A production method based on 5g communication optical fiber

A production method and optical fiber technology, which are applied in the production field based on 5G communication optical fiber, can solve the problems of cutting edge shaking and offset, low production efficiency, and difficulty in guaranteeing the transmission rate, etc., so as to increase the cutting quality, increase production efficiency, and quickly Effective fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

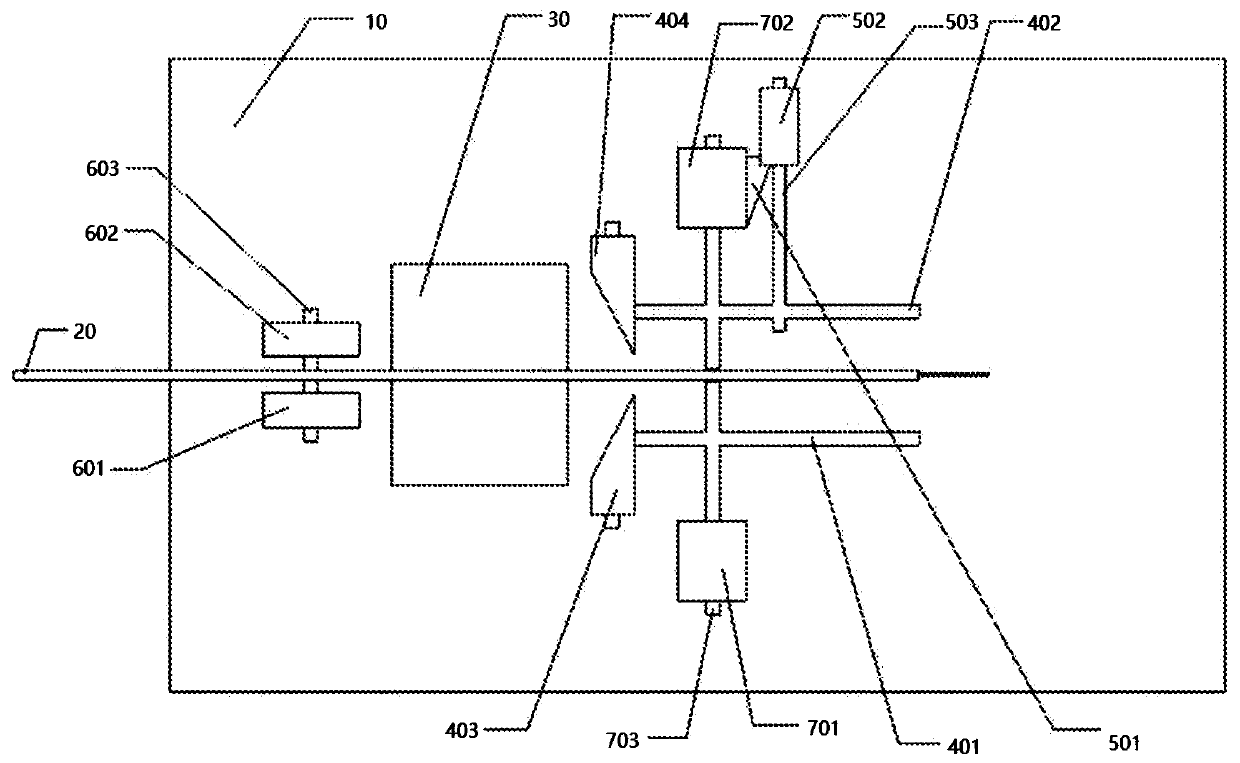

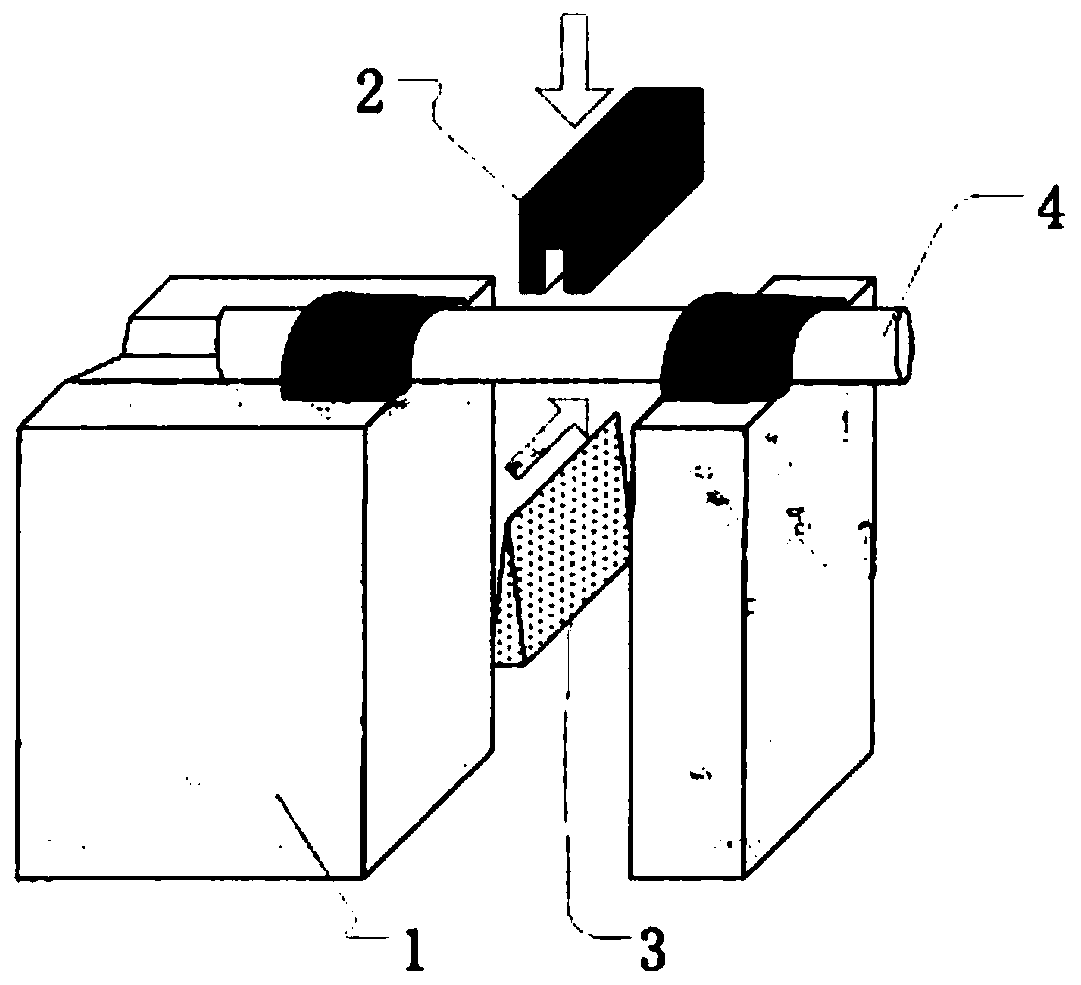

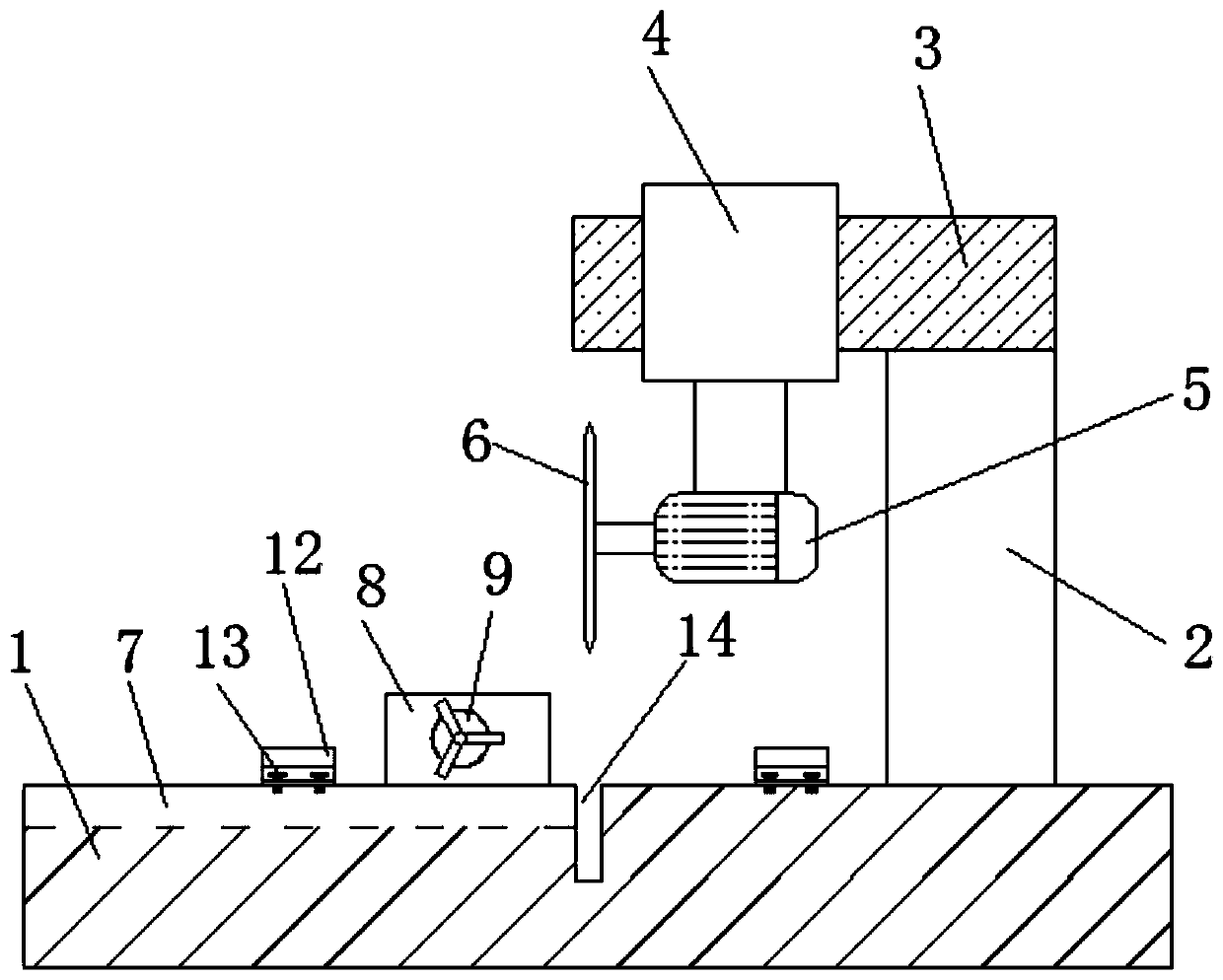

[0043] see Figure 6 , a production method based on 5G communication optical fiber, the production method comprises the following steps:

[0044] S1. Placement of optical fibers: Insert one or more optical fibers to be cut into the guide groove, and straighten and lay them to facilitate subsequent fixation;

[0045]S2. Preliminary fixation: clamp the hoop on both sides of the guide groove, then pre-fix the two sides of the hoop with bolts, and then rotate the threaded rod to make the clamping plate move relative to each other until the clamping plate and the optical fiber to be cut Preliminary fixation of the optical fiber to be cut can ensure that the optical fiber at the cutting position will not shake and shift during subsequent cutting, and will not affect the normal cutting;

