Anode assembly used for electroplating outside cylinder body tank

An anode component and anode technology, applied in the direction of electrodes, etc., can solve the problems of electroplating environmental impact, adverse effects of electroplating process, and affecting the final quality of products, etc., and achieve the effects of low total cost, easy guarantee of conductive effect, and avoiding loosening and desoldering failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

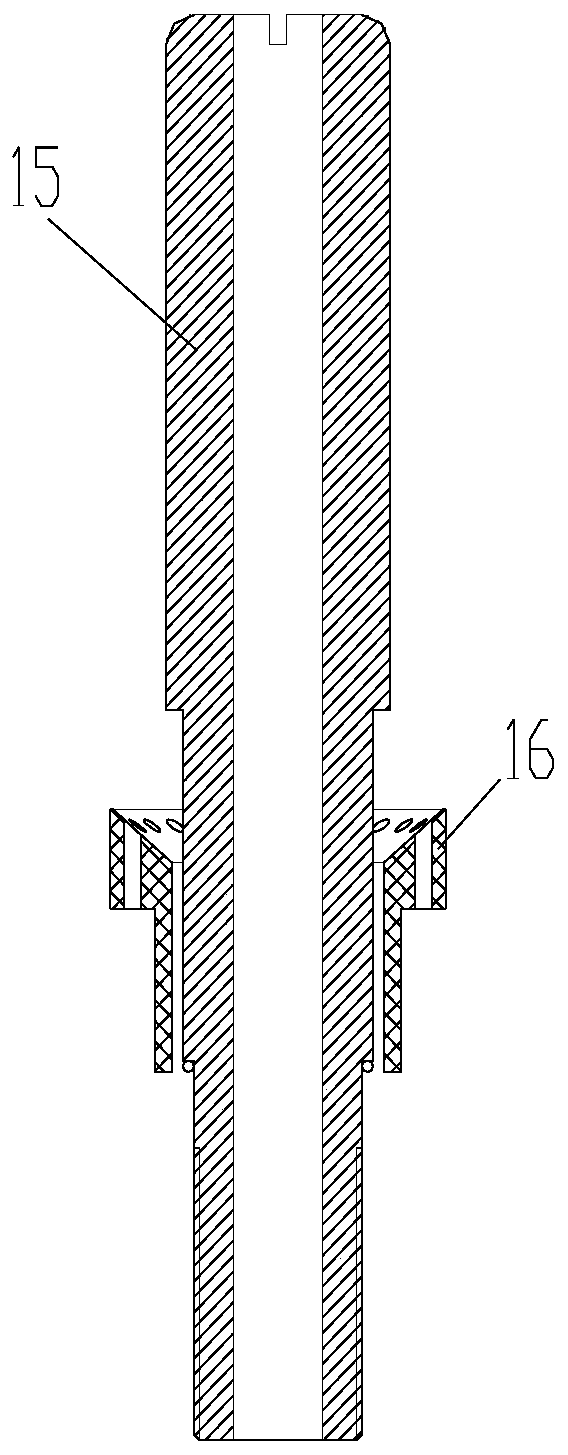

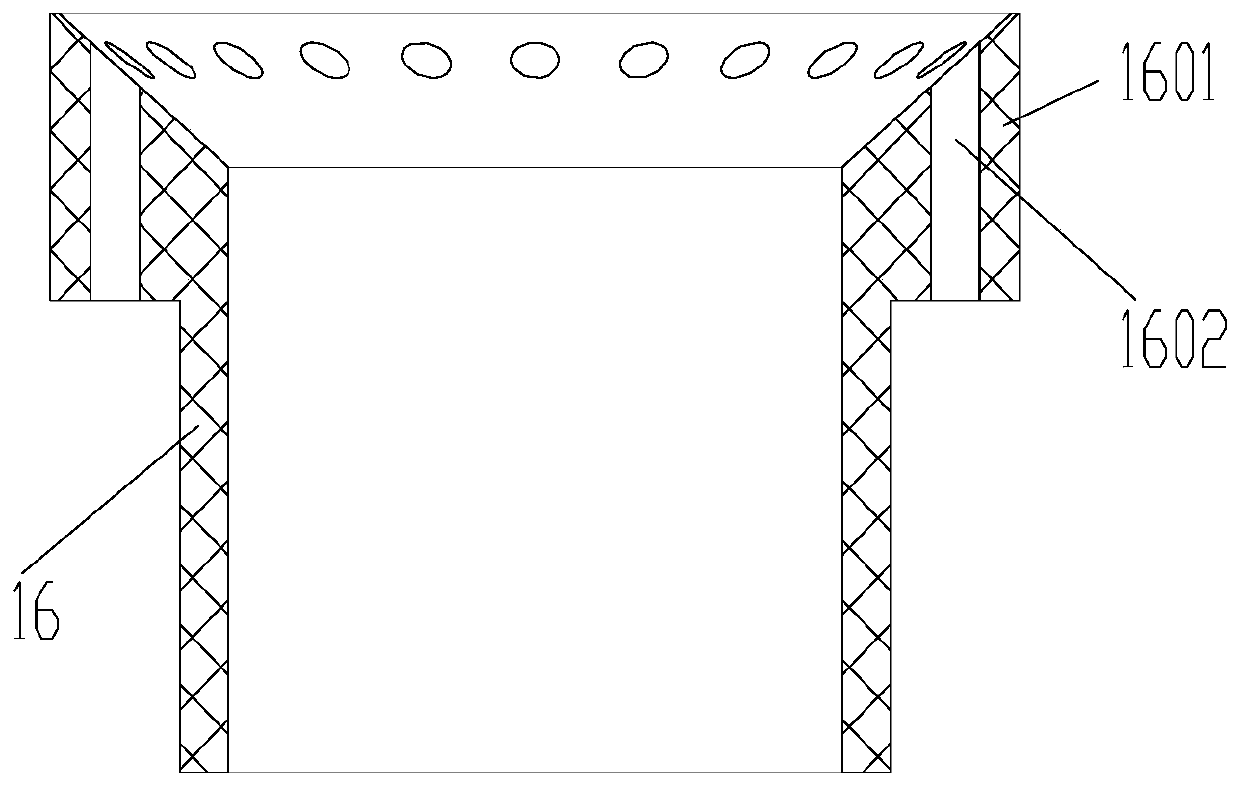

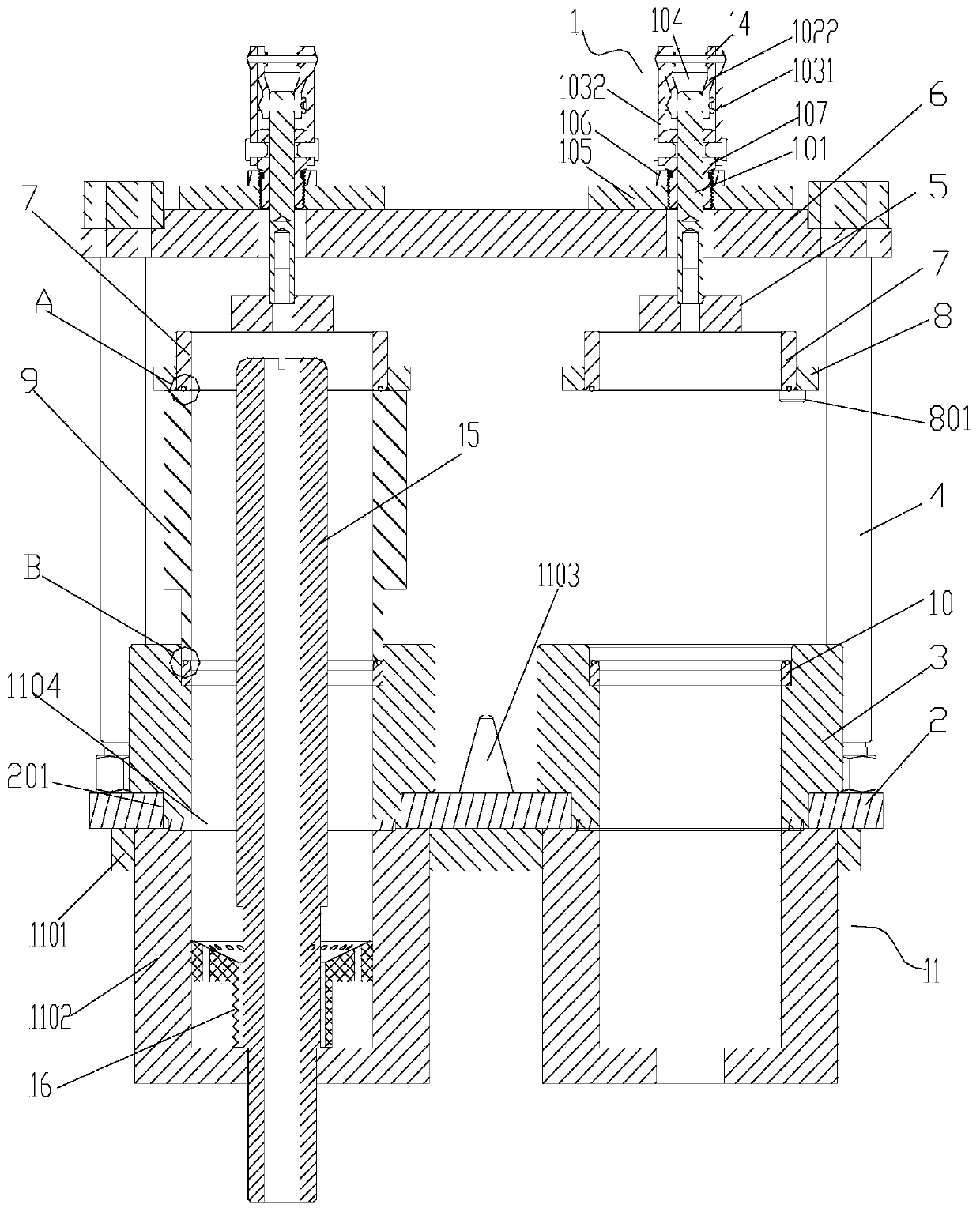

[0026] figure 1 It is a structural sectional view of the present invention, figure 2 is a sectional view of the deflector, image 3 It is a sectional view of the application structure of the present invention, Figure 4 for image 3 Enlarged view at A, Figure 5 for image 3 Enlarged view at B, Figure 6 It is the installation structure drawing of the present invention, Figure 7 is the structure diagram of the shroud, Figure 8 For the electroplating environment that the present invention is used for installation, form the structural stereogram (remove the anode), as shown in the figure: the anode assembly used for electroplating outside the cylinder tank of the present embodiment includes an anode 15 and a flow guide 16, and the guide The flow piece 16 is used to introduce the electroplating solution into the electroplating environment and flow into the center of the anode from the top of the anode and reflow;

[0027] The flow guide is provided with distribution ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com