Flue gas purification device used for incineration and capable of realizing efficient adsorption

A flue gas purification and high-efficiency technology, which is applied in the direction of combined devices, chemical instruments and methods, lighting and heating equipment, etc., can solve the problems of occupying large land, polluting land and groundwater resources, polluting the environment, etc., to reduce impurities and facilitate operation and maintenance , Improve the effect of processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

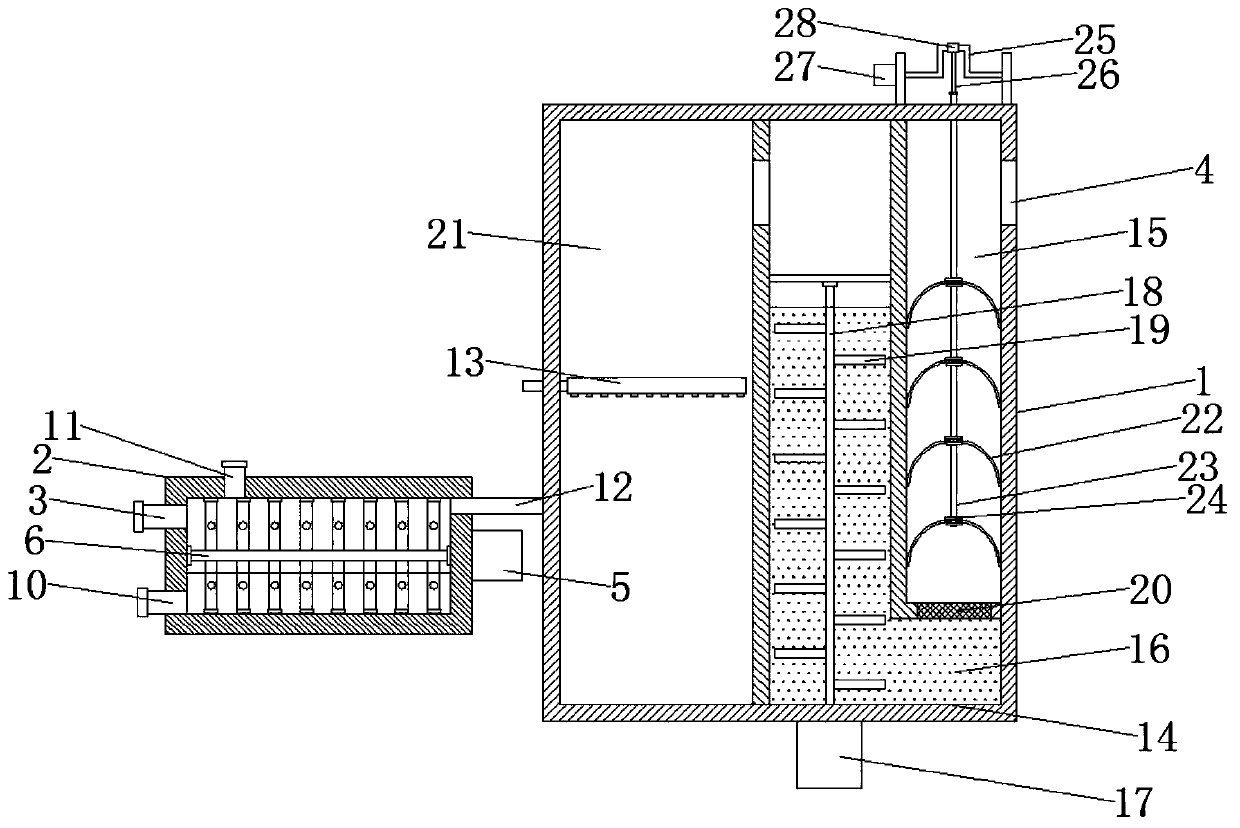

[0023] Please refer to the figure, in an embodiment of the present invention, a flue gas purification device for incineration with high-efficiency adsorption includes a housing 1, a heat exchange box 2, a smoke inlet pipe 3 and a smoke outlet 4; the smoke inlet pipe 3 communicates with the The left end of the horizontally arranged heat exchange box 2 is located on the upper part, and the flue gas produced by incineration is sent into the heat exchange box 2 from the smoke inlet pipe 3; a smoke outlet 4 is opened on the right side wall of the housing 1 to purify The final smoke is discharged from the device; the shell 1 communicates with the heat exchange box 2 through the ventilation pipe 12, and the ventilation pipe 12 is located at the upper right end of the heat exchange box 2, on the same level as the smoke inlet pipe 3, The other end of the ventilation pipe 12 is located in the middle of the housing 1 , so that smoke is sent into the housing 1 .

