Scrap collecting structure of water conservancy pipeline cutting device

A pipe cutting and water conservancy technology, applied in metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of inconvenient chip evacuation, inconvenient chip collection, and impact on collection efficiency, etc. Achieve the effect of preventing self-falling, increasing flexibility, and increasing collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

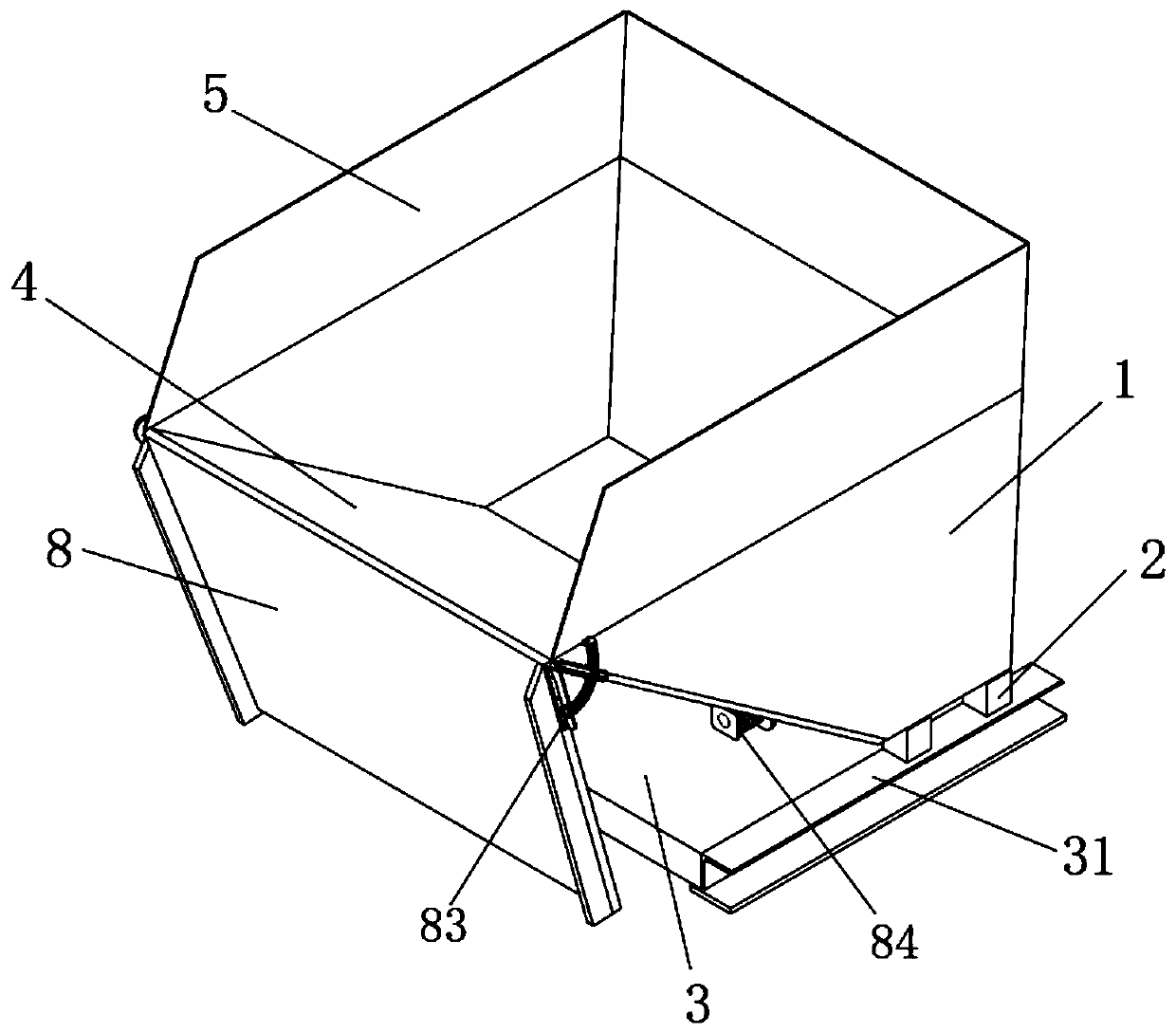

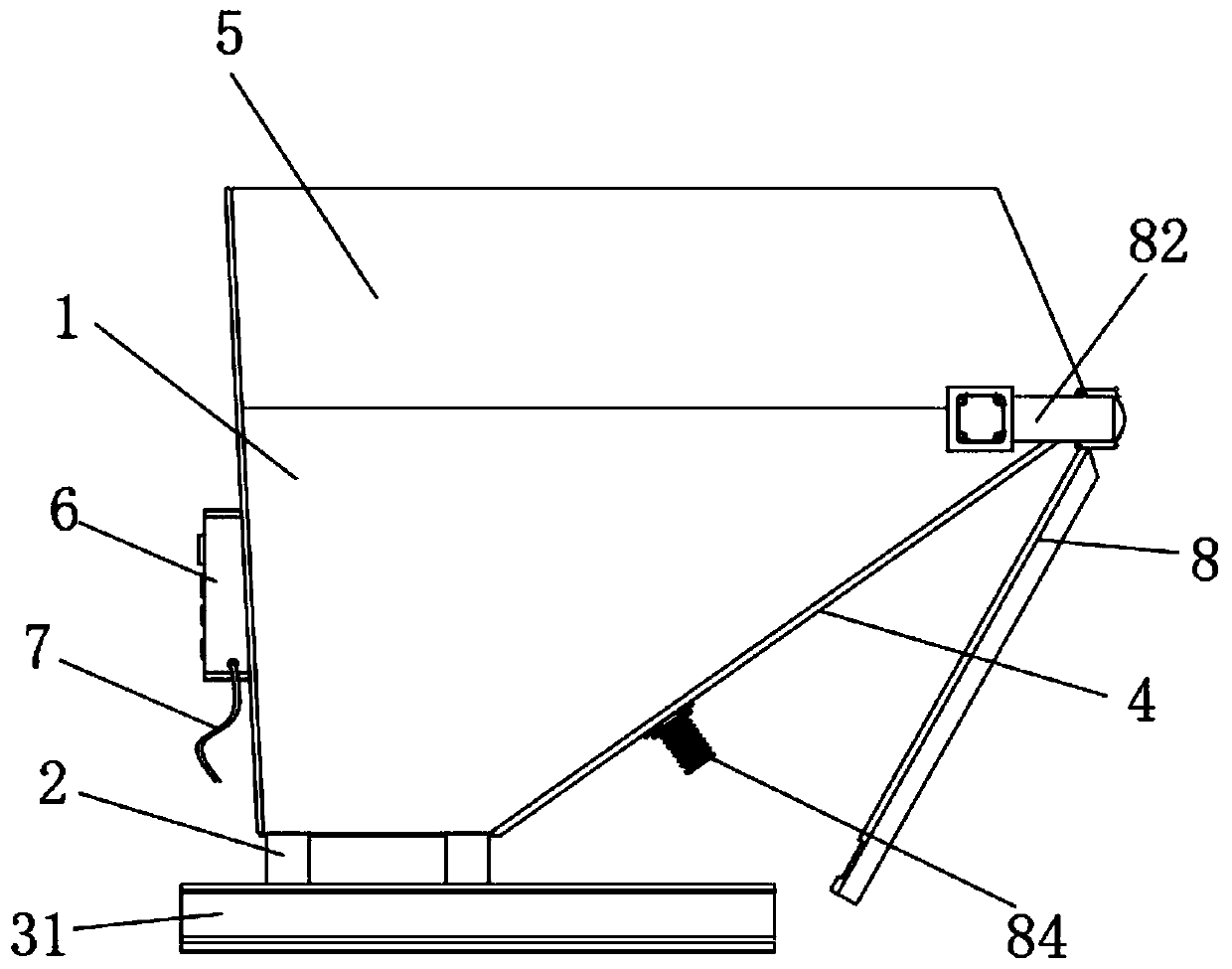

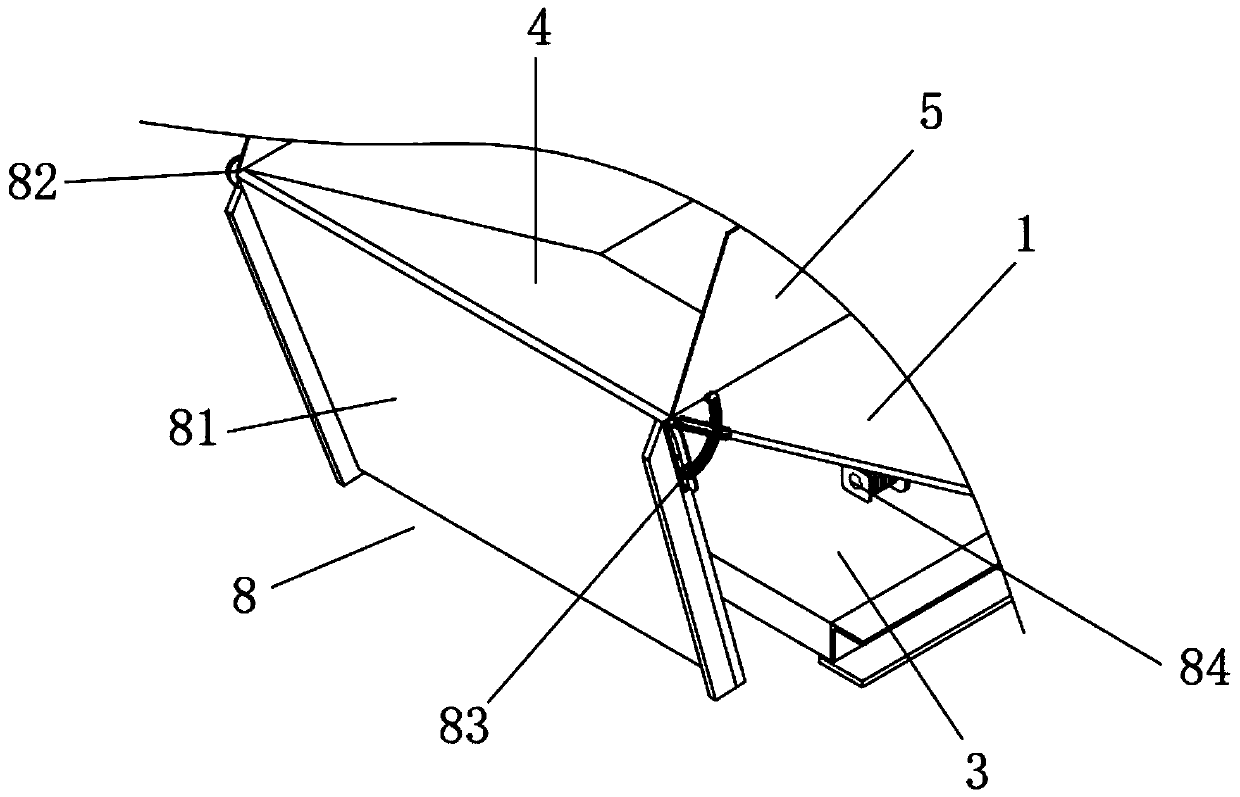

[0032] see Figure 1-2 As shown, the present invention provides a debris collection structure fire extinguisher fixing structure for a water conservancy pipeline cutting device through improvement, including a debris storage bin 1, a connecting bracket 2, a supporting base plate 3, a plate side frame 31, a