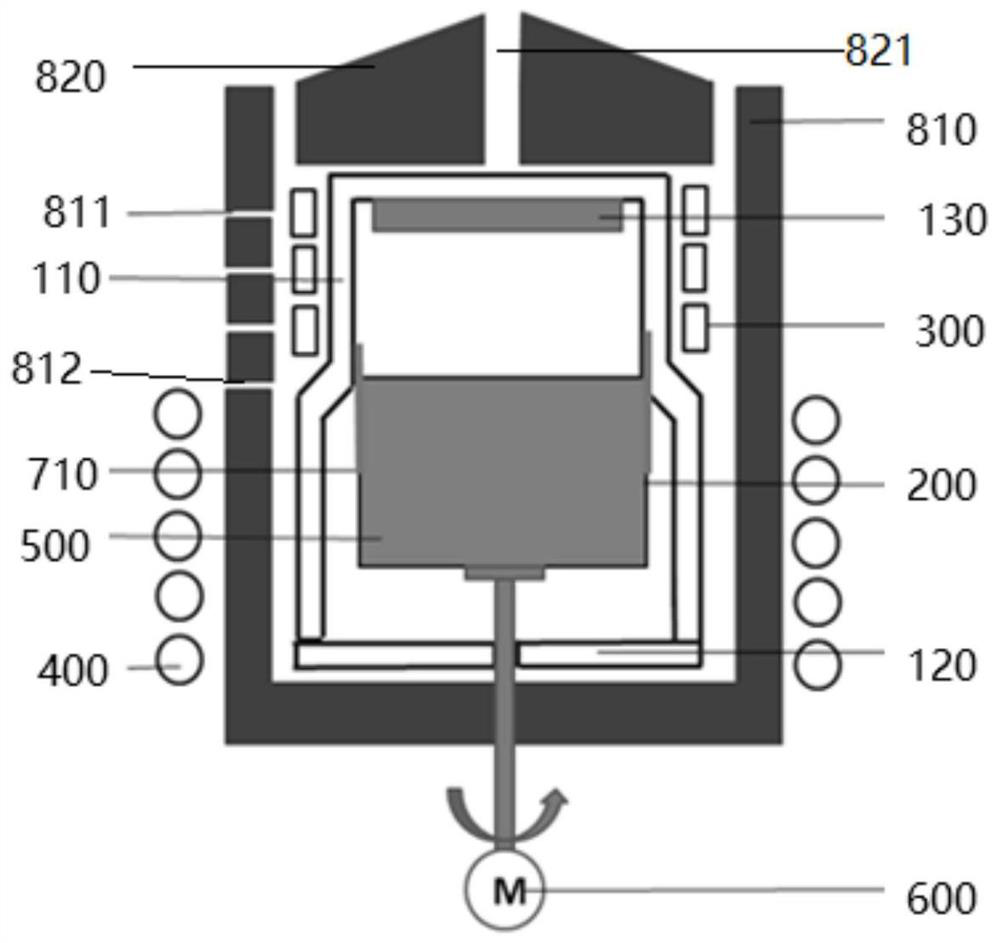

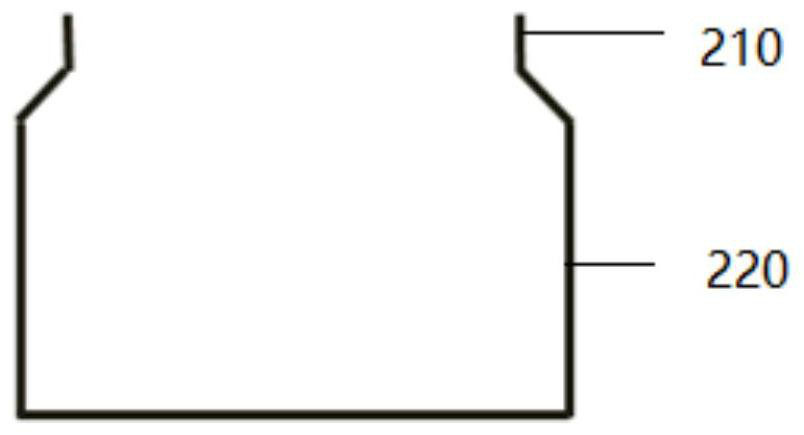

preparation example Construction

[0120] The method for preparing a silicon carbide single crystal using any of the above-mentioned preparation devices comprises the following steps:

[0121] 1) Assembly stage: After placing the raw materials in the charging barrel and fixing the seed crystal on the crucible cover, place the charging barrel in the rotating lifting unit in the crucible and connect it with the upper crucible in rotation, and assemble the heating unit and heat preservation structure;

[0122] 2) Heating stage: control the temperature of the top surface of the raw material to 2200-2800K, the temperature of the upper cover of the crucible to 1800-2000K, and the absolute pressure of the inert gas in the crucible to be 0.6×10 5 ~1.2×10 5 Pa, the flow rate of the inert gas is 50-500mL / min, the speed of the upward rotation of the charging barrel relative to the upper crucible is 0.2-2mm / h, and it is kept for not less than 6h;

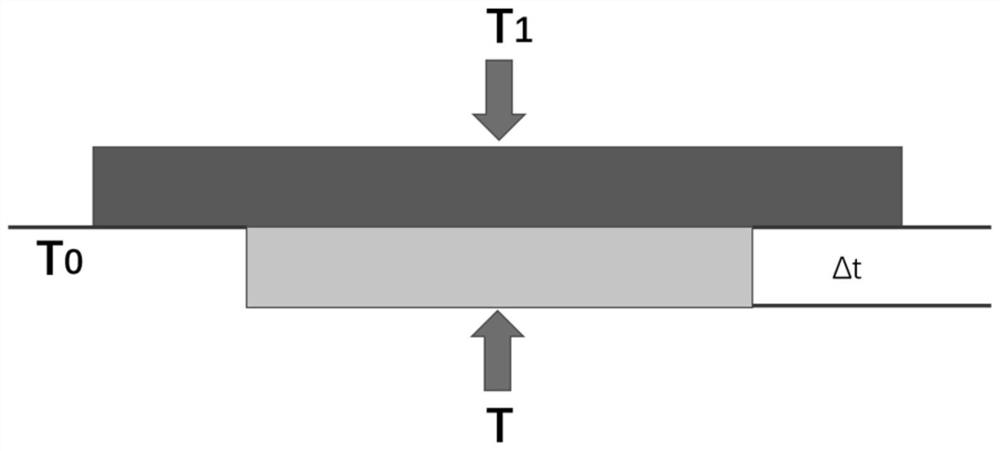

[0123] 3) Crystal growth stage: control the central temperature T1 of the ...

Embodiment 1

[0126] Example 1 Silicon carbide single crystal 1#

[0127] use reference figure 1 The preparation method of the silicon carbide single crystal 1# of the preparation device of the silicon carbide long crystal single crystal includes the following steps:

[0128] 1) Assembly stage: After placing the raw materials in the charging barrel and fixing the seed crystal on the crucible cover respectively, place the charging barrel in the rotating lifting unit in the crucible and screw it with the upper crucible to assemble the heating unit and heat preservation structure;

[0129] 2) Heating stage: control the temperature of the top surface of the raw material to 2400K, the temperature of the gas phase transmission zone to 1900K, and the absolute pressure of the inert gas in the crucible to be 0.8×10 5 Pa, the flow rate of the inert gas is 50-500mL / min, the rotation speed of the charging barrel relative to the upper crucible is 0.2mm / h, and keep for 10h;

[0130] 3) Crystal growth s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com