Polishing device for galvanized iron alloy door machining

A ferroalloy and mounting plate technology, applied in grinding drive devices, metal processing equipment, grinders, etc., can solve the problems of low efficiency of galvanized ferroalloy doors and inconvenient door turning, achieve fast clamping speed, reduce vibration and noise , Improve the effect of grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

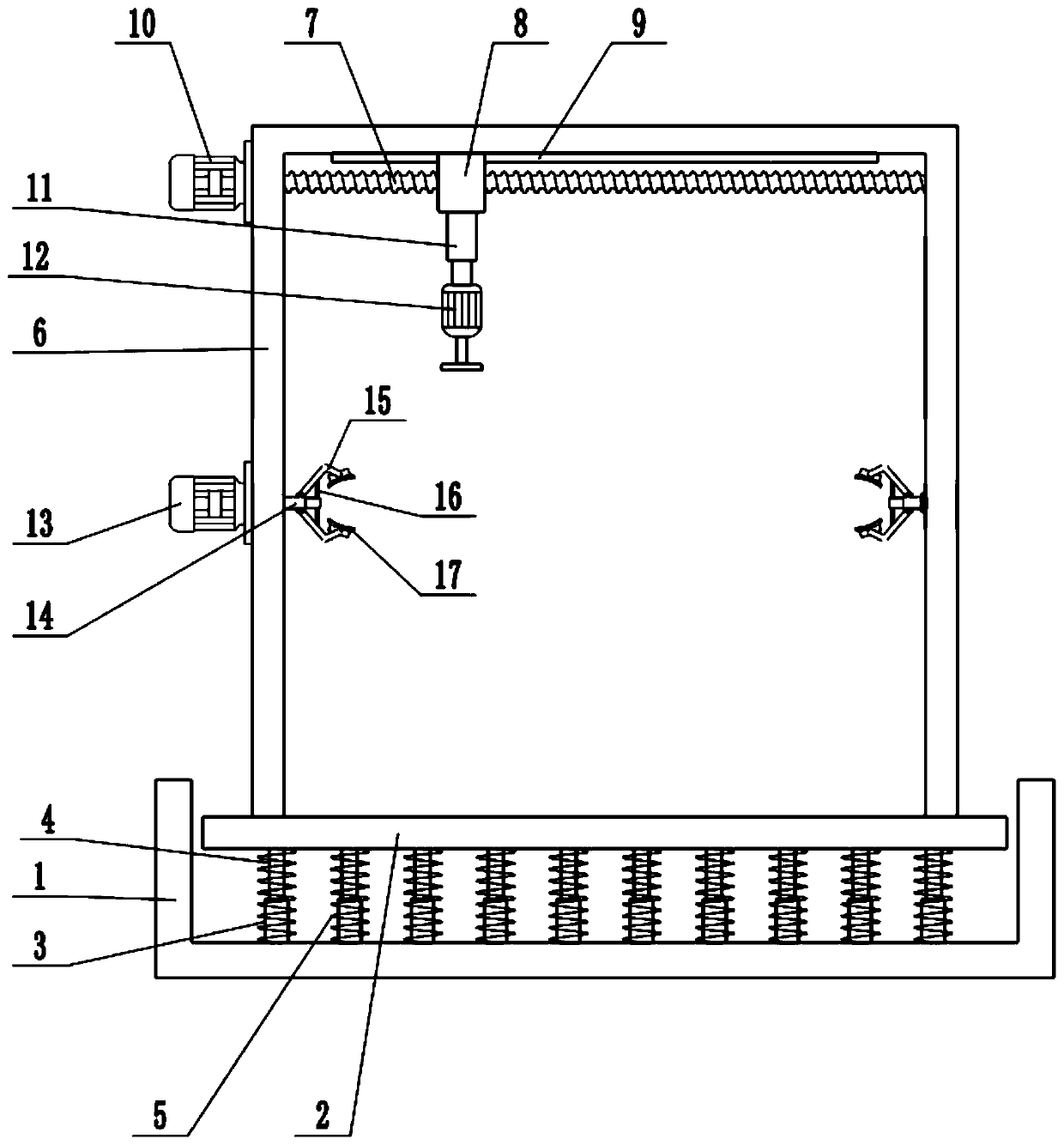

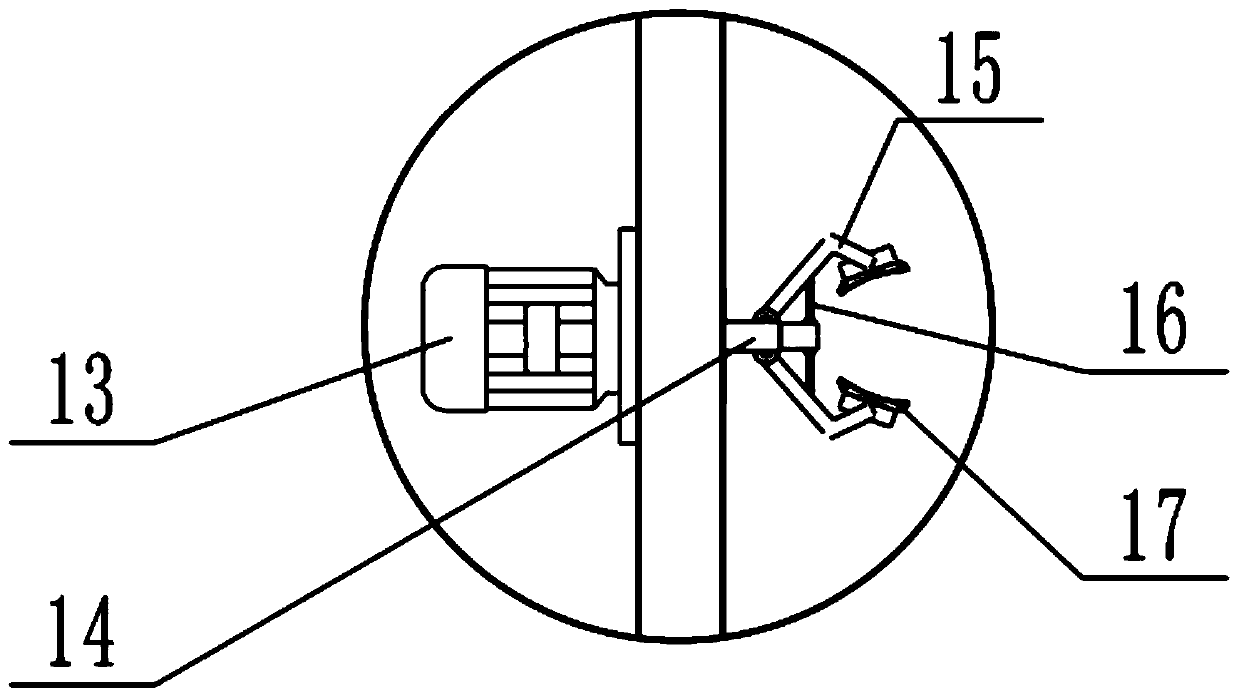

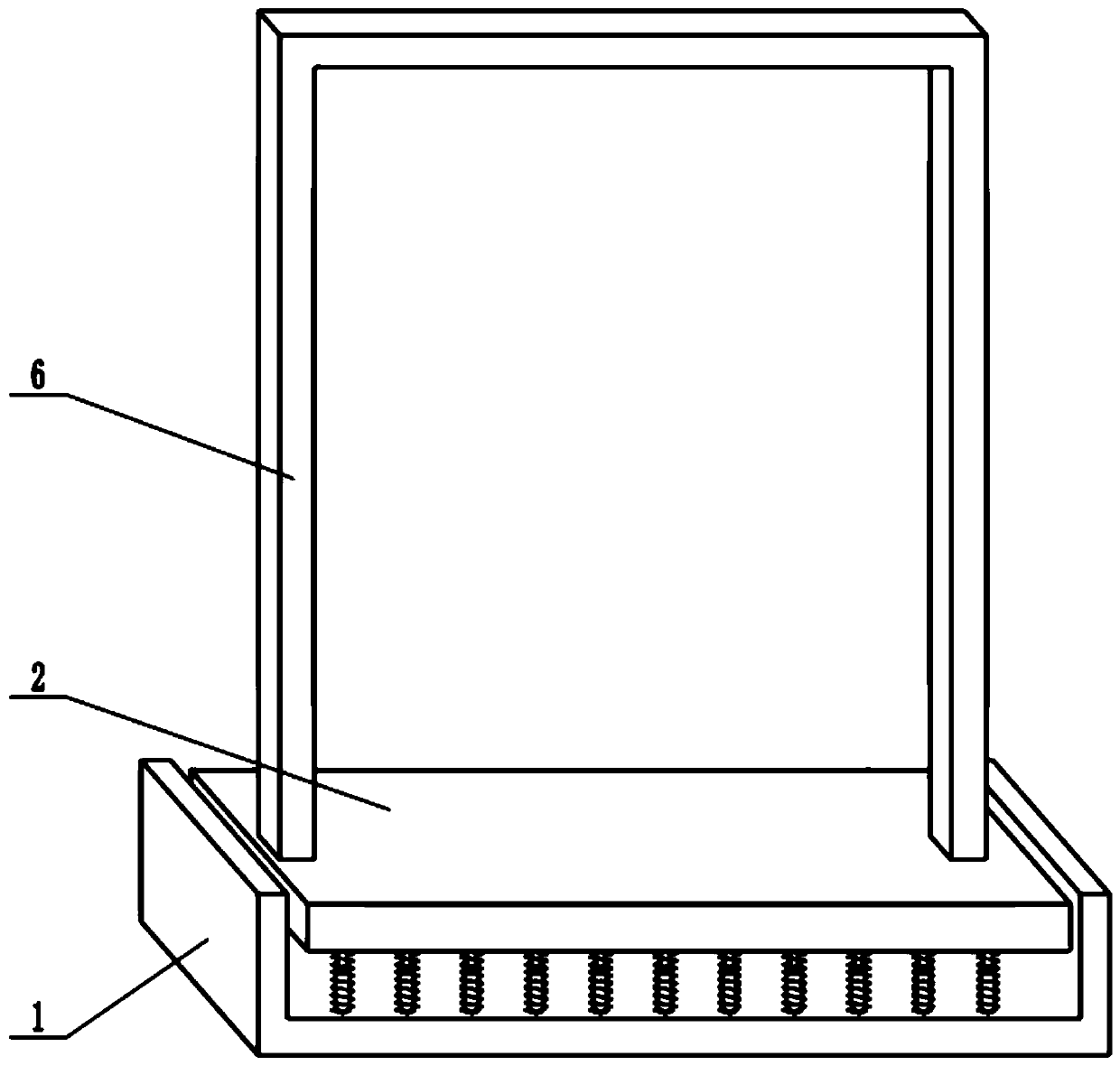

[0020] see Figure 1-3 , in an embodiment of the present invention, a grinding device for processing galvanized ferroalloy doors includes a base 1, a mounting plate 2, a fixing frame 6, an electric telescopic rod 11 and a grinding motor 12, and a mounting Plate 2, the upper surface of mounting plate 2 is fixedly connected with fixed frame 6, and the inside of fixed frame 6 is provided with screw mandrel 7, and the left and right ends of screw mandrel 7 are respectively connected with the side wall of fixed frame 6 in rotation, and the outside of fixed frame 6 The wall is fixedly connected with