Auxiliary steel bar pulling tool for neckband rubber-coated product

A technology of encapsulation and products, used in springs/shock absorbers, vibration suppression adjustment, mechanical equipment, etc., can solve the problem of easy vibration or falling from a high place, affecting the processing accuracy of the jig, and damage to the parts of the jig and other problems, to achieve the effect of good resilience, good cushioning, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

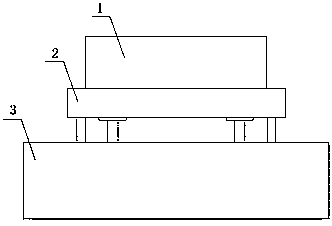

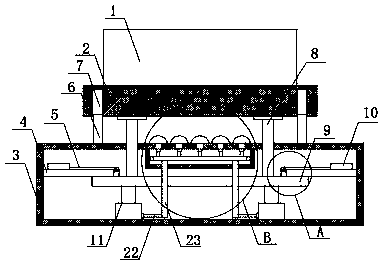

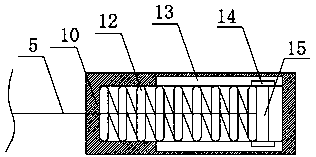

[0029] see Figure 1-6 , the present invention provides a technical solution: a neckband rubber-coated product auxiliary pulling steel bar jig, including a jig body 1, a base 2 and a support seat 3, the jig body 1 is fixedly installed on the upper end of the base 2, and the The base 2 is located above the support seat 3, the inner bottom of the support seat 3 is fixedly equipped with a buffer mechanism 11, and four groups of buffer mechanisms 11 are provided, and the upper ends of the four groups of the buffer mechanism 11 are fixedly equipped with a buffer plate 9, so The four corners of the upper end of the buffer plate 9 are fixedly equipped with support rods 8, and the top ends of the support rods 8 pass through the support base 3 and are fixedly connected to the bottom end of the base 2. The buffer mechanism 11 includes a sleeve 16 and a buffer rod 17. The buffer rod 17 is slidably installed inside the sleeve 16, the bottom end of the buffer rod 17 extends to the inside o...

Embodiment 2

[0036] see figure 1 , figure 2 , Figure 4 and Image 6 , the present invention provides a technical solution: a neckband rubber-coated product auxiliary pulling steel bar jig, including a jig body 1, a base 2 and a support seat 3, the jig body 1 is fixedly installed on the upper end of the base 2, and the The base 2 is located above the support seat 3, the inner bottom of the support seat 3 is fixedly equipped with a buffer mechanism 11, and four groups of buffer mechanisms 11 are provided, and the upper ends of the four groups of the buffer mechanism 11 are fixedly equipped with a buffer plate 9, so The four corners of the upper end of the buffer plate 9 are fixedly equipped with support rods 8, and the top ends of the support rods 8 pass through the support base 3 and are fixedly connected to the bottom end of the base 2. The buffer mechanism 11 includes a sleeve 16 and a buffer rod 17. The buffer rod 17 is slidably installed inside the sleeve 16, the bottom end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com