Auxiliary cutting equipment for 66kv on-site submarine cable processing for offshore wind power generation

A 66kv and submarine cable technology is applied in the field of auxiliary cutting equipment for 66kV in-field submarine cable processing for offshore wind power generation. Low equipment cost, easy repair and maintenance, and the effect of improving cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the invention is further illustrated in conjunction with the accompanying drawings and examples.

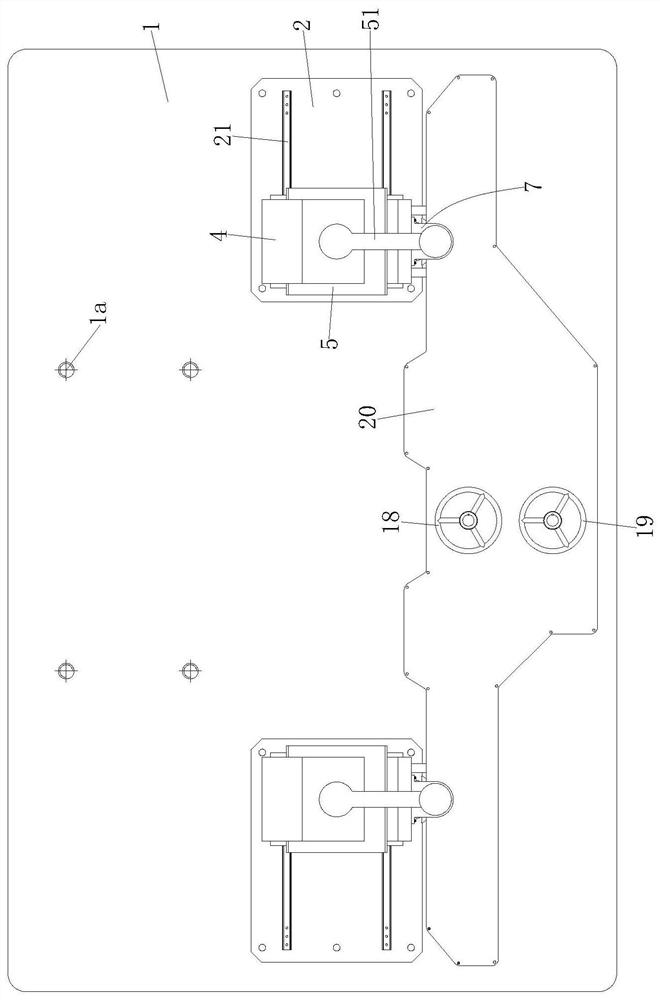

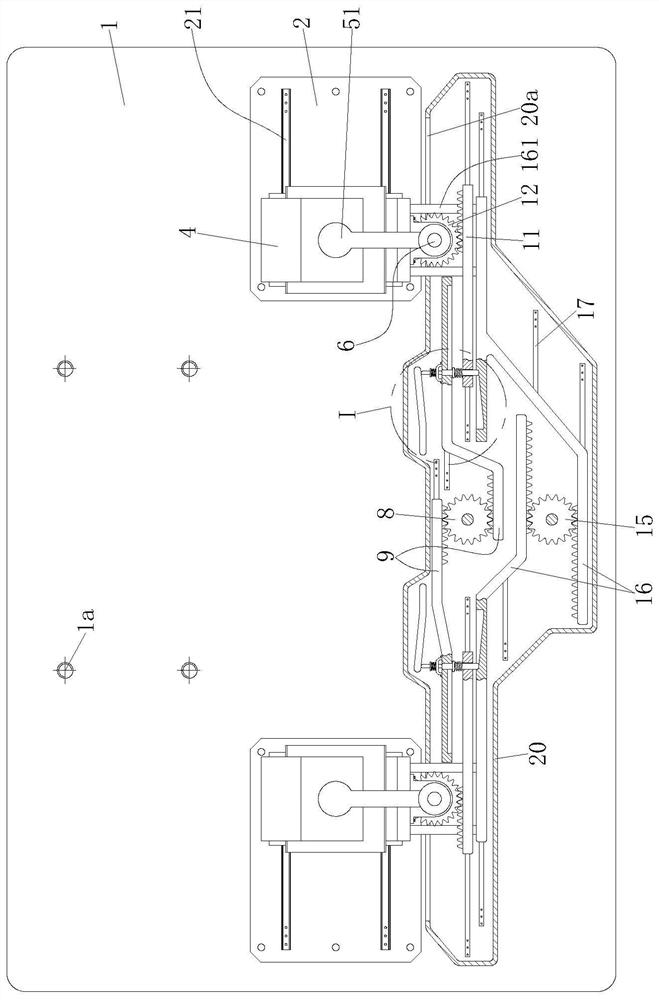

[0025] like Figure 1 to 5 As shown, the offshore wind power is used for auxiliary cutting equipment, including frame body 1, and the upper end portion of the frame body 1, the platform is opposite the left-right direction and is in the same center line. Mount 2, each mounting plate 2 is fixedly mounted on the platform by screws, and each mounting plate 2 is slidably equipped with a clamping mechanism, and the two clamping mechanisms are also in the same centerline.

[0026] like figure 1 , figure 2 and image 3 Design, the front side of the frame body 1 is provided with a protective casing 20, and four threaded mounting holes 1A for fixing the cutting device are provided on the rear side of the frame body 1. The protective enclosure 20 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com