a translation motor 10, the translation motor 10 is a forward and reverse motor, the shaft extension end of the translation motor 10 is connected with the end of the screw rod 7, and the forward and reverse rotation of the translation motor 10 is controlled, which can drive the forward and reverse rotation of the screw mandrel 7 , the middle part of the screw rod 7 is provided with a sli...

Embodiment 2

[0022] On the basis of Embodiment 1, a sleeve 3 is fixedly connected to the upper surface of the base 1, and a guide column 4 is installed inside the sleeve 3, and the guide column 4 is slidingly connected with the sleeve 3, and the guide column 4 can slide along the sleeve 3 slide up and down, the top of the guide column 4 is fixedly connected with the mounting plate 2, the sleeve 3 is covered with a spring 5, the lower end of the spring 5 is fixedly connected with the upper surface of the base 1, and the upper end of the spring 5 is connected with the lower surface of the mounting plate 2. The surface is fixedly connected, and the spring 5 can be used for shock absorption to reduce the vibration of the mounting plate 2, thereby reducing the vibration and noise of the device during operation.

Embodiment 1、 Embodiment 2

[0023] Combined with Embodiment 1 and Embodiment 2, the working principle of the present invention is: place the galvanized iron alloy door to be polished between the two claws 15, control the extension of the hydraulic telescopic cylinder 14, and drive the two claws 15 to close together. Utilize the clamping plate 17 to clamp the galvanized iron alloy door to be polished, so as to facilitate the grinding operation, start the grinding motor 12, drive the grinding head to rotate, and control the extension of the electric telescopic rod 11, so that the grinding head and the surface of the door body are connected. The grinding head grinds the surface of the galvanized iron alloy door. When the door body needs to be turned over, the rotating motor 13 is controlled to run, and the clamping mechanism is driven to rotate, thereby driving the door body to rotate, which is convenient for adjusting the grinding position. The vibration of the mounting plate 2 is reduced, thereby reducing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com