[0024] The central axis ...

Embodiment 2

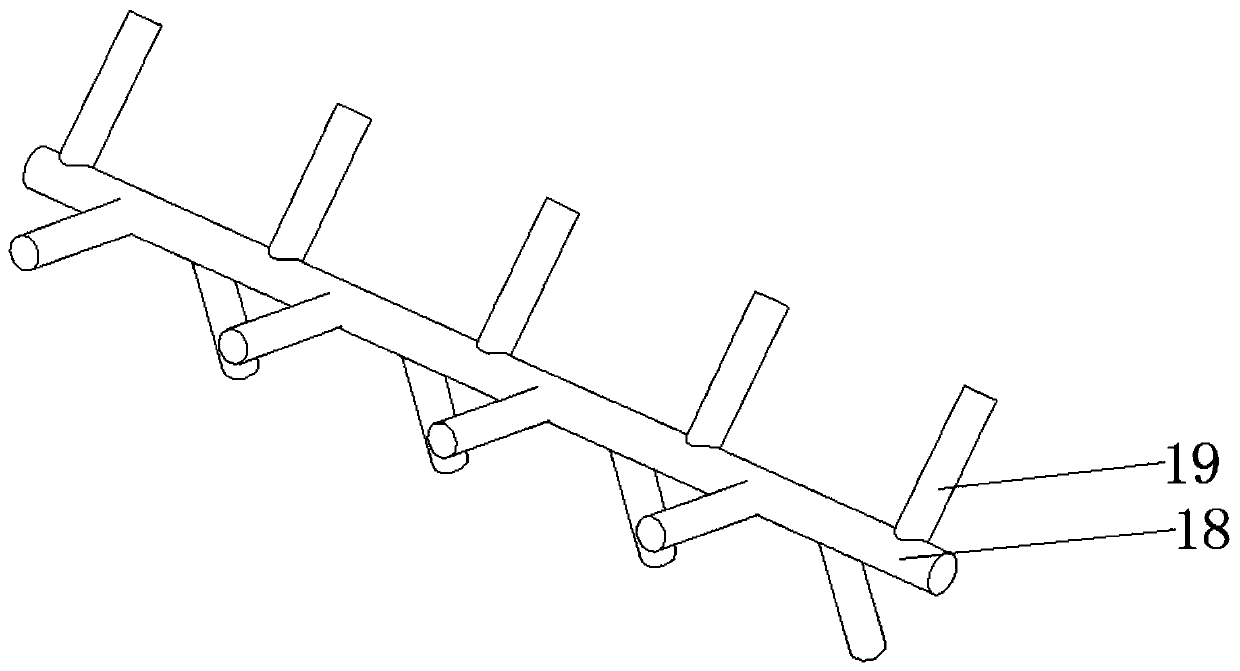

[0028]On the basis of Embodiment 1, an agitation mechanism is provided in the sand filter chamber 14, and the agitation mechanism includes a second motor 17, a second transmission shaft 18 and a toggle lever 19, and the second motor 17 is fixedly mounted on the casing 1, the output shaft of the second motor 17 extends vertically upwards into the sand filter cavity 14, and the output shaft of the second motor 17 is coaxially fixed with a vertical second transmission shaft 18, the second transmission The side wall of the shaft 18 is fixedly welded with several toggle levers 19, the toggle levers 19 are distributed from top to bottom, and the distance between two adjacent toggle levers 19 is 100-150 degrees, and the toggle levers of different heights 19 has improved the fluidity of interior sand gravel 16, is convenient to filter, and guarantees that impurity can not accumulate on the top of sand gravel 16 and block up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com