An anaerobic fermentation pretreatment system for fruit and vegetable waste

A technology of anaerobic fermentation, fruit and vegetable waste, applied in the direction of grain processing, etc., can solve the problems of overflowing water and oxygen, fermentation influence, inability to handle, etc., and achieve the effect of reducing factors affected by external forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to achieve the technical means of the present invention, the creation of features, to achieve the purpose and effect readily apparent understanding, the following embodiment with reference to specific embodiments, further illustrate the present invention.

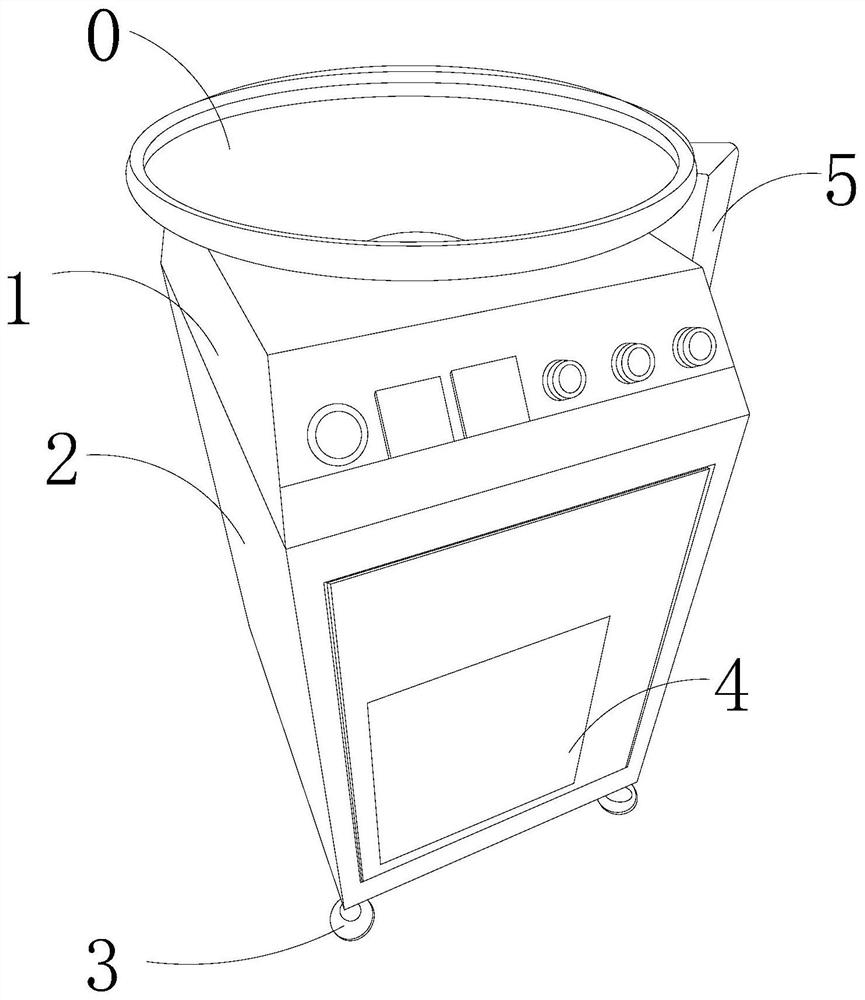

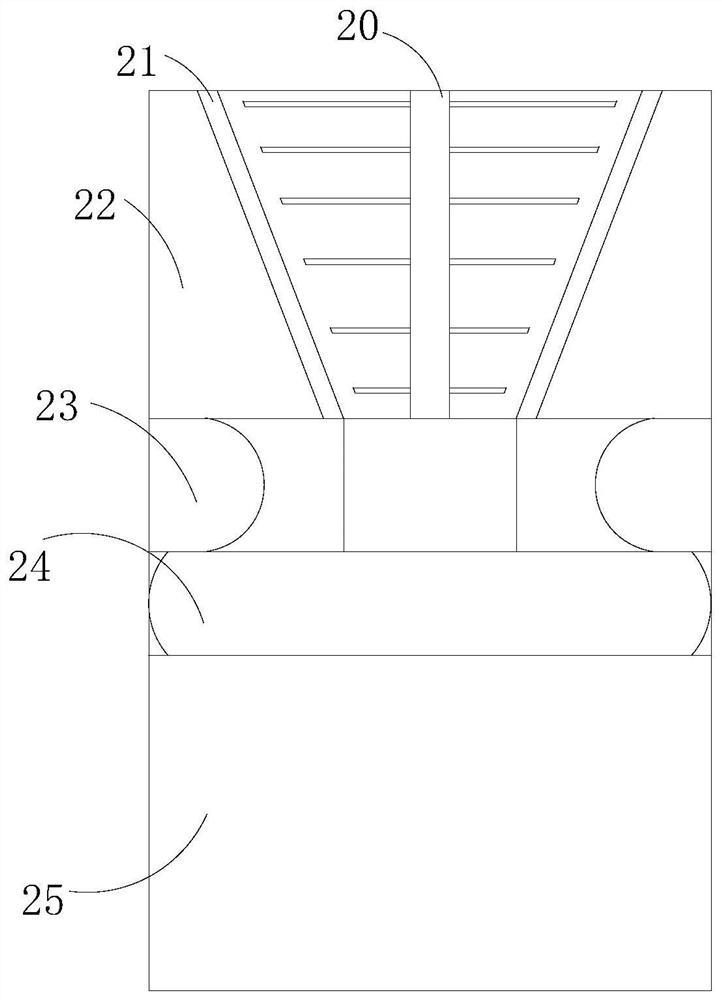

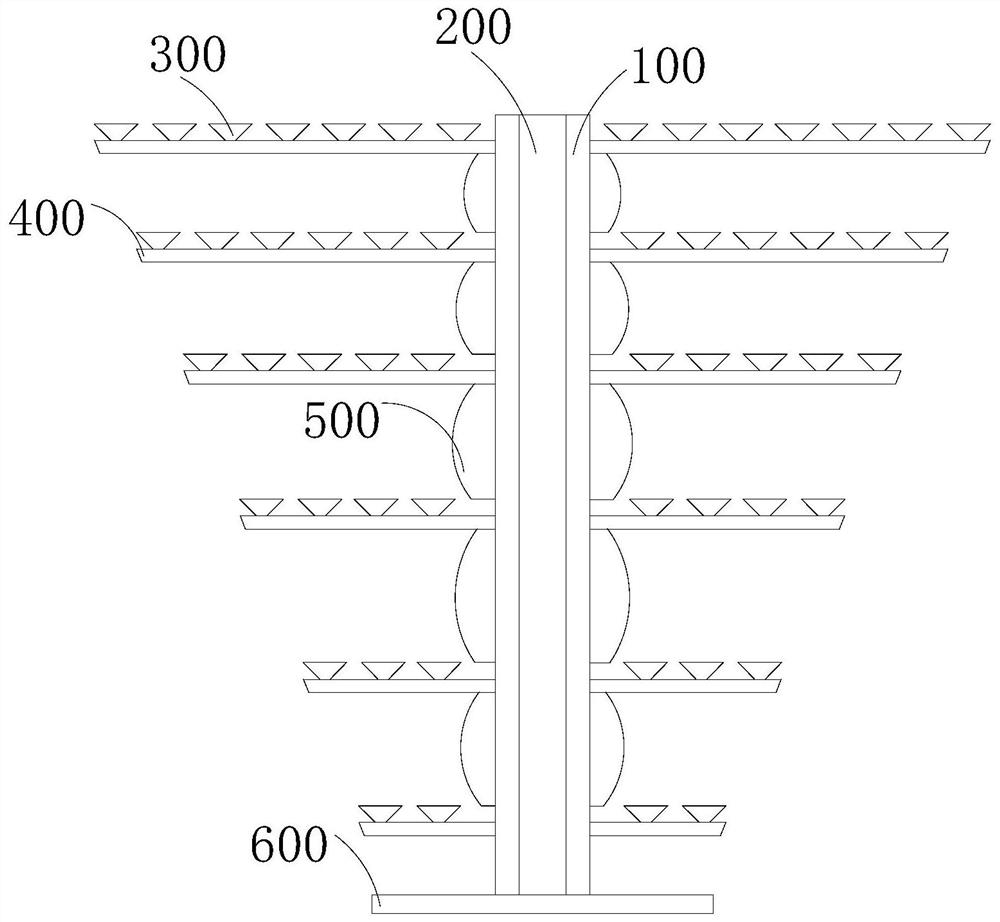

[0025] See figure 1 The present invention provides an anaerobic fermentation vegetable refuse pretreatment system: the structure comprises a feed chamber 0, control cabinet 1, the pre-processing of the fermentation cabinet 2, a telescopic pedestal 3, discharge chamber 4, the water conduit 5, the inlet 0 screwed feed chamber central control cabinet 1 above, the water conduit 5 is screwed on the right side of the feed chamber and the 0 pre-processed together with the fermentation cabinet 2 welding, the welding control cabinet 1 in the pre-processing of fermentation cabinet 2 above, the telescopic column is provided with four legs 3 and perpendicularly connected under pre-processed gum fermentation four corners of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com