[0046] S3. Fully fix: Slowly pre-tighten the bolts on both sides of the hoop one by one until the rear position of the optical fiber to be cut cannot be shaken, and further strengthen the fastening...

Embodiment 2

[0058] see Figure 6 , a production method based on 5G communication optical fiber, the production method comprises the following steps:

[0059] S1. Placement of optical fibers: Insert one or more optical fibers to be cut into the guide groove, and straighten and lay them to facilitate subsequent fixation;

[0060] S2. Preliminary fixation: clamp the hoop on both sides of the guide groove, then pre-fix the two sides of the hoop with bolts, and then rotate the threaded rod to make the clamping plate move relative to each other until the clamping plate and the optical fiber to be cut Preliminary fixation of the optical fiber to be cut can ensure that the optical fiber at the cutting position will not shake and shift during subsequent cutting, and will not affect the normal cutting;

[0061] S3. Fully fix: Slowly pre-tighten the bolts on both sides of the hoop one by one until the rear position of the optical fiber to be cut cannot be shaken, and further strengthen the fastenin...

Embodiment 3

[0074] see Figure 6 , a production method based on 5G communication optical fiber, the production method comprises the following steps:

[0075] S1. Placement of optical fibers: Insert one or more optical fibers to be cut into the guide groove, and straighten and lay them to facilitate subsequent fixation;

[0076] S2. Preliminary fixation: clamp the hoop on both sides of the guide groove, then pre-fix the two sides of the hoop with bolts, and then rotate the threaded rod to make the clamping plate move relative to each other until the clamping plate and the optical fiber to be cut Preliminary fixation of the optical fiber to be cut can ensure that the optical fiber at the cutting position will not shake and shift during subsequent cutting, and will not affect the normal cutting;

[0077] S3. Fully fix: Slowly pre-tighten the bolts on both sides of the hoop one by one until the rear position of the optical fiber to be cut cannot be shaken, and further strengthen the fastenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com