chipping plate 4, Cover 5, control box 6, power cord 7 and auxiliary chip feeding mechanism 8, connecting brackets 2 are respectively provided on both sides of the bottom of the chip storage bin 1, a board side frame 31 is respectively provided at both ends of the support base plate 3, and the chip storage bin 1 The bottom is fixed with the plate side frame 31 supporting the side end of the bottom plate 3 through the connecting bracket 2. The front end of the chip storage bin 1 is a chip dropping plate 4 and is not an integral structure. In order to prevent debris from splashing out when falling, a control box 6 is provided in the middle of the rear end of the chip storage b...

Embodiment 2

[0038] The present invention provides a debris collection structure of a water conservancy pipeline cutting device through improvement. A storage battery is provided inside the control box 6, which can be charged and stored in advance through the power cord 7 to keep the equipment running. A groove is provided, and the groove matches the buffer plate 845 in the reset buffer structure 84, so that the auxiliary chip plate 81 corresponds to the buffer plate 845 when falling, and the buffer plate 845 absorbs the buffer force, and the driving motor 827 outputs The shaft is fixed to one end of the transmission shaft 826, and the other end of the transmission shaft 826 is fixed to the inner surface of the gear protection shell 824. After the drive motor 827 works, the transmission shaft 826 is driven to rotate by the output shaft, and the positioning frame bar 831 and the movable fork 833 bottom end surface is provided with installation fixed edge, is convenient to be fixed with chip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com