A luminous grounding wire and its processing technology

A grounding wire and fluorescent technology, which is applied in the direction of cable/conductor manufacturing, insulated cables, electrical components, etc., can solve the problems of luminous material reunion, affecting the luminous effect and stability of the grounding wire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

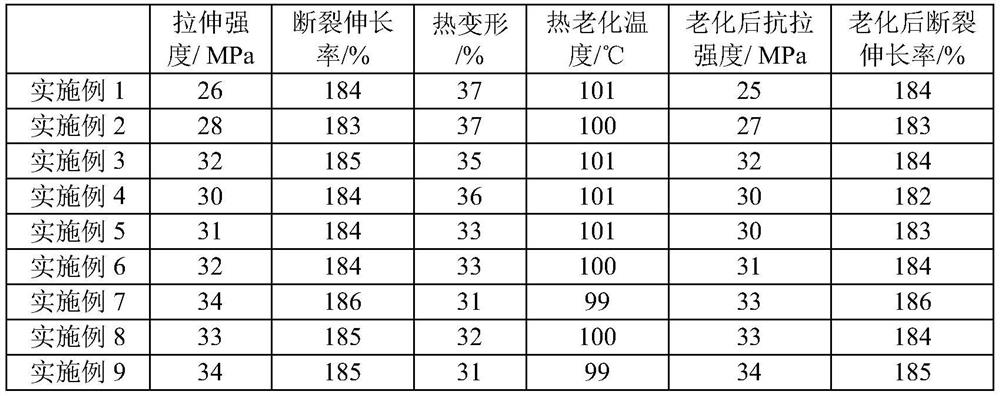

[0039] A luminous grounding wire includes a grounding wire body, the grounding wire body includes a copper core and an insulating sheath wrapping the copper core, the insulating sheath is wrapped with a fluorescent sheath, and the luminous grounding wire is processed by the following processing steps:

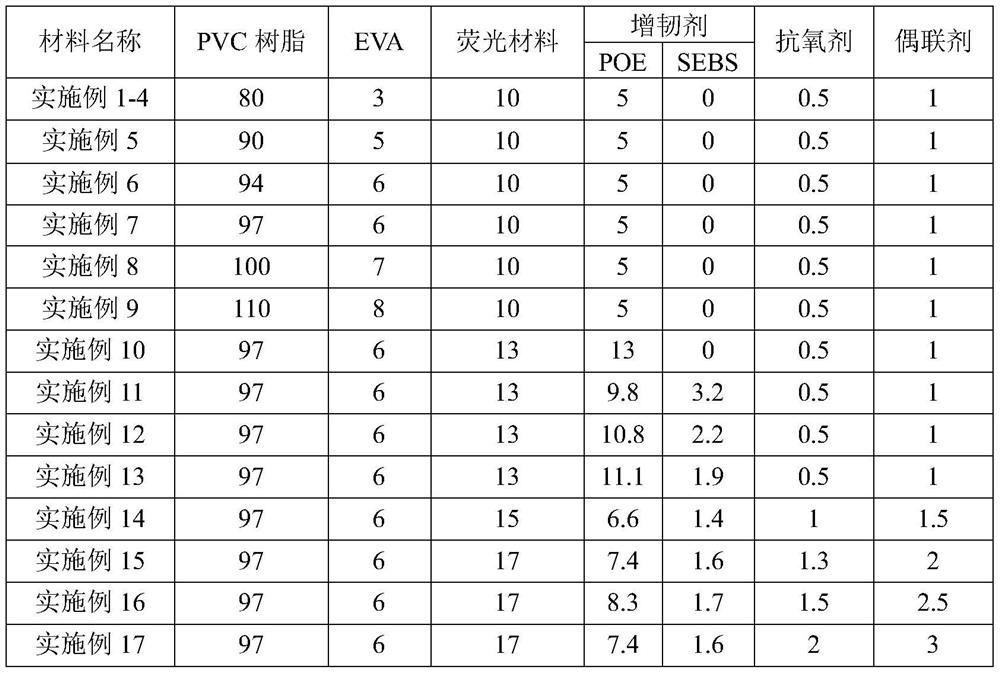

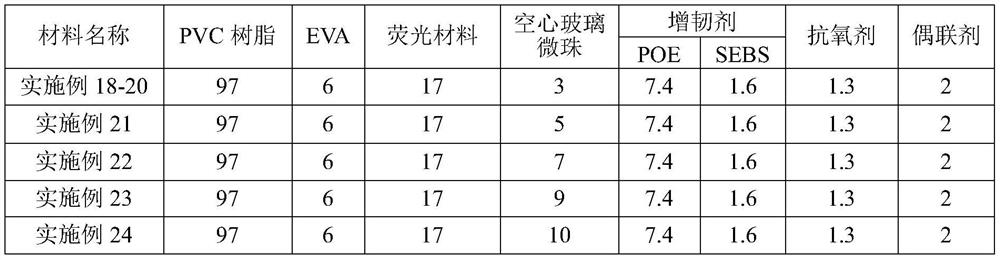

[0040] Preparation of fluorescent sheath material: According to the addition amount in Table 1, add polyvinyl chloride resin, ethylene-vinyl acetate copolymer, toughening agent, antioxidant and coupling agent into the internal mixer and mix for 10 minutes to 150 ℃ to obtain high-temperature material A; add fluorescent material to the above-mentioned high-temperature material A, banbury for 20 minutes to 160 ℃, obtain fluorescent sheath material, and set aside;

[0041] Preparation of luminous grounding wire: extrude the grounding wire body and the above fluorescent sheath material through a twin-screw extruder, then spray codes with a laser printer in turn, adjust the tension th...

Embodiment 2

[0043] A luminous grounding wire includes a grounding wire body, the grounding wire body includes a copper core and an insulating sheath wrapping the copper core, the insulating sheath is wrapped with a fluorescent sheath, and the luminous grounding wire is processed by the following processing steps:

[0044] Prepare the fluorescent sheath material: Add polyvinyl chloride resin, ethylene-vinyl acetate copolymer, toughening agent, antioxidant and coupling agent into the internal mixer according to the addition amount in Table 1 and mix for 13 minutes to 158 ℃ to obtain high-temperature material A; add fluorescent material to the above-mentioned high-temperature material A, banbury for 26 minutes to 167 ℃, obtain fluorescent sheath material, and set aside;

[0045] Preparation of luminous grounding wire: extrude the grounding wire body and the above fluorescent sheath material through a twin-screw extruder, then spray codes with a laser printer in turn, adjust the tension throug...

Embodiment 3

[0047] A luminous grounding wire includes a grounding wire body, the grounding wire body includes a copper core and an insulating sheath wrapping the copper core, the insulating sheath is wrapped with a fluorescent sheath, and the luminous grounding wire is processed by the following processing steps:

[0048] Preparation of fluorescent sheath material: Add polyvinyl chloride resin, ethylene-vinyl acetate copolymer, toughening agent, antioxidant and coupling agent into the internal mixer according to the addition amount in Table 1 and mix for 17 minutes to 164 ℃, to obtain high-temperature material A; add fluorescent material to the above-mentioned high-temperature material A, banbury for 30 minutes to 172 ℃, obtain fluorescent sheath material, and set aside;

[0049] Preparation of luminous grounding wire: extrude the grounding wire body and the above fluorescent sheath material through a twin-screw extruder, then spray codes with a laser printer in turn, adjust the tension th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com